We’ve long been taught that electricity and water don’t mix, but in the real world, they run alongside each other all the time. A team of Northrop Grumman engineers set out to create a safe, reliable and affordable way to connect electric currents in a wet or corrosive environment and keep the power surging. The results are no less than shocking.

A duo of Northrop Grumman engineers have invented a revolutionary way to connect electric currents underwater and keep the power surging.

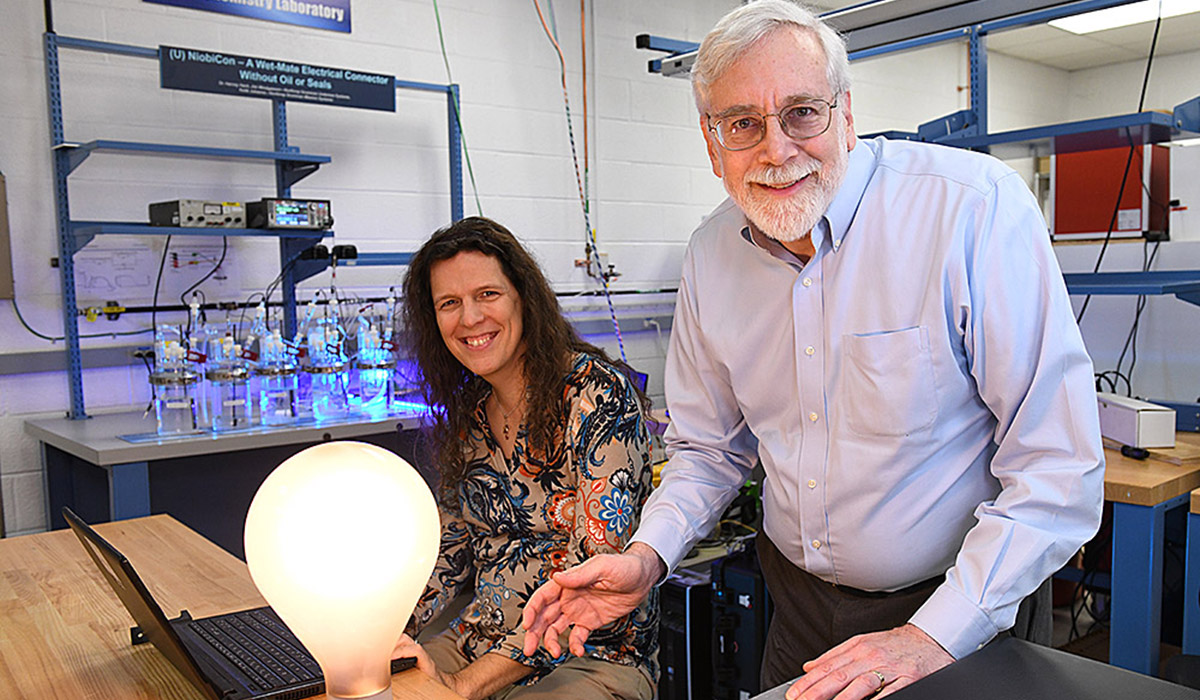

Systems Engineer Jim Windgassen and Northrop Grumman Fellow Harvey Hack were each working on connector technology for different reasons but with the same goal — to extend the relatively inefficient battery recharging of unmanned underwater vehicles while submerged. Windgassen had been taking a different but related approach to the underwater connector problem when he learned that Hack used a metal called niobium for its corrosion resistance. This sparked Windgassen to think about how to apply fundamental principles of tantalum capacitors to make underwater connectors. Niobium and tantalum are similar metals, and it made Windgassen consider how a tantalum capacitor works in the first place, thus becoming the genesis of NiobiCon™.

What Is NiobiCon™?

NiobiCon™ is a revolutionary self-insulating wet-mate electrical connector that can be mated and de-mated while fully exposed to water — a first of its kind. Contacts will not corrode, and electronics will not short out. This new connector technology has the potential to be less expensive, smaller, lighter, more reliable and safer than current wet-mate connectors. Typically, underwater connectors between electricity and water attempt to exclude water from their contacts by using expensive, less reliable rubber seals, oil or moving parts. NiobiCon™ inverts this paradigm and can be used while submerged or anywhere there is a wet, corrosive environment, such as in chemical processing plants, agriculture, automotive applications and undersea operations. While other connectors try to fight the sea, NiobiCon™ works in harmony with it.

Diverse Backgrounds and Collaboration Were Essential for Success

Collaboration with cross-functional teams was essential for the development of NiobiCon™. Initially, a team of three worked on the proof of concept: the two inventors and a technician to construct the test device. Their team eventually grew as they developed the design and more people were invited to lend their skills in finite element analysis, intellectual property (IP) licensing, business development and funding.

“Without this large group of people, the concept would not be developed to this point,” says Hack. “Jim [Windgassen] is an electrical engineer with a strong mechanical background, while I’m a corrosion electrochemist and metallurgist. It is the combination of these two diverse backgrounds that resulted in the concept being thought of. Also, involvement of Keith [Johanns] as the IP licensing manager has helped to get the first commercial connector design developed and has gotten licensing agreements in place. Jim is excellent at sales, Keith is excellent at licensing promotion, and I do the electrochemistry to develop the technical details.”

Northrop Grumman Crowdsourcing Platform Allows Employees to Innovate

Northrop Grumman promotes innovation in its employees through its SPARK program, a company-wide crowdsourcing platform for employees to propose new, innovative ideas and collaborate with colleagues from across the enterprise. By allowing Hack and Windgassen the freedom and resources to develop their unique concept, what began as a SPARK project became a unique solution to combine electricity and water for which two U.S. patents have since been granted. The first connectors could be in the marketplace as soon as mid-2019.

“It is immensely satisfying to see this initial concept generate so much interest, and now to see us on the verge of getting the first licensing agreement,” Hack says. “In addition, the interest from potential users as we display this technology is incredible, with many people becoming so excited about the concept that they start to tell us about potential use scenarios that we may not have envisioned ourselves.”

Northrop Grumman employees collaborate across the enterprise and around the world in areas of physics, engineering, manufacturing, business management and more. Does that sound appealing to you? Search our open positions and apply for a job that’s the right challenge for your skills.

Life at Northrop Grumman: Recent Stories

Shape your career journey with diverse roles and experiences that expand your expertise, feed your curiosity, and fuel your passion.

Life at Northrop Grumman: Archived Stories

It takes every one of us to make the impossible a reality. See what life is like at Northrop Grumman.