How the MIMIC Program Catalyzed Northrop Grumman Leadership in Space

By Brooks McKinney, APR

Since the dawn of the space age, Northrop Grumman has partnered with the U.S. government to help define and implement many of the nation's most challenging space missions.

And the electronic payloads that drive those missions — everything from radiometers for NASA remote sensing missions to the satellite electronics that gather imagery and beam it securely around the world in the blink of an eye — trace their origin and performance back to the company's role as a prime contractor for the U.S. Defense Advanced Research Projects Agency (DARPA)'s Microwave and Millimeter Wave Monolithic Integrated Circuits (MIMIC) program.

The MIMIC program and the gallium arsenide (GaAs) chip technology it produced have transformed both the U.S. space industry and consumer wireless communications. They've also helped Northrop Grumman create and solidify a partnership with DARPA that continues to fuel the company's ability to produce critical technology and subsystems for key U.S. space, ground and airborne missions.

MIMIC Program Takes Flight

"Before the mid-1980s, GaAs was strictly a research and development (R&D) technology that existed as single, discrete transistors," explained Aaron Oki, a Northrop Grumman Fellow and manager of Electronics and Sensors Technology unit.

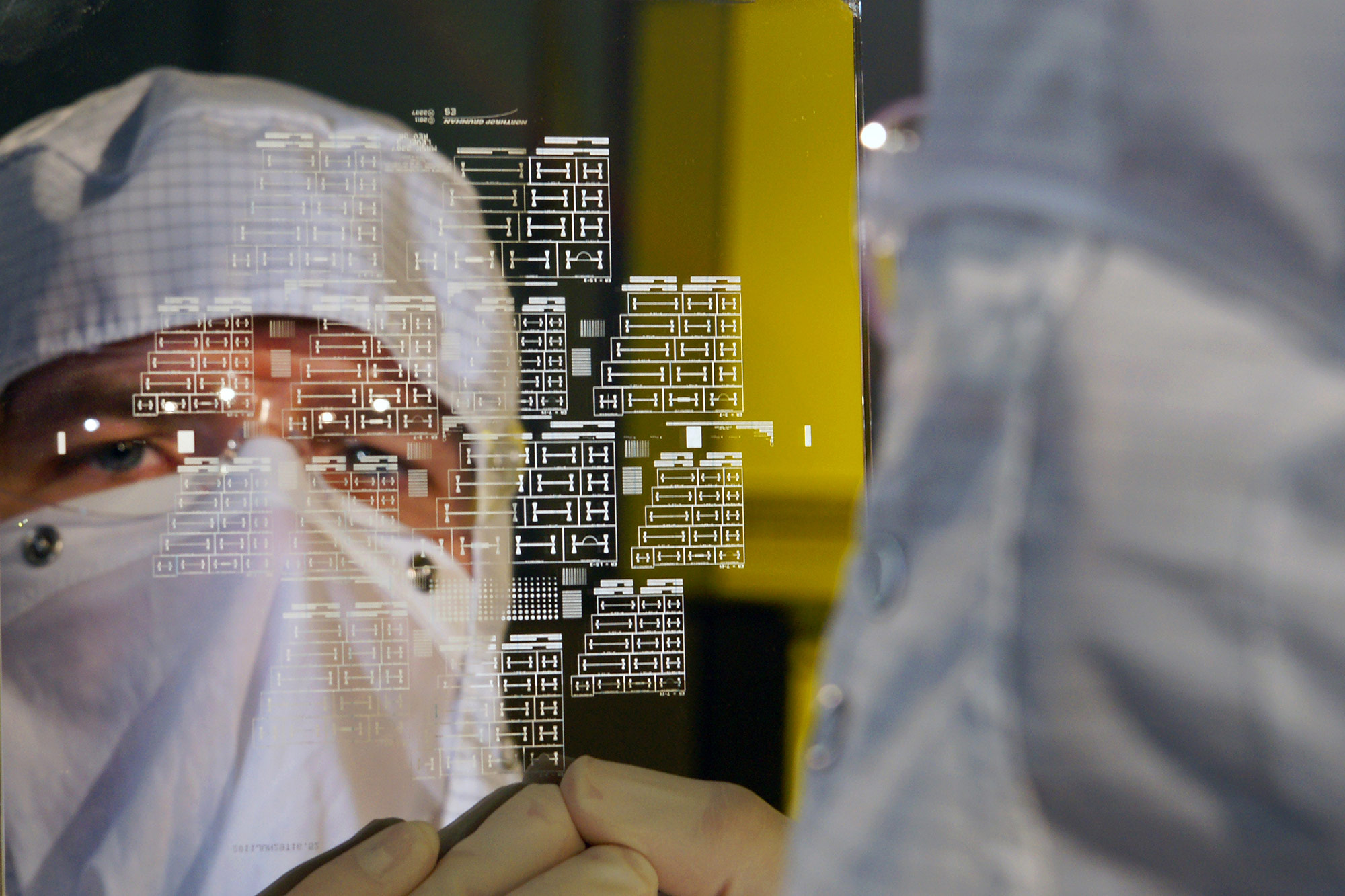

That all changed, however, in 1986, he continued, when DARPA recognized that many new, evolving military systems such as smart munitions and airborne phased array radar were going to need inexpensive, high-performance, high-reliability radio frequency (RF) "front ends" to be fielded cost-effectively. In other words, discrete GaAs components would have to evolve into monolithic integrated circuits that could be produced reliably, in high volume, at an affordable price.

In early 1987, the MIMIC program was born. It focused on making microwave (3-30 GHz) and millimeter wave (30 to 300 GHz) monolithic chips reliable, affordable and widely available for military systems.

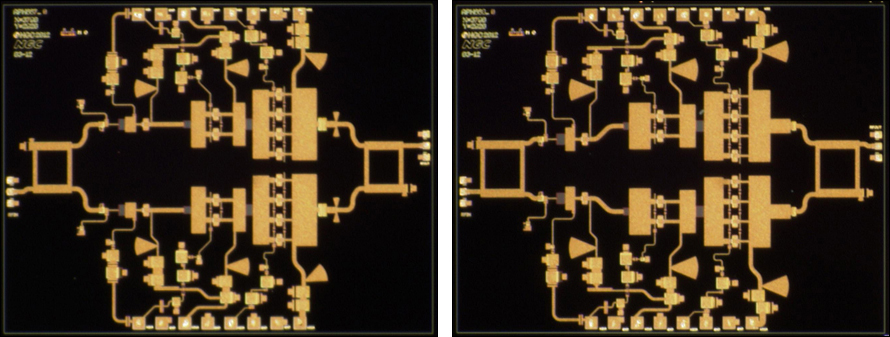

As the leader of one of four MIMIC contractor teams, Northrop Grumman heritage company TRW was expected to mature and demonstrate new high volume, low-cost ways to design, fabricate, test, assemble and package MIMIC chips. But there was a secondary, perhaps more important goal.

"One of the best decisions that DARPA made was to encourage commercialization of MIMIC technology," said Oki. "They recognized that military applications, while critically important for national security, had limited production volumes. Establishing a commercial production capability for MIMIC chips would help keep wafer fabrication processes healthy and chip costs down."

Meeting High Expectations with Very Small Components

GaAs is a III-V type compound semiconductor with several properties that are ideal for aerospace and commercial communications applications.

"GaAs has a very high electron mobility, which allows it to operate at very high frequencies," explained Oki. "High frequency creates higher bandwidth, which allows you to transmit more data per unit time."

In satellite communications, higher frequency means smaller components, smaller antennas and narrower, more secure beamwidths, he added. For an airborne phased array radar, GaAs chips enable arrays containing several hundred transmit/receive modules to fit in the nose of a military jet.

Remarkable Chips Transform Cell Phones

According to Oki, the MIMIC program was foundational to Northrop Grumman's future as a developer and producer of advanced MIMICs.

"The program helped us establish not only our GaAs integrated circuit technology, but also heterostructure technology, such as gallium aluminum arsenide and indium gallium arsenide. By adding more elements, we learned to make devices that exhibited better performance than GaAs alone."

Northrop Grumman also parlayed its GaAs MIMIC pilot line foundry into commercial opportunities. In 1994, it opened a high-volume GaAs production line in Manhattan Beach, Calif. primarily to produce GaAs heterojunction bipolar transistor (HBT) power amplifier (PA) chips developed collaboratively by RF Micro Devices (now Qorvo) and Northrop Grumman for use in wireless handsets.

Those PA chips were remarkable for their high efficiency, small size and minimal leakage current, all of which helped improve cell phone performance, reduce handset costs, and extend battery life and talk time.

"At one point," Oki said, "we were making about two million chips per week for the cell phone market. GaAs technology is still used in more than 90 percent of the world's cell phones."

Ensuring Mission Readiness

The MIMIC program officially ended in 1995, but Northrop Grumman has continued to improve the reliability and manufacturing readiness of GaAs technology to ensure that it exceeds the required mission life of its many applications.

"GaAs technology is helping NASA increase mankind's understanding of the universe, and more importantly, helping defend our nation," Oki emphasized.

Through a combination of internal funding and R&D contracts with DARPA, Northrop Grumman continues to mature not only GaAs, but also other compound semiconductor technologies such as indium phosphide (InP) and gallium nitride (GaN), Oki added.

"There's always a drive towards higher performance and lower size, weight and power," he said.

Today, the company's MIMIC maturation activities focus largely on two of DARPA's primary areas of interest: reducing the time and costs associated with chip design, and maturing a new packaging technique called heterogeneous integration. This new approach allows multiple RF (GaAs, InP, GaN) and digital (silicon) chips to be placed in one package, which improves the performance of spaceborne electronics.

Northrop Grumman no longer produces GaAs chips for wireless handsets, but it continues to provide GaAs foundry services for select commercial markets, including very small aperture terminals (VSAT) used to enable Wi-Fi on commercial aircraft, and backhaul communications, which relay cellular calls from local cell sites to the central network of local communication providers.

Partnering for Innovation

In the end, observed Oki, the company's leadership in space electronics is built largely on the shoulders of DARPA and the agency's vision for the future needs of military and government systems.

"DARPA has always been extremely good at managing innovation," he said. "Their people have the expertise and vision to sense where technology is headed next and to motivate development of that technology long before it's needed for critical applications. We couldn't ask for a better partner.

More Innovation Stories

Read all stories about advanced technology and innovation >>