Five Innovations Made Possible With Carbon Nanotubes

Why we have just scratched the surface of their applications.

By Kelly McSweeney

Carbon isn't exactly a novel material. After all, it's in everything from pencils to diamonds. So, what makes carbon nanotubes (CNTs) so special?

"They have morphological features, or structural features, that account for their extraordinary properties," says Northrop Grumman Fellow Ed Silverman. He continued, “CNTs have the potential to revolutionize the designs and operations for future lighter weight air and space vehicles requiring higher quality intelligent, surveillance, and reconnaissance information.”

"CNT is only about 10% the weight of copper allowing for greater payloads and reduced fuel costs, and for space vehicles, the value of saving a pound can be greater than $40,000."

– Ed Silverman, Northrop Grumman Fellow

Dr. Ed Silverman

Northrop Grumman Fellow

History of a High-Performance Material

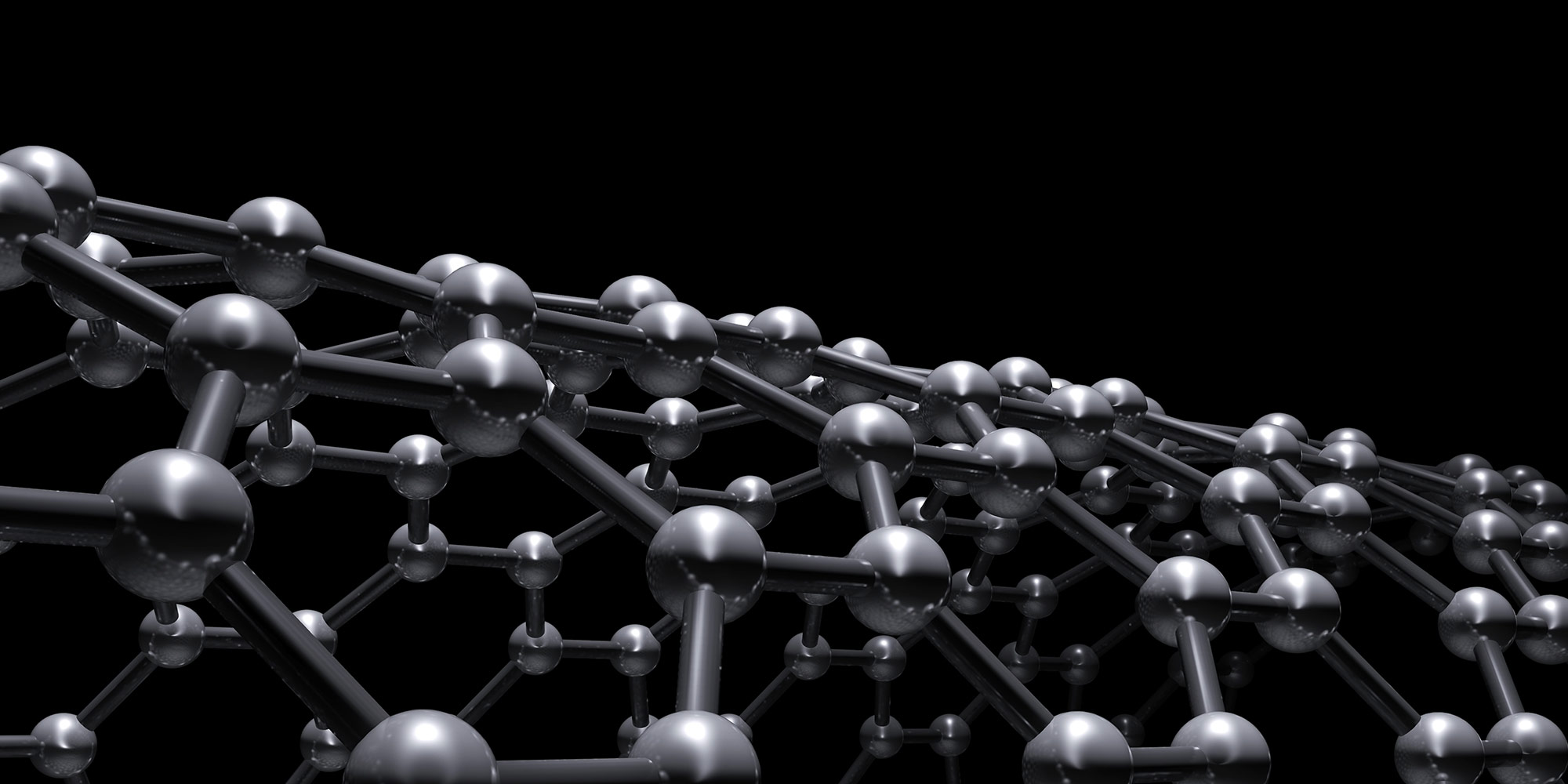

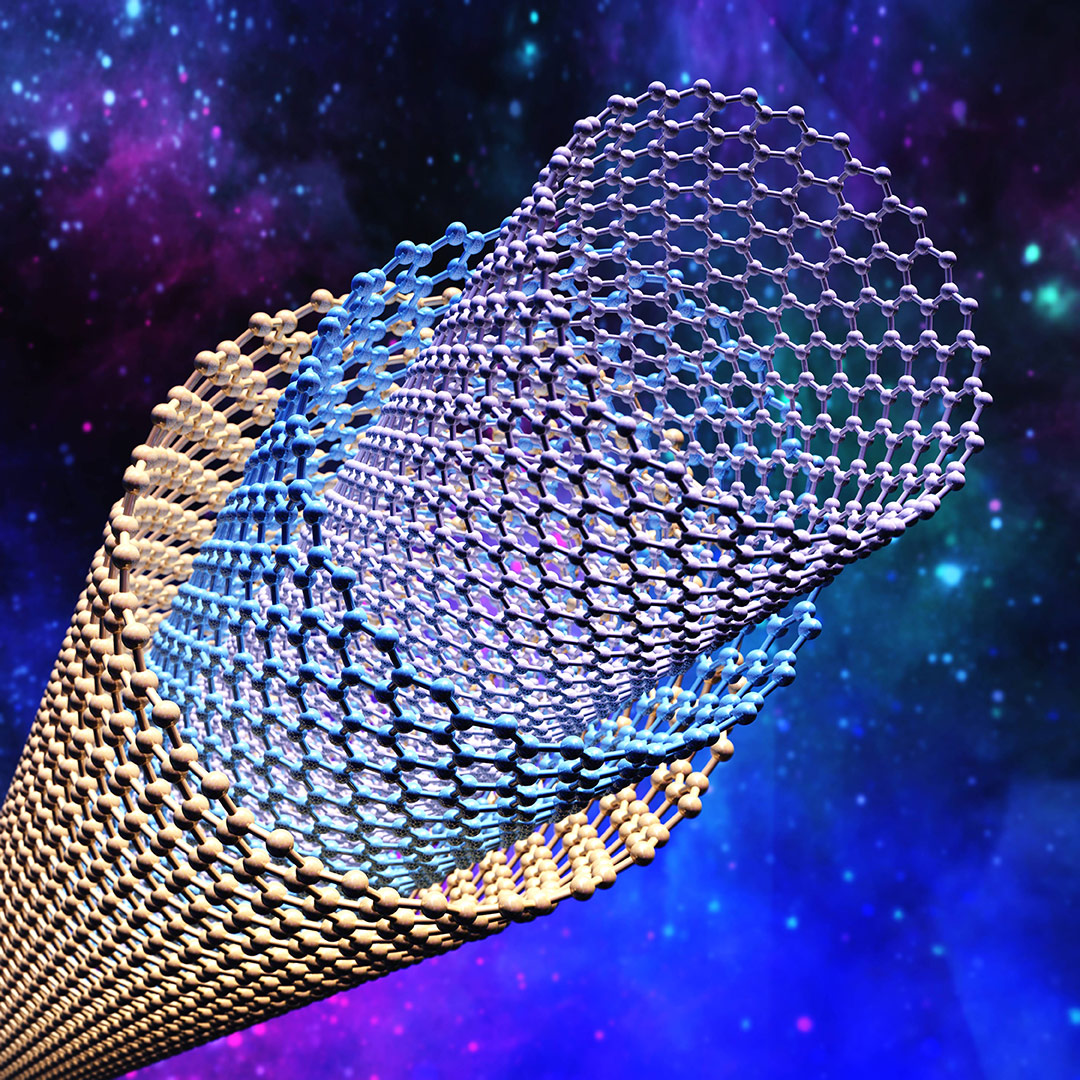

Carbon nanotubes are hollow tubes made of rolled-up graphene sheets (a single layer of carbon atoms) with diameters typically measured in nanometers and length measuring several microns. They also have an incredible aspect ratio, being less than 100 nanometers in diameter while stretching as long as a thousandth of an inch (25,400 nanometers). This really brings "long and skinny" to a whole new (tiny) level.

A researcher named Sumio Iijima first discovered carbon nanotubes back in 1991, NEC notes. After that, the hype built quickly. Researchers around the world suggested that carbon nanotubes could be used to replace cathode-ray tube displays or even to build a giant elevator to space. But these were theoretical applications, and eager early manufacturers were soon stuck with a CNT surplus as real-world applications stalled.

Then, in 2012, manufacturers developed more practical ways to bundle CNTs together and they became a real option for solving problems.

Northrop Grumman’s engineers were on board with manufacturing applications and developments as well. They quickly moved from thinking of CNTs as a laboratory curiosity to a game-changing material and set out to find its application fields in the area of lighter weight cables and lower-cost thermal gaskets. They've proven particularly useful in aerospace because "they're conductive, lightweight, flexible and tough," Silverman says.

Because of their small size, Silverman explained, the nanotubes have unique morphological characteristics like large surface area and high aspect ratios. These characteristics, when coupled with lighter weight promises to achieve a synergistic (not parasitic) combination of multifunctional properties. These diverse properties include thermal and electrical conductivities, radiation/EMI shielding, electrostatic discharge mitigation, damping, straylight absorption, electronics miniaturization, and energy storage and power generation.

Today's Transformative Nanotube Technology

With this combination of features, CNTs have leveled up innovations in both space and defense. Silverman describes five recent applications where CNTs are already providing and promise to be game changer technologies.

Five Innovations Made Possible With Carbon Nanotubes

1. Lighter-Weight Coax Cables for Space Vehicles

Spacecraft, aircraft, and missiles use a large amount of coaxial cables, which can really weigh them down. Anytime you're trying to make something fly, reducing weight can make a big difference in the performance and overall cost. Silverman explains that even though traditional cables are made from inexpensive copper, CNTs are so effective in reducing weight that they will save costs in the operation of space vehicles.

"CNT is only about 10% the weight of copper allowing for greater payloads and reduced fuel costs," he says, "and for space vehicles, the value of saving a pound can be greater than $40,000."

2. Thermal Gaskets for Cooling Electronics

A common challenge in aerospace engineering is transferring heat away from electronics to avoid overheating. One way to enhance heat transfer is to have many contact points in a gasket that connect the heat dissipating chips to the heat sink.

"Within a square inch of a pad of nanometer diameter carbon nanotubes, you're going to have greater than 400,000 contact points that help transfer heat," Silverman points out. In addition, the CNT gasket does not need an adhesive for bonding allowing for easy removability which saves labor costs.

3. Stray Light Absorption

When you want to observe something in space, you need to block out the stray light from the sun so you can get a good image of the object you're observing. Telescopes and star trackers are usually painted or coated with a black material to absorb the stray light.

Carbon nanotubes grow in a forest-like structural morphology called a vertical array, with the long, narrow tubes standing tall in rows. As Silverman explains, "The spaces in between the 'trees' have a trapping mechanism that can trap light." This is a major win.

4. Radiation Shields

Radiation protection is critical in space, where protons, electrons and cosmic rays can harm people and electronics. The electronics in satellites are typically encased in aluminum shields that provide a physical barrier for radiation — but there's always room for improvement.

Silverman and his colleagues experimented with various nanomaterials and developed a new composite material. Starting with a lightweight polymer base, they added CNT and nano-tungsten particles to create a lighter shield. Silverman explains that nano-tungsten particles works well because they are exceedingly small and can be used to form thin, highly efficient electron-shielding multilayer composite films, while CNTs have a high concentration of hydrogen, which is especially effective at blocking protons.

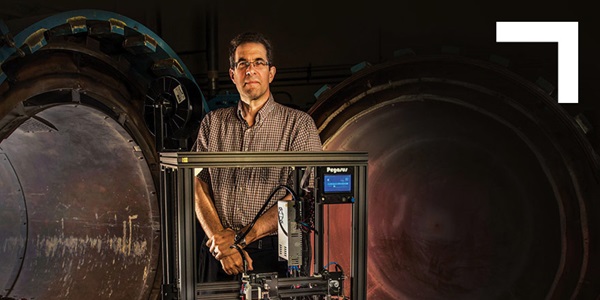

5. 3D-Printing Composite Material

Another huge challenge in space is electrostatic discharge (ESD). Any item that is being designed for space has to be ESD-safe. This is usually achieved by using conductive materials, such as silver, to spread out any charges that would otherwise build up and potentially cause damage. Due to their large aspect ratio, carbon nanotubes are able to form an electrical network at a low concentration which facilitates the 3D printing of composite parts. Therefore, even if CNTs make up only 2% of the weight of a composite, they can make a plastic material conductive enough to be used in space.

"In order to get my electrical connection, I need only a low concentration of CNTs to get the same electrical conductivity as carbon fibers or even silver, which require a significant higher particle concentration," says Silverman.

More innovation stories

Read all stories about advanced technology and innovation >>