How did you find your way to Northrop Grumman?

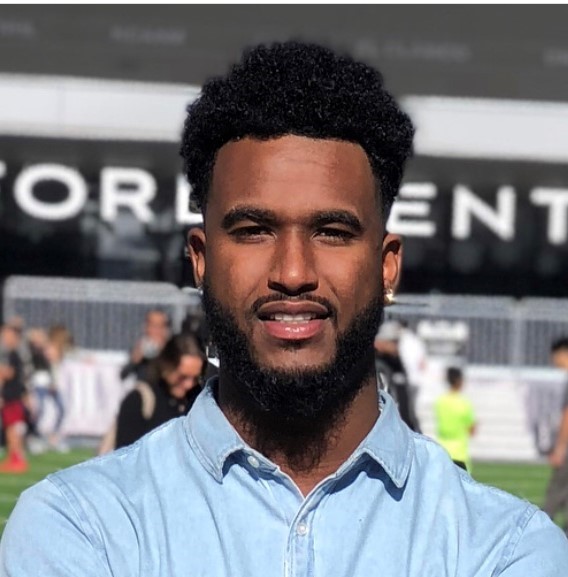

I attended a Northrop Grumman job fair in Huntsville, Alabama, where I met an Aeronautics representative who works in Clearfield, Utah. After having a conversation about composite materials he then encouraged me to apply for a Quality Engineering position, and scheduled an interview for the following day.

What role do you play in the company?

I am the lead quality engineer with Quality Control Material Review (QCMR) authority for the Atlas V program, and the Space Launch Systems program. My job has many functions that revolve around the Material Review Board. I am responsible for submitting nonconforming hardware to the customer, assembling rapid response teams to determine root cause of the defects, and assign corrective actions to prevent reoccurrences. Further, responsibilities include pedigree reviews and audits, which is a thorough inspection of records that is usually conducted by Defense Contract Management Agency.

Can you share a time where you have experienced a defining moment at Northrop Grumman?

At Northrop Grumman, every day is an opportunity to better myself as a quality engineer in the Aerospace industry. A defining moment for me was when I received my first pedigree project. At the time, I had just started my career at Northrop Grumman and had very little composite experience. This project was one of the biggest challenges I’ve faced to date. While the task was difficult, I was able to learn a tremendous amount of information about the Atlas program. I learned how to look through the specifications and processes for specific answers and view the hardware from an auditor’s perspective. This was a defining moment for me because it allowed me to be more confident when explaining deviations in the process to a customer.

How does Northrop Grumman help you to pursue your passions?

As a child, I developed an early passion for understanding complex systems like cars. This passion came to fruition and exceeded my vision for my career path when Northrop Grumman presented me with an employment opportunity. The company’s missions and values have helped me to develop my abilities as an engineer, to build a stronger work ethic, and to cultivate my character as a person. Northrop Grumman provides me with unlimited space and opportunities to foster my childhood passion. My many roles in large structure programs has not only enhanced my professional development as a young man, but has also facilitated a space where my imagination can become my reality every day.

How have you seen the intersection of science, technology and engineering come into play at work?

The facility where I work utilizes an Automated Ultrasonic Inspection System to inspect the internal handiwork of our parts. This system incorporates the use of modern technology robotics, as well as the science behind ultrasonic principles and water, to diagnose unseen defects by the naked eye in our locally engineered products.

How are you exploring the limits of possible at Northrop Grumman?

I have been given the opportunity to learn a state of the art new fiber placement system, the Dockable Gantry System, which combines Automated tape-laying (ATL) and Automated Fiber Placement (AFP) in one machine. The gantry-based unit’s ATL head handles the large, noncomplex surfaces, and then — on the same mold — the machine’s control system can switch, automatically, to an AFP head for narrow, more complex and/or highly contoured surfaces. The head-to-head transition takes less than 2 minutes. For that reason, the system is expected to optimize material deposition rates and increase manufacturing flexibility.