Future Vertical Lift

The Agile-Built Helicopter for the Modern Military

By Albert McKeon

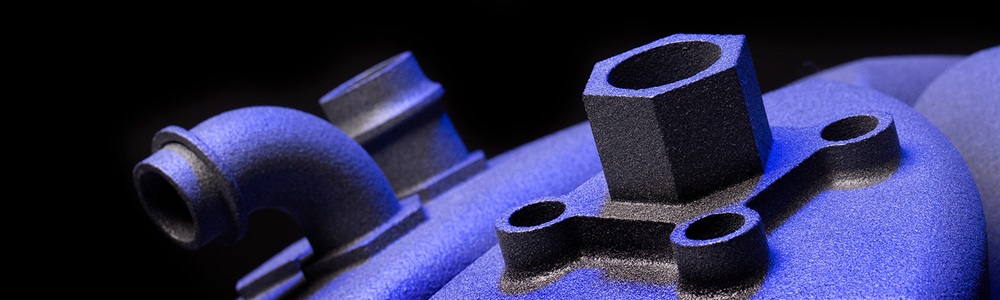

Does a military helicopter have to be the sum of its many disparate parts — blades, tail rotors, navigational equipment, sensors, a fuel system, landing gear and more? The current list of individual components is nearly as long as the heights these vehicles ascend.

But as national defense and the technology behind it change at a rapid pace, it's become clear that a military aircraft must be a cohesive product. Wanting to stay ahead of that curve, the Army is modernizing and streamlining the production of its helicopters and making them more responsive to changes on the battlefield.

With Future Vertical Lift (FVL), a fittingly named Defense Department initiative, the Army aims to create a digital backbone for rotorcraft so that the avionics and self-protection systems of helicopters work in an integrated manner. This integration will allow for rapid upgrades as the operational environment and technology changes. Supporting this generational change, Northrop Grumman, in partnership with the Army, has established a new paradigm for vertical lift mission system agility and relevance.

"These systems are not Lego blocks," said Jim Conroy, vice president of navigation, targeting and survivability at Northrop Grumman. "They're very complicated pieces that must interlock, and interfaces need to interact with one another."

Digital Evolution Taking Flight

FVL amounts to a wholesale digital transformation of an integral part of the Army's fleet, even while acknowledging the evolution since the military helicopter’s debut in World War II. The process incorporates new design and production techniques. It marries hardware and software to move past gated components and instead creates an open and flexible infrastructure.

A critical enabler is being produced by Northrop Grumman; the open systems approach is the Army-managed architecture flying on the UH-60V. This groundbreaking open, safe and secure capability not only digitizes the entire platform, it future proofs it and allows the Army to rapidly iterate capabilities as required by the mission. This state-of-the-art-architecture, the first to implement multi-core processing on an Instrument Flight Rules (IFR)-certified Army helicopter, is undergoing final certification.

"It shows the agility and speed of production through FVL, by rapidly integrating capabilities that would normally take months, even years," said Conroy. "Instead, we're able to do it in weeks."

Developing an Agile Helicopter

The Defense Department started FVL as a way to make the Army's aviation fleet faster, more lethal and more survivable. Military threats are constantly evolving — not just because of geography and the strength of combatants, but also because advances in technology dictate how battles are fought and missions are completed. Behind the scenes, FVL can achieve those goals because of the advanced technology and digitized platform, according to Northrop Grumman Director Brendan Kelly.

Nearly eight decades ago, the world's first mass-produced helicopter, the R-4, was also the first helicopter to be used by the U.S. military. After serving largely as a support vehicle in the Korean War, the role of the helicopter expanded in the Vietnam War, with the Army using it for large-scale troop movements and fighting — a new warfare concept known as "air mobility," according to Century of Flight.

But the military's scope of operations and its technologies have changed considerably since then. Contemporary systems on military aircraft need constant updating to adapt to changing threats and missions. That means while the engine may get replaced just once during a helicopter airframe's service life, the digital avionics need to always evolve and always work in tandem with the rest of the aircraft.

Open Systems Architecture Opens the Door to Diverse Suppliers

That's where Northrop Grumman's modular open systems approach (MOSA) architecture comes in, Kelly said. MOSA gives customers such as the Army the freedom to choose the hardware and software that best meets their needs, regardless of manufacturer. This allows the Army to integrate Northrop Grumman's solutions with other manufacturers' systems so that a helicopter, for instance, can be built with agility and lasting relevance.

The new approach accommodates a more diverse set of suppliers to include smaller companies that have not traditionally contributed to DoD platforms but are on the cutting edge of innovation.

"It stimulates constant competition and collaboration, bringing in the ideas of smaller companies that don't have the necessary pedigree or infrastructure and combining those ideas with the established platform of Northrop Grumman and its partnership with the Army — ensuring this agility helps with innovation," Kelly said. "What the Army is trying to do is Herculean: modernize by 2028. It's going to take a lot of time and resources to accomplish that. But FVL will integrate systems to make them greater than the sum of their parts, and it will do so in an open manner."

To achieve these lofty goals, you need expertise to understand how all the pieces come together, Conroy added, “These are very complex systems; it's not just power consumption. It's interacting electronically, thermally — all of those nuances."

Transformation for Future Pilots

Northrop Grumman is drawing on MOSA to propose mission systems for two new Army helicopters: Future Long-Range Assault Aircraft (FLRAA) and Future Attack Reconnaissance Aircraft (FARA).

FLRAA is meant to provide power projection, according to the U.S. Army — essentially increasing the range, speed, mobility and payload capabilities of their helicopters. It's intended to give combat aviation brigades "long-range, high-speed options that are survivable in contested environments," as the Army notes.

FARA is expected to bring "sweeping improvements in lethality, agility, reach, survivability and sustainability to provide capability and flexibility to future commanders," the Army says.

Indeed, much of the idea of Future Vertical Lift and the digital backbone it creates in helicopters is to put the proper tools in the hands of pilots who aren't yet in the military.

"Ultimately, we don't know how the threat environment could change," Conroy said. "There's constant interplay between us and adversaries. We don't know where the future will be, so you need to adapt and be agile to integrate emerging capabilities."

More Innovation Stories

Read all stories about advanced technology and innovation >>