Real-time Insights with a Future Bent

AI and Machine Learning Predict the Life of Systems with an OODA Loop

By Albert McKeon

People are often encouraged to listen to their bodies — to pay attention to aches and pains, so they can discern possible health issues. Thanks to artificial intelligence (AI) and machine learning (ML), technology might also be able to tell when a system or process is breaking down, giving users advanced warning of potential problems with critical and expensive systems.

Two Northrop Grumman engineers are researching the potential of combining a well-known decision-making theory — what is known as an OODA loop — with sensor data crunched by AI and ML to predict the lifespan of systems. Their study has parallels with the preventative healthcare of humans.

"It's analogous to having a bad toothache at 2 a.m.," said Anthony Alston, a senior staff systems engineer at Northrop Grumman and one of the researchers. "There's not much you can do at that time of the night. But if you knew about the toothache coming two days in advance, you'd be able to go to the dentist ahead of time."

Real-Time Data Helps Planning

Alston and his fellow researcher, Northrop Grumman Staff Systems Engineer Udi Vermesh, undertake their study as organizations put even greater faith in technology and electronic systems. Whether it's an autonomous system that powers an airplane, the connected landing gear of a spacecraft or the steering and navigation system on a ship, systems can take technological progress to new heights, but they can also sputter or halt.

"This provides the manager of a system better control of their budget," Alston said of their project. "Knowing a component can fail, you can schedule the maintenance and buy the replacement when it is needed."

It delivers real-time insight with a future bent, enabling organizations to have a lean inventory and not stockpile parts and technologies — because those excessive pieces can become obsolete before they're even used, he said. Similarly, organizations can use the predictive data to cross-reference financial, vendor and other data to see if a certain type of part continues to fail before it should, Vermesh said.

OODA loop is short for "observe, orient, detect and act." Devised by a Marine fighter pilot, the concept stresses repetition in a process or series of actions, with each of the four steps simultaneously feeding off one another to create an efficient seamlessness.

Alston and Vermesh believe the OODA loop can create a workflow for a system to use sensor monitoring data to look for threats to its own progress, including power failures and safety issues. Their research proposal posits that a recurrent neural network (RNN) model would use AI and ML to analyze historical and real-time data generated from device sensors.

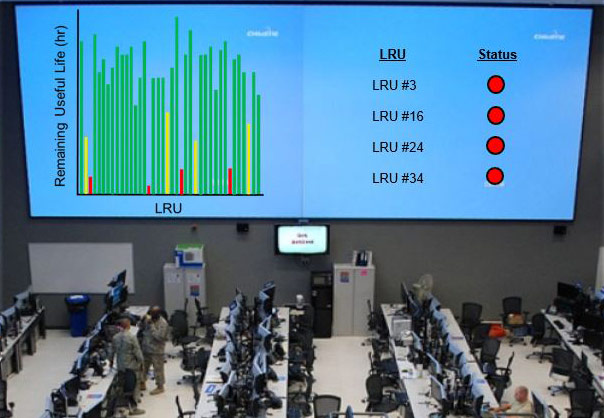

The prediction data would appear on a mechanism known as a common operating picture to provide a visual overview of the monitored system's status. The prediction results could also provide alerts to mobile devices, and they could form an action plan for the system to "self-heal."

AI can be modeled to look at sensor data for "outliers" — essentially, events that look abnormal.

"Say you have a power supply that has a known event of data," Alston said. "As the power supply degrades, that data pattern changes. Using AI, you can predict the change, that at some point in time this device might fail. Having an idea of when gives system administrators a fair warning that something bad is coming. Getting a text message at 2 a.m. that you need to fix a system at the last minute creates a snowball event if you're unprepared. When you're prepared, system administrators can schedule downtime at their own discretion."

Preparing and Calibrating an AI Model

Just as a system could be faulty, so too could the sensors that are monitoring the system. As part of their research, Alston and Vermesh will determine what sensors should look for, so they can provide accurate data. The frequency of vibration in a mechanical system, for one, can detect energy loss.

"You want to have things well calibrated beforehand and know that the sensors are looking at the right criteria," Vermesh said.

Their AI model also needs to detect false-positive results. "You want to assign a percentage of confidence, and that will take into account if it's a false-positive or a true event," Alston said. "You also don't want to have too many false-positives because then a system administrator will ignore the event. In the real world, ignoring a false alarm happens."

Bringing Different Skillsets to the AI Table

The research project makes them marvel at how technology has progressed over the years, to a point in which machine learning and AI can not only give instantaneous results but also predict the future. And that real-time perspective is what could give systems longer lives.

Alston and Vermesh have worked together previously and decided to join forces on the research project. They're both systems engineers but bring distinct skillsets to the table. Alston is the "AI guy," while Vermesh specializes in systems safety.

Vermesh has 15 years of experience in software development, systems engineering, system integration, and failure modes and effects analysis, and he's been with Northrop Grumman for a decade. Alston has more than 30 years of experience in software development, systems engineering, AI, system integration and cybersecurity, and he has been with the company for nearly three decades.

More Innovation Stories

Read all stories about advanced technology and innovation >>