Clocking In

Northrop Grumman Explores New Ways to Make Designing Chips More Efficient

By Nestor Vences Gonzalez

Did you know that the miniature world of microelectronics relies on clocks to operate? Getting the timing right starts at the design stage, and a team at Northrop Grumman is leading the way in improving the process.

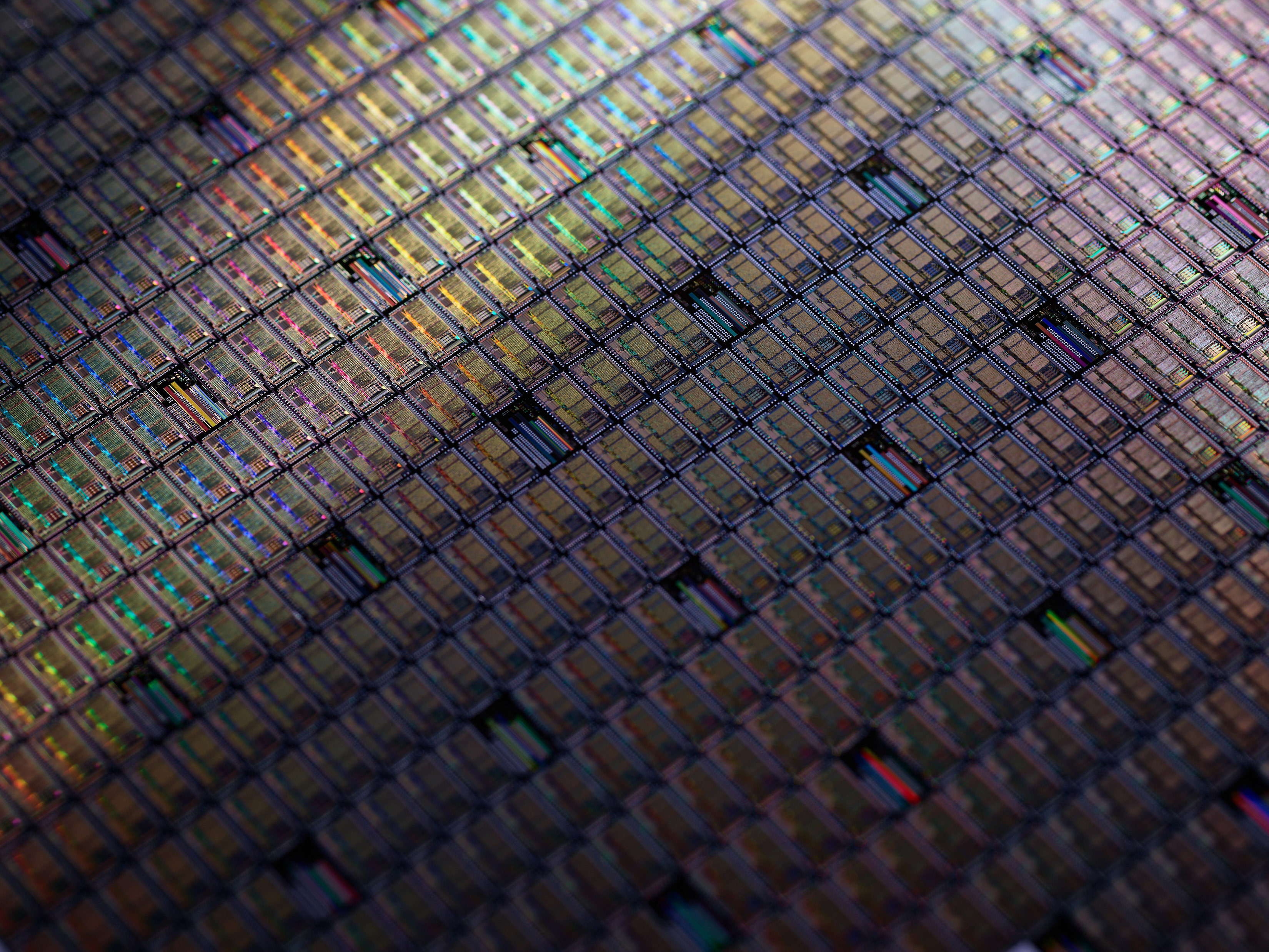

Today, microelectronics and chips can be found in a wide variety of devices, such as smartphones, cars and satellites. Powered by a series of circuits and transistors, chips carry electrical signals and information to enable your devices to perform tasks.

“Clocks are the heartbeat of the chips,” said Lisa Moy-Yee, the Northrop Grumman engineer leading the ASIC Clock project. “Clocks control the timing of all the operations, data, power management, and speed control inside a chip.”

In partnership with technology company Siemens Electronics Design Automation (Siemens EDA), Lisa is incorporating a tool into their design process that uses artificial intelligence (AI) to ensure chip clocks are communicating with each other harmoniously, slashing the time it takes to bring a chip from dream to reality.

Not Your Average Chips

As the need for missions grew more complex — for example the James Webb Space Telescope which looks at the origins of the universe — so did the need for specialized computing power. Enter application-specific integrated units (ASICs), which are circuits capable of packing in an entire circuit board's worth of electronics into a tiny package. Designing a chip that is increasingly complex requires rigorous analysis.

“End systems need computing, sensing and other data analysis — these clocks are essential in coordinating the complex processing and transfer of signals occurring within these tiny packages” said Ben Heying, director of the Space Park Foundry.

Asynchronous or unaligned clocks can also lead to costly schedule shifts and issues during integration and tests. The more complex the design is, the more scenarios a designer must verify to avoid asynchronous clock issues.

“With all chip designs, you need to make sure the clocks are communicating well with each other, or you’ll lose data,” Lisa said.No Second Guessing

“Complex ASICs, which power the most complex kinds of missions require lots of different clocks, sometimes 30, 40 or 50,” Lisa said.

When Lisa came across the opportunity to partner with Siemens EDA research and development team to implement a tool that helps designers analyze their designs using AI and machine learning, she jumped at the chance.

“I’m always looking for the latest and greatest of what's out there. I've always wanted to push technology,” Lisa said.

Together with Siemens EDA, Lisa customized the company’s cross-clock domain tool, which uses AI and ML, to cut a designer’s clock analysis time from eight weeks down to two weeks.

“Clock analysis can be very difficult and time consuming, and we want to identify any issues early in the design process,” Lisa said.

The tool analyzes databases to identify design areas that could generate issues down the line. Once identified, a designer modifies the design and ensures the clocks are running smoothly.

“Microelectronics design and development evolve at an astonishing rate and the need for specialized chips in the defense and commercial markets grows year over year,” said Mike Barsky, director of sales for the Northrop Grumman Microelectronics Center. “Accelerating the design cycle ensures our products are at the cutting edge of that market.”

“Cutting down the time it takes to analyze a design keeps programs on schedule within cost,” Lisa said, noting it also allows designers to make more complex designs. “For example, a television remote control chip may have one clock, while a chip in a satellite may have dozens of clocks.”

A New Bag

Since the 1950s, Northrop Grumman’s microelectronics leadership has played a role powering some of the most important defense and science missions of our time.

“Embracing AI and ML at the design phase of our microelectronics feels like a natural fit,” Lisa said, who hopes to reach out to more designers and encourage them to implement the tool in coming months. “Anything we can do to make ourselves more efficient is going to be a huge help in saving time and ultimately cost.”

Learn more about Northrop Grumman’s leadership in microelectronics.