Behind the Scenes at Northrop Grumman’s Aerothermal Research and Testing Facility

Northrop Grumman’s testing facility is one of the few private facilities in the U.S. that provide Mach 0-8+ testing capabilities, products and services that mimic some of the world’s thermal extremes and simulate environments faster than the speed of sound.

This critical testing continues to allow demonstration and validation of new advancements in supersonic and hypersonic systems.

Ironically, Not Everything About Mach Speed Is Fast

While there’s no doubt that products using hypersonic and supersonic technology will blaze past you without you even knowing it, the Northrop Grumman testing facility spends a lot of time ensuring safety and data collection are performed at just the right speeds. Actual tests times range from seconds to minutes, but the preparation for this testing involves years of expertise and a commitment to collaboration and innovative thinking.

Central Control Room — Testing Mach Speed

In 2018, our facility conducted nearly 200 tests. Our central control room monitors video feeds and activates safety features in our six test cells.

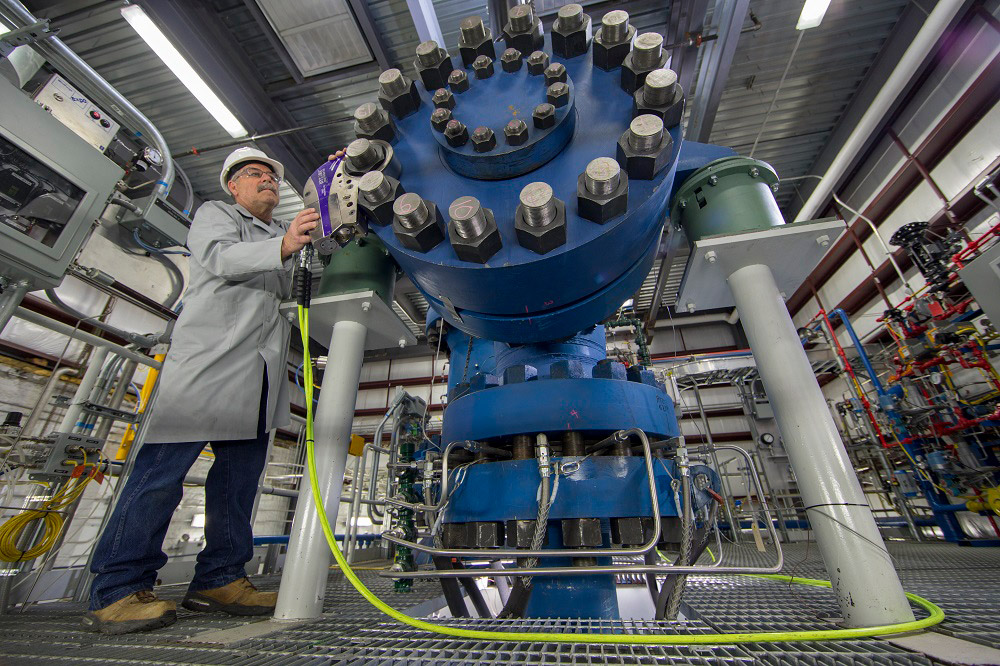

Vacuum Sphere and Ejector System

This 60,000-cubic-foot vacuum sphere and ejector system enables us to simulate altitude, supersonic flight and high Mach speeds during testing. We have run tests ranging from 20 seconds to 20 minutes to validate supersonic and hypersonic systems.

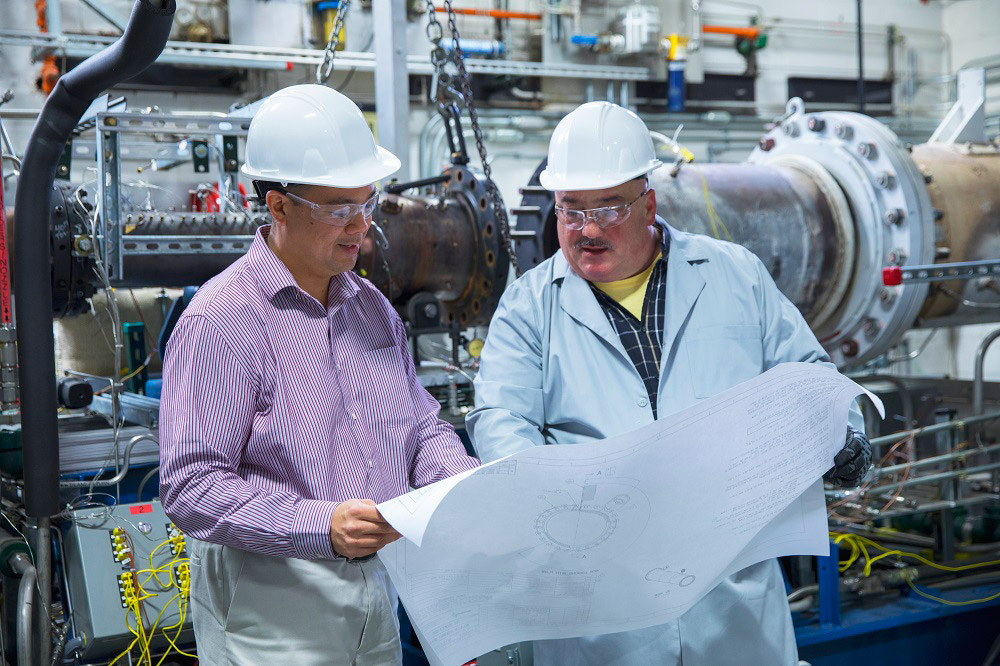

30 Days of Testing for Mach Speed

Design Engineer Troy and Test Technician John prepare to integrate the test article into one of our six test cells. Preparation and post-testing activities take time. The average test article spends 30 days in our facility executing its test matrix.

Instrumentation Check

“Our customers analyze the data we collect from their test articles during testing and rely on its integrity to make critical decisions. That’s why performing an instrumentation check prior to testing is so vital.” Dean, Testing Manager, and Rob, Chief Engineer

Simulating Mach 5-8 Conditions

“Our new Hypersonic Aeropropulsion Clean Air Testbed, or HAPCAT, will be revolutionary for testing hypersonic scramjet engines in simulated Mach 5-8 conditions for up to two minutes time.” Skip, Test Technician

Suppliers Are Critical to Achieving Mach Speed

“Our suppliers are our lifeblood at Northrop Grumman’s Aerothermal Research and Test Facility to ensure that we have the proper parts, equipment and maintenance in the right quantities, at the right time.” Erika, Procurement/Supply Chain

Our Northrop Grumman team of design and test professionals — including engineers, technicians, analysts, supply chain and more — work together every day to test speeds of Mach 0-8. Interested in working in a fast-paced environment? Search for jobs here.

Life at Northrop Grumman: Recent Stories

Shape your career journey with diverse roles and experiences that expand your expertise, feed your curiosity, and fuel your passion.

Life at Northrop Grumman: Archived Stories

It takes every one of us to make the impossible a reality. See what life is like at Northrop Grumman.