Northrop Grumman’s hydrotesting team ensures the durability of solid rocket motors which power missions to the moon and beyond.

Launching the Future

Mentor team tests solid rocket motors to propel development and production.

By Kenneth Kesner

Ben Iannuzzi is sure he has the best job ever.

“I test rockets!” Ben said. “The smoke and fire of a static test is amazing, but I also love the other testing we put rocket motors through to get to that point — vibration, thermal, humidity and more to be certain they will survive extreme conditions and still meet the demands of the mission.”

Ben is an energetics manufacturing test engineer at Northrop Grumman’s advanced and high-speed propulsion manufacturing facility in Elkton, Maryland. The site is also home to Northrop Grumman’s Hypersonic Capabilities Center and construction is under way on a new Propulsion Innovation Center. Energetics are solid or liquid materials that react and release energy that produces thrust. Energetics fuel the “smoke and fire” of a rocket engine.

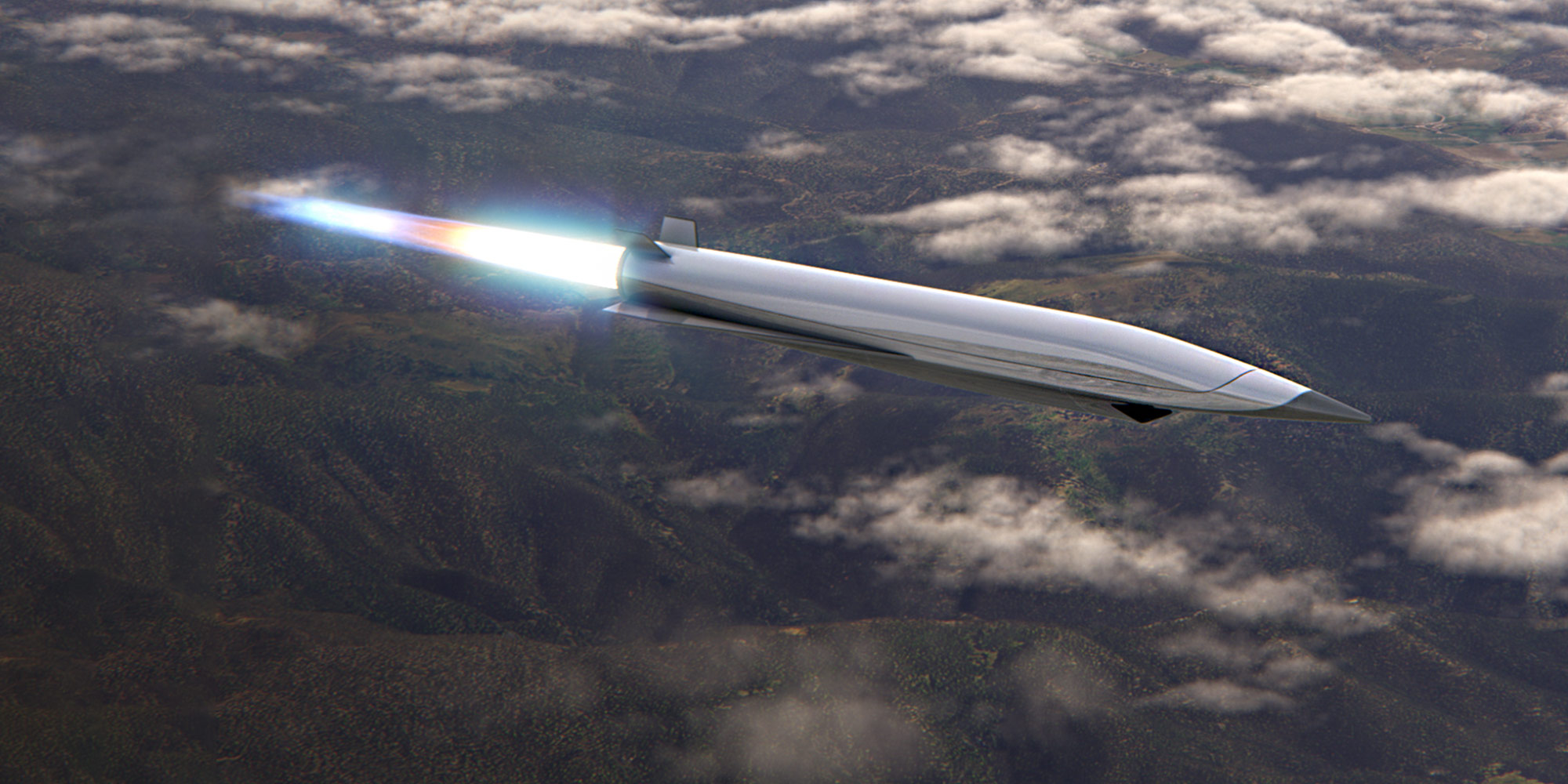

After earning his bachelor’s in mechanical engineering in spring of 2020, Ben was hired by Northrop Grumman. He initially joined the Pathways Program of engineering “rotations” for a variety of experience but left to pursue the position at Elkton. He’s had a role in tests of everything from tiny solid rocket motors that make a bomb or other munition spin after dropping from a plane to tests involving innovative motors for hypersonic cruise missiles.

“Any successful test is a huge win, a great day,” Ben said. “A lot of the happiness, for something like the hypersonic cruise missile motor, is knowing it took hundreds of people to get it there. When you see it light off, and you’re watching the thrust data coming in, and you're hearing and feeling the motor shake the control room, it really is a powerful feeling.”

Matt Wolfe knows that feeling well. He is a Northrop Grumman Technical Fellow and electrical engineer at the hypersonics test laboratory in Ronkonkoma, New York. He joined the company in 2018 and now leads the Performance Enterprise Systems team, which works across disciplines to introduce new technologies that increase the pace of testing.

“Our number one product is data,” Matt said. “We're upgrading instruments and digitally transforming ways we manage and share information. We’re developing digital tools that allow us to track things better and integrate them into our systems and databases more efficiently.”

And they’ve started their own nitrogen farm. Nitrogen, an inert gas, is used to safely pressurize liquid fuels, purge piping and systems of combustible liquids and gases, and rapidly quench combustion to end certain tests. Rocket engine testing involves a lot of nitrogen and issues with deliveries of the gas can cause delays. So, Northrop Grumman invested in equipment for the Ronkonkoma facility to harvest their own nitrogen from the air.

“We're pouring a lot of time and energy into building for the future and making sure that the site can sustain itself,” Matt said. “We're making ourselves more marketable for the customers who want to come in here. We can run longer duration tests, or we can turn around and test more frequently. That’s really important.”

Need for Speed

In addition to being propulsion test colleagues, Ben and Matt are part of Northrop Grumman’s “Mentoring the Technical Professional” program. Matt has been Ben’s mentor for the past year.

“I was drawn to the program by the opportunity to learn from the best in the business,” Ben said.

They both feel the need for speed, a sense of urgency to increase the pace of testing, development and delivery of rocket motors that help keep our country and allies safer.

“You feel good knowing your work is going toward something good, that we are augmenting our defense capabilities,” Ben said. “We are protecting our folks out on the front lines, and our allies in need. It truly is meaningful. It brings a lot of joy to know that I have a career where, yeah, I can have fun and fire up rocket motors, but it's making a difference.”

Matt knows that feeling, too.

“Even with a rocket motor bolted to a test rig, you can feel the thrust of the engine, and you know that's something a lot bigger than all those people in that room, that it’s them and a larger team coming together to accomplish that goal,” Matt said. “I think that's the best thing, for me, at the end of the day. You all succeed as a team, you feel the power and you realize this is going to be something that affects you and the whole country, because there’s so much at stake here.”

Life at Northrop Grumman

Your work at Northrop Grumman makes a difference. Whether you want to design next-generation aircraft, harness digital technologies or build spacecraft that will return humanity to the moon, you’ll contribute to technology that’s transforming the world. Check out our career opportunities to see how you can help define possible.