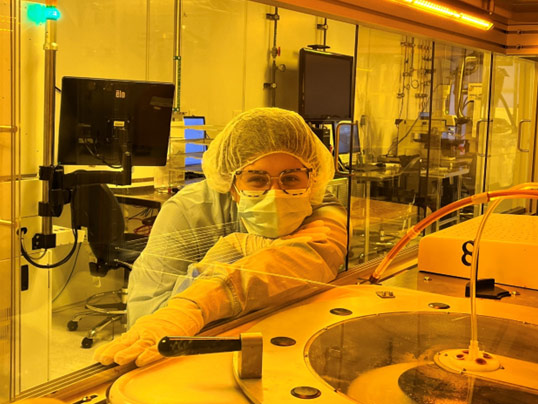

Every day, microelectronics employees don the bunny suit before they enter the cleanroom.

The Process for Precision

How One Engineer Transformed Semiconductor Chip Validation Through Standardization and Collaboration

Summary

Dr. Mindy Liu, a senior staff engineer at Northrop Grumman’s Advanced Technology Lab, identified inefficiencies in the chip-validation process and led a collaborative effort to create a standardized, scalable test architecture. With support from mentors, colleagues, and leadership, she transformed a year-long validation bottleneck into a more efficient, accurate, and reusable system now used by nearly 60 programs. Her story highlights how strong process, teamwork, and perseverance drive innovation and operational excellence.

Key Takeaways

Standardized processes reduce bottlenecks and improve efficiency, accuracy, and scalability.

- Standardizing processes can dramatically improve efficiency, accuracy, and scalability—turning critical bottlenecks into streamlined workflows.

- Collaboration, mentorship, and a supportive culture empower engineers to innovate, lead change, and deliver solutions that strengthen mission-critical capabilities.

By Cassie Mann and Rachael Tiehel

The secret to precision, productivity and profitability? Process.

At a company like Northrop Grumman, process isn’t just important for manufacturing – it’s paramount. Dr. Mindy Liu heard her assignment loud and clear when she joined the Northrop Grumman Microelectronics Center and started diving deep into our processes.

“I saw what existed and took a hard look at how we can make it better,” Mindy said.

Mindy, a senior staff engineer for microelectronic semiconductors, works out of our Advanced Technology Lab (ATL) in Linthicum, Maryland. She joined Northrop Grumman in 2015 with an extensive background in telecommunications, holding a variety of roles – everything from staff scientist to hardware engineer to test engineer.

Mindy recognized that in our organization, microelectronics plays a crucial role in modern battlefields by increasing performance and improving efficiency. This fueled her commitment to her craft and led to an opportunity to revamp timely internal processes.

“I found myself asking how I can take a small idea, turn it into a larger spark, and then create a process that is impactful not only to our programs and benefits our military customer in the end,” Mindy shared.

Tackling a New Challenge

In 2020, Mindy took on a new role in the Northrop Grumman Microelectronics Center, where she gained exposure into challenges with chip validation.

“We produce a lot of complicated and advanced chips, which was leading to a timely validation process. We were doing a lot of unique tests to validate the chip functionalities. This was causing a bottleneck because new engineers required training on these processes,” Mindy said. “My thought was that these tests shouldn’t be taking so long – some up to a year - only to find a problem that we couldn’t solve. I was determined to find a solution.”.

She credits her confidence in her approach to her mentor, Pete Stenger, a consulting engineer who she had connected with through Northrop Grumman’s Mentoring the Technical Professional program.

“Pete told me from the beginning that he believed in what I was doing, and that I needed to be strong as I navigated the path forward and looked for support. This really motivated me to reach out to different people.”

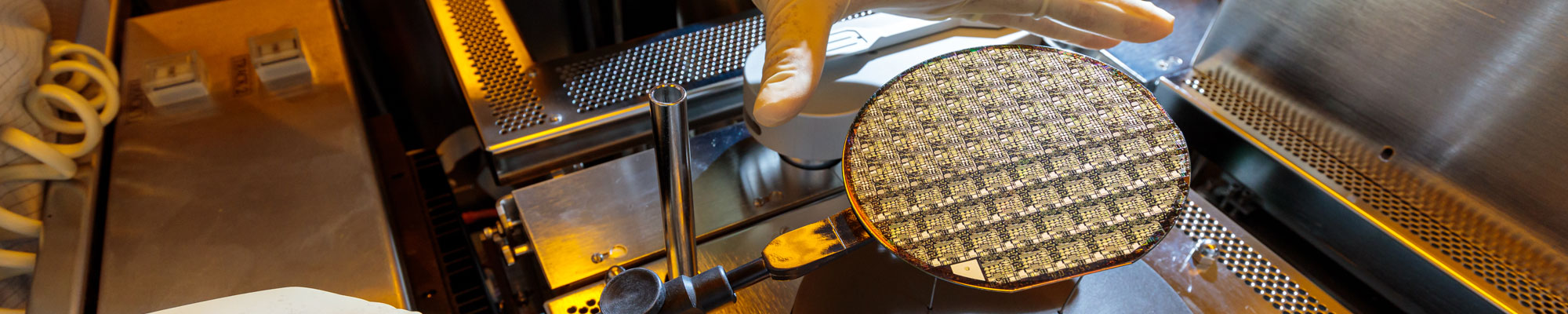

In the end, these conversations would pay off. With over one hundred hours of work logged for the project, and the support of those around her, Mindy created a new standardized scalable test architecture design and implementation. This is a novel test methodology that validates the design of the chips to allow for proper functionality.

Now, nearly 60 programs at ATL are using her solution for validation. Through a combination of hardware and software improvements, the new validation process ensures a seamless transition of products from wafer to interposer, creating something that is highly scalable and reusable.

“Microelectronics validation is a critical part of chip assembly. With this standardization, we shorten the process while making it more efficient, effective and accurate,” Mindy said. And for critical items like chips, time is not only money, but the core of a system’s ability to come to life.

Doing it with the Best Team

While Mindy might have a strong passion for standardization, her true passion lies with the people she works with at ATL.

“We have the best leadership like Matt Hicks, Gautam Khera, Mike Lee and David Kim. Without my manager Alex Dowindchuk and the test team members who supported me in implementing this solution, it wouldn’t have been possible to do in just three years,” Mindy said.

“I’ve worked at quite a few companies, but I’ve never been anywhere with a culture that is so collaborative. We truly share our ideas. People don’t turn you away, they encourage you to try something new. It’s a culture that is so important for an engineer to thrive. Time and time again, I have had the opportunity to utilize my knowledge to help this company grow.”

Life at Northrop Grumman

Your work at Northrop Grumman makes a difference. Whether you want to design next-generation aircraft, harness digital technologies or build spacecraft that will return humanity to the moon, you’ll contribute to technology that’s transforming the world. Check out our career opportunities to see how you can help define possible.