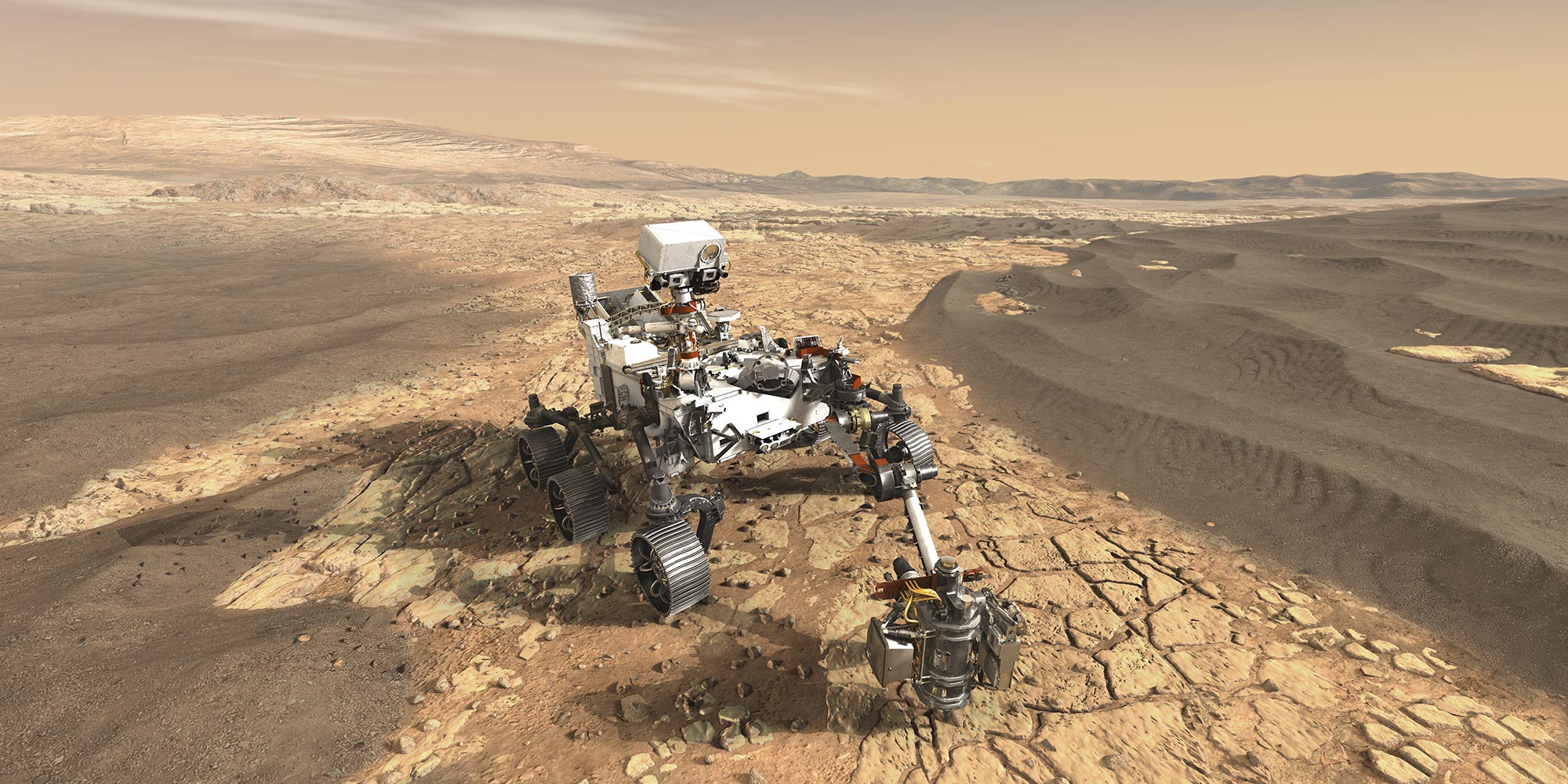

Navigating Mars and Beyond

NASA's 2020 Perseverance Rover gets around with a lot of help from Northrop Grumman's LN-200S IMU.

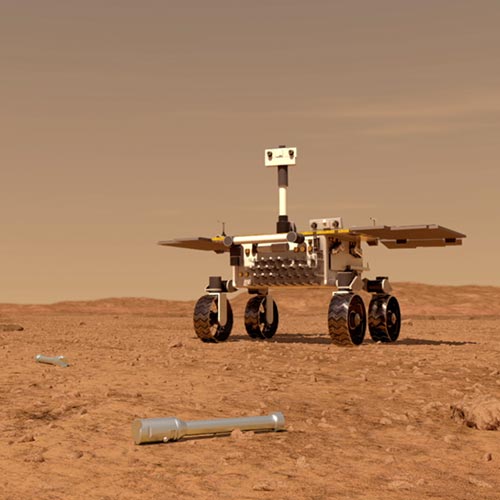

This soup can-sized sensor, part of the company's family of LN-200 IMUs, has been a reliable part of every NASA Mars rover mission since the Spirit and Opportunity rovers began exploring Mars in January 2004. That legacy continues today with Mars rover Curiosity, which remains operational more than eight years after starting its expected two-year mission on Mars in August 2012.

"We like to say we have a 100 percent IMU market share on Mars," said George Pavlath, a Northrop Grumman Fellow considered by many to be the inventor of the LN-200.

Pavlath, who holds a doctorate in applied physics from Stanford University, is an expert in fiber optic gyros. He was the director of engineering for the team that invented the device in the late 1980s for Litton Industries, a heritage Northrop Grumman company.

The LN-200 became the world's first fiber-optic-gyro-based IMU and has been in full-rate production since 1994. Since then, Northrop Grumman has delivered more than 35,000 units to more than 100 customers covering a variety of space, defense and commercial applications.

Accelerating Martian Rover Exploration

"You can think of the LN-200 as a high performance motion sensor," said Bill Harvey, the LN-200 product line manager for Northrop Grumman Navigation Systems Division in Woodland Hills, Calif. "It's filled with three fiber optic gyros and three linear accelerometers that detect rates of angular motion and changes in linear velocity, or acceleration."

According to NASA, Perseverance will use its IMU to help navigate the Martian surface safely as it looks for rocks that contain indicators of previous microbial life, drills core samples from Martian rocks and soil, and tests ways to produce oxygen from the carbon dioxide Martian atmosphere. Key to that navigation will be the IMU's calculation of the rover's attitude, i.e. its orientation about three-axes relative to the Martian surface.

Stabilizing a Changing World

"One of the most common uses of our IMU is image stabilization," said Harvey. "You've probably noticed on the evening news how remarkably stable the images are coming from news helicopters looking down at the ground."

In that application, he explained, the IMU and the camera are attached to a gimbal on the underside of the helicopter. As the IMU detects the rotations and bumps the helicopter is experiencing from air turbulence, it commands the gimbal to move in the opposite direction, which allows the camera to remain pointed in the desired direction.

Defense applications for the LN-200 include radar stabilization (i.e. maintaining the direction of a radar antenna as it propagates its signal), stabilization for optical targeting pods and cameras used to record missile strikes from drones, and guidance systems for torpedoes and air-to-air missiles.

"The LN-200's fiber optic gyro and silicon accelerometers are all solid state, so there's nothing to break. That makes the IMU extremely rugged and extremely reliable."

– George Pavlath

Bringing Precision Down to Earth

The LN-200 is also used widely by oil and gas companies to conduct critical pipeline inspections. Commonly, the IMU is integrated into a device called a "pig" that is pushed through a pipeline looking for weak or damaged portions of the pipeline.

"Starting from a known position on the Earth, the IMU uses its angular rates and changes in velocity to determine its exact position in the pipeline," explained Harvey. "That allows an oil and gas company to start their repair process precisely where the pipeline is damaged rather than digging up a mile of a pipeline to figure out where it's broken."

The IMU can also be used to map geologic features of the Earth, he added.

Delivering "Off the Chart" Reliability

Perhaps the LN-200's most significant attribute, observed Pavlath, is its reliability.

"The LN-200's fiber optic gyro and silicon accelerometers are all solid state, so there's nothing to break," he said. "That makes the IMU extremely rugged and extremely reliable. Once you put it into some sort of vehicle, camera or radar, it will stay there for 20 years without problems."

Meeting Future Expectations

The LN-200 remains the workhorse IMU for many Northrop Grumman customers, but Harvey and his team are continuing to refine it and to develop new models to address more advanced applications.

The LN-200E model, for example, has been in production since 2012. It is the same size and weight as the LN-200 but offers about twice the inertial performance of the LN-200, primarily because of a higher fidelity fiber optic gyro. The company has also demonstrated a new LN-200HP model that is expected to provide about seven times the performance of the original IMU.

Underpinning the LN-200's quarter century of success has been the strong team supporting it.

"The LN-200 is one of those programs that everyone wants to work on," said Harvey. "I can't emphasize enough the strong sense of pride and personal ownership that everyone on this team feels. I'd have to say this is probably the most fun job I've had in all my years in the aerospace business."

Rover Image Credits: NASA/JPL-Caltech

More innovation stories

Click here to read all stories about advanced technology and innovation >>