Nothing Inspires Youth to Reach for the Stars Quite Like a Space Launch

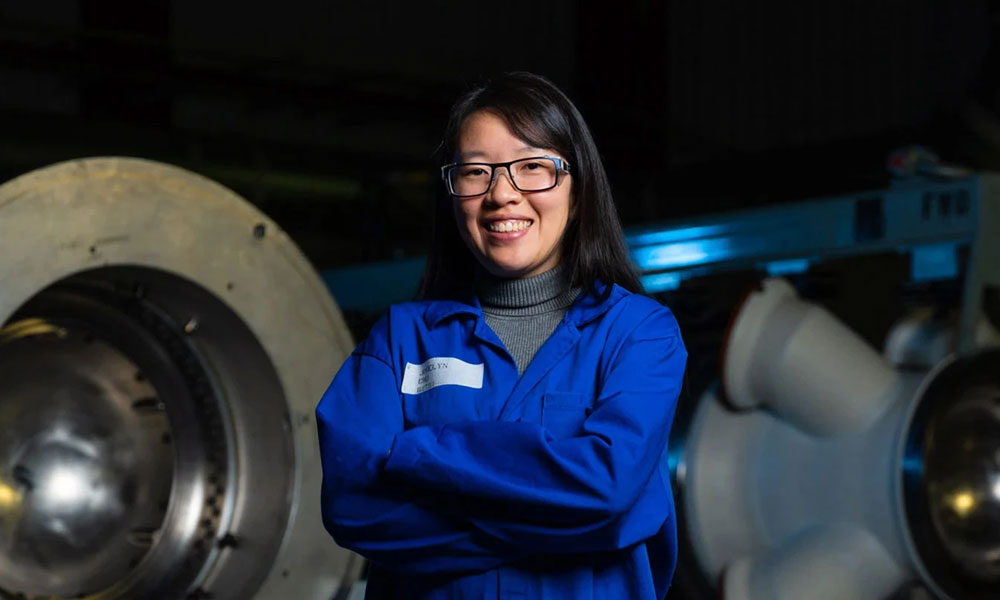

Growing up in Central Florida, manufacturing engineer award winner Stephanie Locks (Hartle), a 27-year-old systems engineer at Northrop Grumman, remembers seeing the rockets go up and feeling the boom of the space shuttle as it went supersonic.

It’s getting that taste for space that started Locks on her pathway to a career in engineering.

Her interest was piqued while accompanying scholars of the Astronaut Scholarship Foundation on a tour of the Kennedy Space Center in Cape Canaveral, Fla. While there, she saw a shuttle up close and watched the fiery launch of a communications satellite.

Cinema also lit a spark. Just as the character James Bond inspired a generation to join the intelligence community, 007’s Quartermaster, or “Q,” continues to lure young talent to the science, technology and engineering professions.

Locks said Q — the character responsible for arming Bond with weird and wonderful “Q Branch” spy gadgets like the X-ray Polaroid, explosive toothpaste, and rocket pack — was a significant influence on her life journey.

“Engineering has always been an interesting field, but Q took it to a new level for me. I mean, how cool would it be to ‘fix up’ a Rolex so that it can shoot out a laser beam?” she explained.

Bringing Quartermaster to Life in an Engineering Career

Now in her third year of the Northrop Grumman Future Technical Leaders rotational program, Locks is the embodiment of Q, bringing the movie screen character to life by applying her skills to real-world missions in defense of the nation and its allies.

Since joining the company in 2017, the graduate of Cornell University and Georgia Institute of Technology (Georgia Tech) has been making waves for all the right reasons, recently receiving the Outstanding Young Manufacturing Engineer Award from the Society of Manufacturing Engineers (SME).

She’s also making radio waves as part of her antenna hardware rotation at the Mission Systems BWI Campus in Linthicum, Maryland. Locks has previously worked in modeling and simulation at Mission Labs in Baltimore and completed a highly successful stint at the Corporate Technology Office in Falls Church, Va.

Though she’s not developing steel-strength floss or laser Rolex watches for secret service agents (at least not yet), Locks loves what she does. Her research into high-technology manufacturing and Industry 4.0 is already helping Northrop Grumman transition to the future.

Leading the Fourth Industrial Revolution

A list of 10 questions Locks developed at the Corporate Technology Office is helping leaders in manufacturing operations identify how to move their assembly lines into the fourth industrial revolution: the automation and networking of tools in a secure environment through the “industrial internet of things” for precision manufacturing. That formula was influential enough to be published by the Society of Automotive Engineers in a book by Northrop Grumman Aerospace Systems technical fellow George “Nick” Bullen, titled “The Future Airplane Factory: Digitally-Optimized Intelligent Airplane Assembly.”

It’s this work, among other achievements, that earned Locks her award by SME. One of 14 recipients for 2019, she received the honor at an awards ceremony at Detroit’s Westin Cadillac Center.

She was nominated by Bullen, who described her as an incredibly talented engineer and leader, writing in a supporting letter that she is “eminently qualified and merits” the award. “Stephanie has built a manufacturing strategy identifying barriers and opportunities for technology development to support Northrop Grumman’s manufacturing groups as they move towards Industry 4.0,” he wrote.

Locks’ nomination was further supported by Professor Thomas Kurfess, who specialized in fluid power and motion control at Georgia Tech, as well as Patrick Antkowiak, Corporate Vice President and Chief Technology Officer at Northrop Grumman.

The Future of Transformational Manufacturing Technologies

Antkowiak said the series of questions Locks developed will be used by Northrop Grumman and similar companies to “critically assess their manufacturing technology migration maturity.”

“The future of transformational manufacturing technologies — such as additive manufacturing, digital ecosystem, digital twins (the digital transformation), nanotechnology, and heterogeneous technology integration — all clearly lead to the potential for disruption and innovation in manufacturing for aerospace and defense,” Antkowiak wrote. “It was clear that we needed fresh new strategies and ideas in order to be fully ready for the potential of transformational manufacturing.”

As Locks describes it, manufacturing is still manufacturing, and at the end of the line, you need a physical product to deliver. But everything’s going digital, she explained, from the design drawings to the data transfer between tools and the incorporation of sensors to detect issues, which all provide an opportunity for machine “self-correction” and optimization. Although some big thinkers are eager to use Industry 4.0 to pass the decision-making to the machines, Locks believes we have a long way to go before the aerospace and defense industry can safely pass on the reins.

Using center fuselage production for the F-35 as an example, she said manufacturing is a highly controlled science and any change to the process could potentially have negative consequences somewhere down the line. You don’t want the machine to have a lightbulb moment and switch processes on its own halfway through production.

“Once a team gets past the data overload, it’s spectacular seeing the type of analysis and decision-making that can be made — that’s why the industrial internet of things is coming to manufacturing,” she said. “It’s not just us, it’s coming to the entire manufacturing industry and needs to be done in a secure way.”

Launching Your Career in Engineering

For young people looking at careers in engineering, Locks said the first one to two years of undergraduate study are the hardest. “You need to get through the hard stuff first, but it will be worth it. Then in the third or fourth year, you don’t need to be worried about finding a job — there are plenty,” she said.

Locks recommended applying for the Future Technical Leaders program at Northrop Grumman — but be prepared to pick up and move around the country. “By the third rotation, you don’t unpack all of your boxes; you figure out what you really need.”

Northrop Grumman provides exciting career opportunities in locations around the globe. Click here to search for systems engineering jobs similar to Stephanie’s, and join us to Define Possible.

Life at Northrop Grumman: Recent Stories

Shape your career journey with diverse roles and experiences that expand your expertise, feed your curiosity, and fuel your passion.

Life at Northrop Grumman: Archived Stories

It takes every one of us to make the impossible a reality. See what life is like at Northrop Grumman.