Space

Northrop Grumman solves the toughest problems in space.

Beyond the Cosmos: The Voyage of NASA’s James Webb Space Telescope

Major Funding Provided by the Northrop Grumman Foundation, Narrated by Michelle Williams, and Premiering in IMAX

With major funding provided by the Northrop Grumman Foundation, in collaboration with IMAX and Oscar-nominated Nathaniel Kahn, “Deep Sky,” is a riveting documentary chronicling the awe-inspiring journey of NASA and Northrop Grumman’s high-stakes odyssey to develop and launch the groundbreaking James Webb Space Telescope. Voiced by Michelle Williams, the film offers unprecedented cosmic visuals and intimate looks at the observatory. Experience the film in IMAX theaters starting today.

Northrop Grumman Honored with Prestigious Collier Trophy for NASA’s James Webb Space Telescope

Kathy Warden, chair, president and chief executive officer, Northrop Grumman accepted the prestigious 2022 Robert J. Collier Trophy at the annual National Aeronautic Association Collier Dinner on behalf of the company for its pioneering work on NASA’s James Webb Space Telescope.

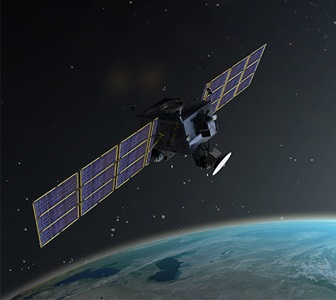

Defining Possible in Space

Right now, Northrop Grumman is pioneering across every sector of space, helping government, civil and commercial customers tackle some of their biggest challenges. Our forward-leaning, pioneering spirit is backed by a legacy of expertise that began at the dawn of the space age.

Our mission expertise in space runs deep, we know our customers well, and our capabilities are unmatched. This is what allows us to provide reliable, agile, and affordable space solutions to solve our customers’ toughest problems.

From defending freedom to advancing human discovery, we are defining what is possible in space every day.

NASA's Artemis I

Northrop Grumman supports NASA’s Artemis program by providing the solid rocket boosters for the NASA Space Launch System and the abort motor and attitude control motor for the Orion spacecraft’s Launch Abort System.

Cosmic Game Changer: Northrop Grumman and NASA’s James Webb Space Telescope

Read this fascinating three-part series on the creation of the James Webb Space Telescope.

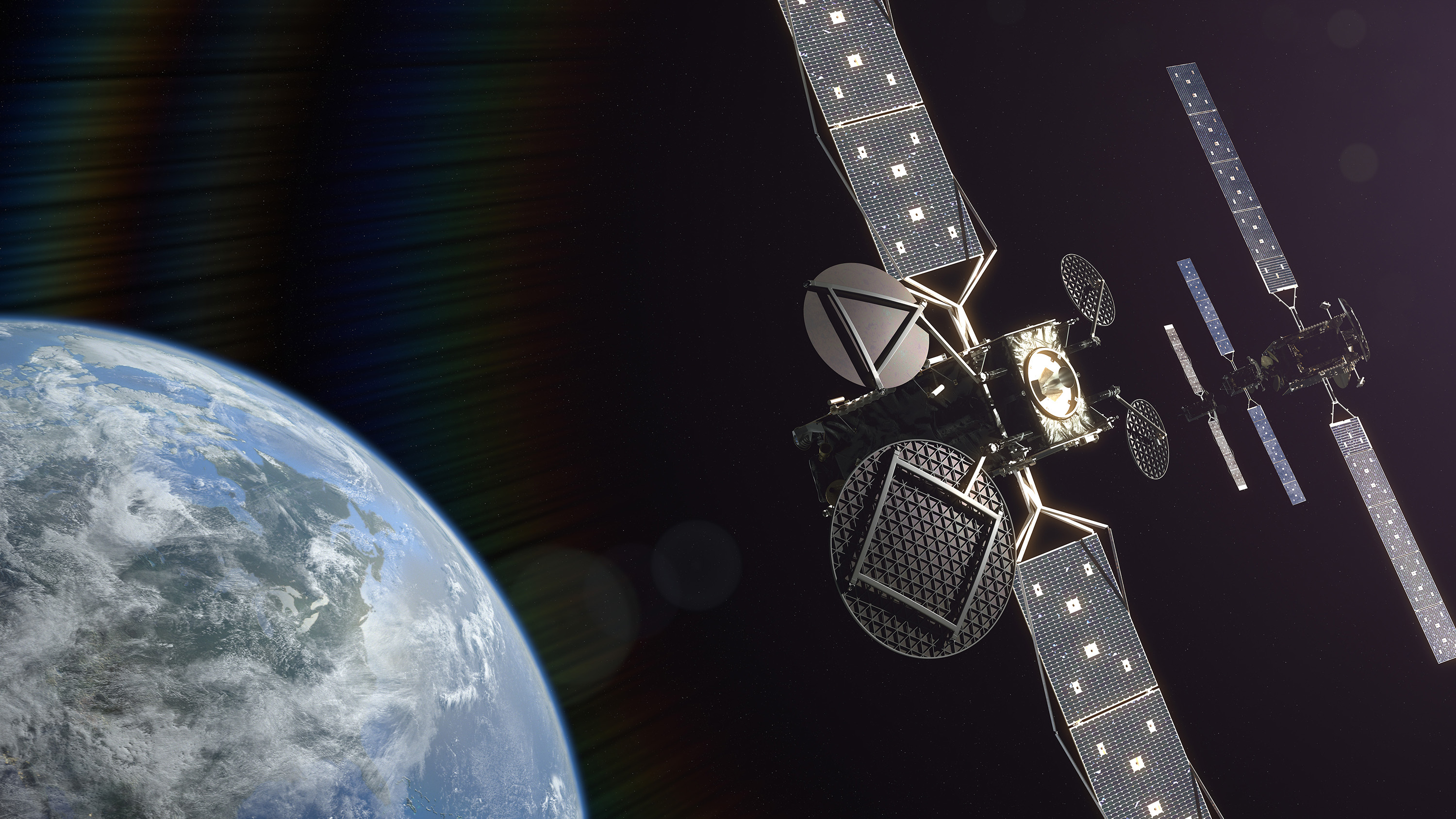

Global Space Security

Northrop Grumman's deep mission expertise gives us a unique perspective to know what it takes to protect the warfighter and preserve freedom, both in space and from space. Our leading-edge technologies and agile practices lead to pioneering breakthroughs that enable our customers to carry out their vital missions to preserve freedom on the ground and in orbit.

All of this is made possible by the industry’s best team. We know the roles we play are integral to our nation’s security and we are committed to solving our customers’ toughest problems, now and for decades to come.

Discovery

Our depth and breadth of mission experience in developing leading-edge space technologies allows us to play vital roles in the quest to answer compelling questions about the origins of our universe, to explore beyond our own planet, and pioneer new technologies.

Our team is passionate about space exploration, science and technology. We have been part of space exploration from the very beginning and we continue to lean forward in defining infinite possibilities for our customers to solve their toughest problems as we build the future of space.

Our Legacy in Space

Building the future of space takes a deep understanding of where we came from. From the dawn of the space age, the companies that are a part of Northrop Grumman have achieved historic accomplishments. The company was instrumental in the development of the nation’s first missile and satellite programs, the achievements of the Apollo moon landings, the development of the Space Shuttle and International Space Station, and many ground-breaking space science missions. We made history in space.

Digital Transformation

Northrop Grumman is harnessing integrated digital technologies to rapidly conceptualize, design, build, and sustain value-driven solutions in Space.

Videos: Innovations in Space

What Northrop Grumman does in Space

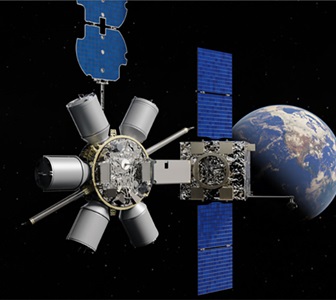

Since the dawn of the space age, Northrop Grumman has put innovative products and ideas into orbit, on the Moon, and beyond – from systems engineering, spacecraft manufacturing, precision sensors, space instrument design, ground stations development, orbiting space platforms and revolutionary launch vehicles.

Technology and Innovation

For some, the word 'impossible' ends discussions. For us, it's a starting point.

Space in the News

Read all about Space in the News.

Northrop Grumman Gifts James Webb Space Telescope Full-Scale Model to the Space Foundation

Northrop Grumman’s Ballistic Missile Target Successfully Launched for Aegis Weapon System Test

Northrop Grumman Next Generation Interceptor Solid Rocket Motor Delivered for First Static Test Fire

Northrop Grumman Completes First BOLE Solid Rocket Motor Segment for NASA’s Space Launch System

Northrop Grumman’s 20th Cargo Resupply Mission Successfully Launches to the International Space Station for NASA

Northrop Grumman Satellite-Refueling Technology Selected as First Preferred Refueling Solution Interface Standard for Space Systems Command (SSC)

Northrop Grumman Completes Essential Tests for Arctic Region Satellite Communications Program

Northrop Grumman Selected to Deliver Nearly 40 More Data Transport Satellites for Space Development Agency’s Next Generation Low-Earth Orbit Constellation of Connectivity

Top banner image: The first anniversary image from NASA’s James Webb Space Telescope is the Rho Ophiuchi cloud complex, the closest star-forming region to Earth. (Photo Credit: NASA)