Advances in composite technology are helping the aerospace industry prepare for increased pressure to get new aircraft out the door and into the skies.

Making Super-Small Microelectronics with Superpowers

By: Kelly McSweeney

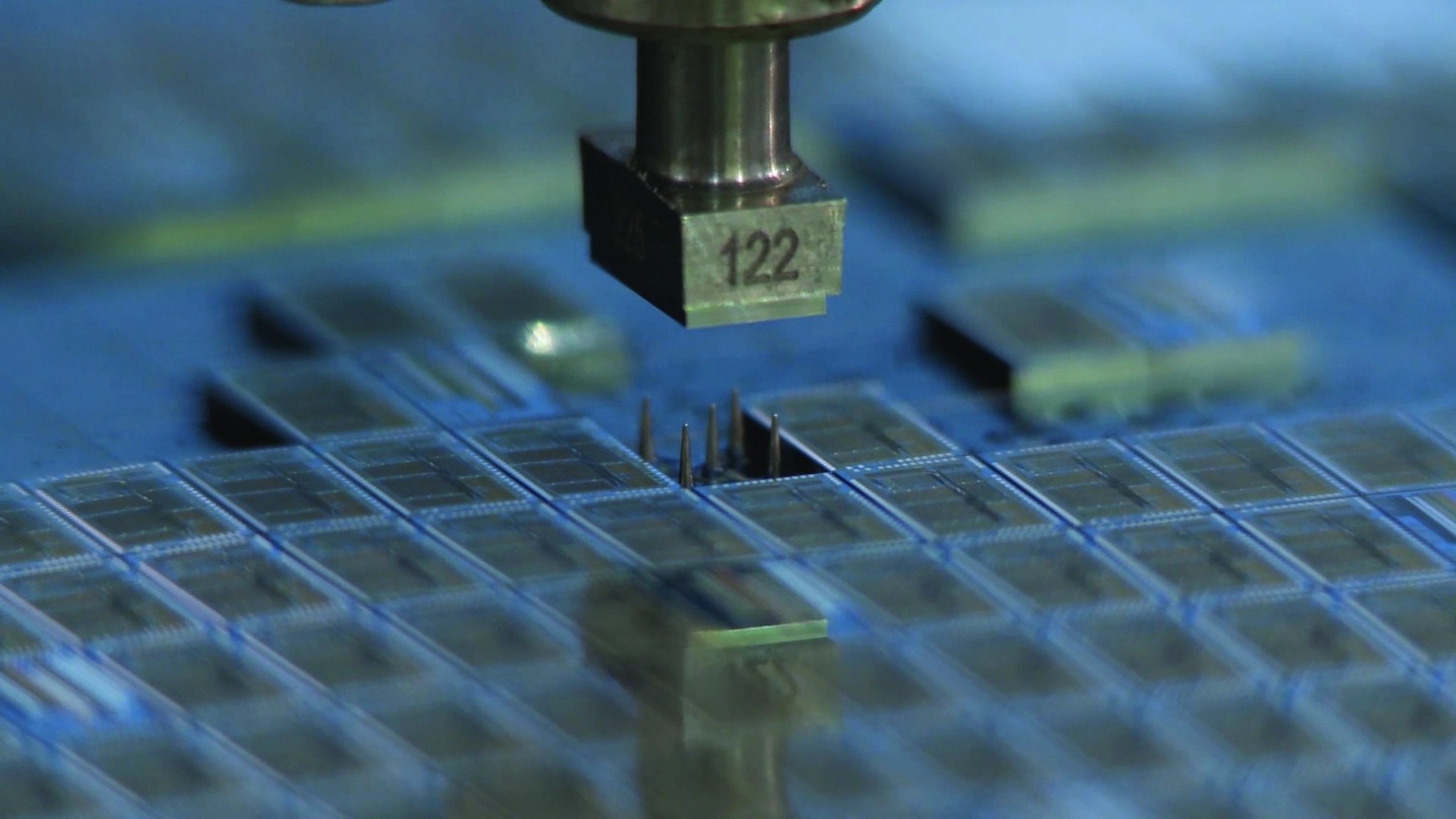

Microelectronics and semiconductors— the tiny components such as transistors, amplifiers, regulators, sensors and switches that make everything from cars to phones to coffee makers and key fobs run — are becoming more essential every day. In the defense industry, these components have to be more reliable, customizable and secure than their commercial counterparts to ensure mission success.

"If a particular chip fails in your iPhone, you go back to the Apple store and get a replacement," says Matt Hicks, Director of Advanced Technology Labs (ATL). “That's simply not possible when a particular chip is on a mission, such as embedded on a satellite or a military plane.”

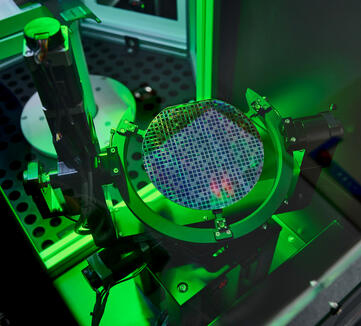

Hicks manages Northrop Grumman’s Advanced Technology Laboratory (ATL) a semiconductor foundry and test site in Linthicum Heights, Md. that provides mission-critical parts to the Department of Defense (DoD) and other U.S. Government agencies. In some defense programs, the unique environments in which microelectronics must survive drive exacting requirements such as high power, different frequencies or ability to withstand radiation from space. These are monumental requirements that must be resolved on the atomic level.

Even with the vast range of commercial microelectronics providers, there are some applications so unique to the defense industry’s needs that raw innovation is required. As a pioneer in microelectronics, Northrop Grumman supports hundreds of government programs and delivers millions of chips annually.

"When the commercial semiconductor industry, for whatever reason, business or technical, chooses not to provide a solution, the ATL’s semiconductor fab, test and assembly facilities step in and ensure that we can do what our warfighter needs," Hicks says.

A Balancing Act: Reliability vs. Innovation

Hicks and his team are responsible for building reliable components that meet these stringent requirements, first and foremost, but they also want to push the envelope and innovate to build parts that will advance the entire industry. Balancing reliability and innovation can be challenging.

On one side, ATL has 650 experienced technical staff members producing semiconductors. For example, they produce radiation-hardened chips that can withstand extreme environments, such as operating in space for decades.

"It is absolutely critical that we do everything we can to make sure that when we send something to space, it survives beyond the mission life," Hicks explains. "We actually have a memory chip that has survived over 50 years. Many of our chips are expected to last 20, 30, even 40 years in space with no faults or failures. Would you trust a car that is five decades old, that you can’t maintain or even turn on until you needed it to?"

With that type of legacy, ATL is busy producing more than a million devices each year. In fact, they have delivered more than 10 million parts to various defense-based production programs. To meet a broad range of warfighter and space exploration needs, they have more than 30 production processes in place today — and more in development.

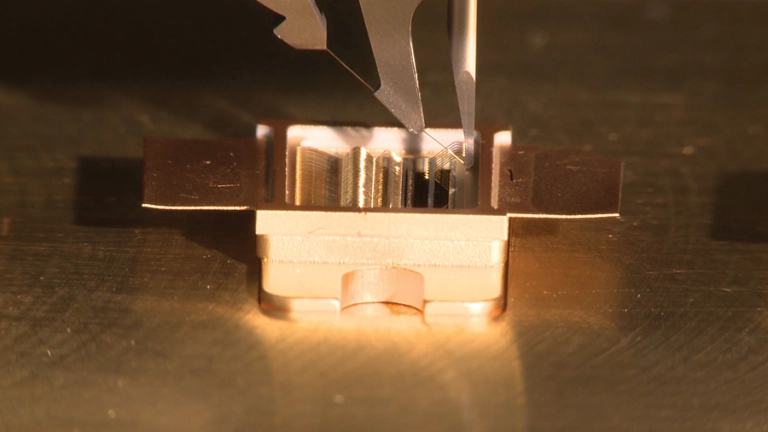

In addition, ATL has dozens of PhD-level subject matter experts working on inventing new materials and new processes. The research and development side of the organization works on creating new solutions to future problems.

Hicks says, "Northrop Grumman is figuring out what technology we're going to be producing five, 10 or 15 years from now — and how do we ensure that's the right technology for what the warfighters will need, even though we don't know what the battlefields will look like yet."

Baking Security into the Core

Underlying all the innovation, reliability and efficiency, security is always at the core of the business, forming the foundation on which all else is built.

"We are hypersensitive to concerns with cybersecurity and do the best we can to protect our intellectual property, so malicious actors don't have access to it," says Hicks.

The team makes a point to layer in multiple levels of security, whether that's ensuring that unauthorized people don't enter the building, preventing someone from infiltrating the network, or building security right into the components themselves. For example, they need to prevent bad actors from selling fraudulent copies of the components and passing them off as military-ready when they are actually only commercial microelectronics.

"We have the ability to embed signatures into our products that enable us to validate when they were produced, who produced them, etc." Hicks explains. This attention to security ensures the products are verifiably secure and can be trusted, even for the most sensitive of operations.

Embracing Digital Transformation

To meet the unique requirements of the job, Hicks and his colleagues at ATL have embraced Digital Transformation. "The idea is getting the most relevant data to the right place as fast as possible," he says.

They do this by leveraging augmented reality to diagnose problems and implementing big data analytics to "see through the forest" and identify what needs attention. They also use digital twins to mimic what the semiconductor production line does in a virtual fabrication environment, predicting and solving potential issues before building anything.

Semiconductor Innovation is a People-Focused Culture Driven by Creativity:

Ultimately, the best assets are the people who solve the problems. Hicks' team includes experts in a variety of STEM fields, including physicists, mathematicians, electrical engineers, mechanical engineers, industrial engineers, chemists, material scientists and business analysts.

More innovation stories

Read all stories about advanced technology and innovation >>