Coating Capabilities

SYNOPTICS specializes in high Laser Damage Threshold coatings, utilizing the latest thin film coating technologies.

Ion Beam Sputtering (Conventional)

We offer traditional Ion Beam Sputtered coatings with conventional Ta2O5/SiO2 and HfO2/SiO2 discrete material thin film designs. Using this method, we can produce low loss coatings with either very low or very high reflectivity. Very precise anti-reflection coatings have been produced with R < 0.005% (50ppm) for both laser crystals and optical glasses. We can also produce high-reflector coatings with R > 99.99% for selected wavelengths. Ion Beam Sputtering is a precise deposition process and, when combined with our broad-band optical monitoring, allows us to produce accurate Dichroic, Beamsplitter, and Partial-Reflector coatings on a variety of materials. These coatings are very dense and do not have the water absorption/desorption spectral shift generally seen with Electron-Beam evaporated coatings. Our films are stable and environmentally robust.

Ion Beam Sputtering (Quasi-Rugate Structures)

Quasi-Rugate thin film designs are optimized for high power laser applications from ultra-fast to CW applications across the wavelength range of 355nm to 2200nm. Each design has a unique refractive index profile specifically tuned to give optimal performance for our customers' applications. Quasi-Rugate design structures have the highest demonstrated Laser Damage Thresholds of any Ion Beam Sputtered films.

Typical "AR" Specifications

- %R < 0.05% @ λ1

- LDT > 4GW/cm2, 1064nm, 7ns

- Surface Quality < 10-5

- Meet environmental specifications of Mil-C-48497

Electron-Beam Gun

We offer a special line of MaxCoat™ Electron-Beam (E-Beam) coatings that are optimized for high laser damage thresholds from 355nm – 2140nm. MaxCoat™ coating processes are tailored for specific applications from ultra-fast to CW and are available for all of our laser crystals and laser grade optics. E-Beam processing is the most commonly used deposition process for laser applications and is an economical solution for many applications that require high laser damage threshold coatings.

| MAXCOAT™ "AR" Designs | ||||||

|---|---|---|---|---|---|---|

| Design# | Crystal | Description | Typical Spectral Specification | Typical Laser Damage Threshold | ||

| Fluence | Power Density | Conditions | ||||

| A1500 | Nd:YAG | AR @ 1064nm | R < 0.2% | 60J/cm2 | 3GW/cm2 | 20ns, 20Hz, 0.5mm spot |

| A1505 | CTH:YAG | AR @ 2080-2140nm | R < 0.2% | 19kJ/cm2 | 126MW/cm2 | 150µs, 5Hz, 90µm spot |

| A2500 | Nd:YLF | AR @ 1047-1053nm | R < 0.2% | 60J/cm2 | 3GW/cm2 | 20ns, 20Hz, 0.5mm spot |

| A3500 | TGG | AR @ 1064nm | R < 0.2% | 60J/cm2 | 3GW/cm2 | 20ns, 20Hz, 0.5mm spot |

| A4500 | Nd:YVO4 | AR @ 1064nm | R < 0.2% | 60J/cm2 | 3GW/cm2 | 20ns, 20Hz, 0.5mm spot |

| A5100 | Alexandrite | AR @ 755nm, Long Pulse | R < 0.2% | 12.3kJ/cm2 | 61.5MW/cm2 | 200µs, 2Hz, 28µm spot |

| A5150 | Alexandrite | AR @ 755nm, Short Pulse | R < 0.2% | 9J/cm2 | 16GW/cm2 | 500ps, 5Hz, 2mm spot |

| A5203 | Co:Spinel | AR @ 1530-1550nm | R < 0.2% | 60J/cm2 | 3GW/cm2 | 20ns, 20Hz, 0.5mm spot |

| A5500 A5501 |

KTP | Dual AR @ 1064 & 532nm | R < 0.2% @ 1064nm R < 0.4% @ 532nm |

25J/cm2 12.5J/cm2 |

2.5GW/cm2 1.25GW/cm2 |

10ns, 20Hz, 1064nm 10ns, 20Hz, 532nm |

| A1501 | Nd:YAG | AR @ Nd:YAG λ's | R< 0.5% @ 1064-1440nm | 40J/cm2 | 2GW/cm2 | 20ns, 20Hz, 0.5mm spot |

| A1504 | Nd:YAG | DualAR @ 808 & 1064nm | R < 0.25% @ both | 40J/cm2 | 2GW/cm2 | 20ns, 20Hz, 0.5mm spot |

| A1523 | Nd:YAG | DualAR @ 1064 & 1319nm | R < 0.25% @ both | 40J/cm2 | 2GW/cm2 | 20ns, 20Hz, 0.5mm spot |

| A2501 | Nd:YLF | DualAR @ 808 & 1053nm | R < 0.25% @ both | 40J/cm2 | 2GW/cm2 | 20ns, 20Hz, 0.5mm spot |

| MAXCOAT™ "HR" Designs | ||||||

| Design# | Crystal | Description | Spectral Spec | Typical Laser Damage Threshold | ||

| Laser Fluence | Power Density | Conditions | ||||

| H1500 | Nd:YAG | HR @ 1064, HT @ 780-825nm | R > 99.9% T > 97.5% |

80J/cm2 | 4GW/cm2 | 20ns, 20Hz, 0.5mm spot |

| H2501 | Nd:YLF | HR @ 1053, HT @ 790-808nm | R > 99.5% T > 97% |

60J/cm2 | 3GW/cm2 | 20ns, 20Hz, 0.5mm spot |

Evaporative Thermal Source

We provide thermally evaporated single layer MgF2 coatings on Nd:YAG and TGG for select applications. Our proprietary process was developed to achieve maximum laser damage thresholds for this type of processing and we routinely produce coatings that exceed 40J/cm2, 20ns, 20Hz, 1064nm.

| Standard Single Layer MgF2 "AR" Coatings for YAG | |||

|---|---|---|---|

| Design# | Crystal | Description | Typical Spectral Specification |

| A1000 | Nd:YAG | AR @ 1064nm, 0° | R < 0.2% |

| A1006 | Nd:YAG | AR @ 808nm, 0° | R < 0.2% |

| A1017 | Nd:YAG | AR @ 532nm, 0° | R < 0.2% |

| A1074 | Nd:YAG | AR @ 1123nm, 0° | R < 0.2% |

| A1075 | Nd:YAG | AR @ 1319nm, 0° | R < 0.2% |

| A1079 | Nd:YAG | AR @ 1064nm, 15 - 30° | R < 0.25% |

| Standard Single Layer MgF2 "AR" Coatings for TGG | |||

|---|---|---|---|

| Design# | Crystal | Description | Typical Spectral Specification |

| A1131 | TGG | AR @ 1064nm, 0° | R < 0.1% |

| A1142 | TGG | AR @ 1000 - 1100, 0° | R < 0.25% |

| A1143 | TGG | AR @ 1550nm, 0° | R < 0.2% |

| A1145 | TGG | AR @ 1090nm, 0° | R < 0.2% |

| A1149 | TGG | AR @ 1336nm, 0° | R < 0.2% |

| A1157 | TGG | AR @ 780nm, 0° | R < 0.2% |

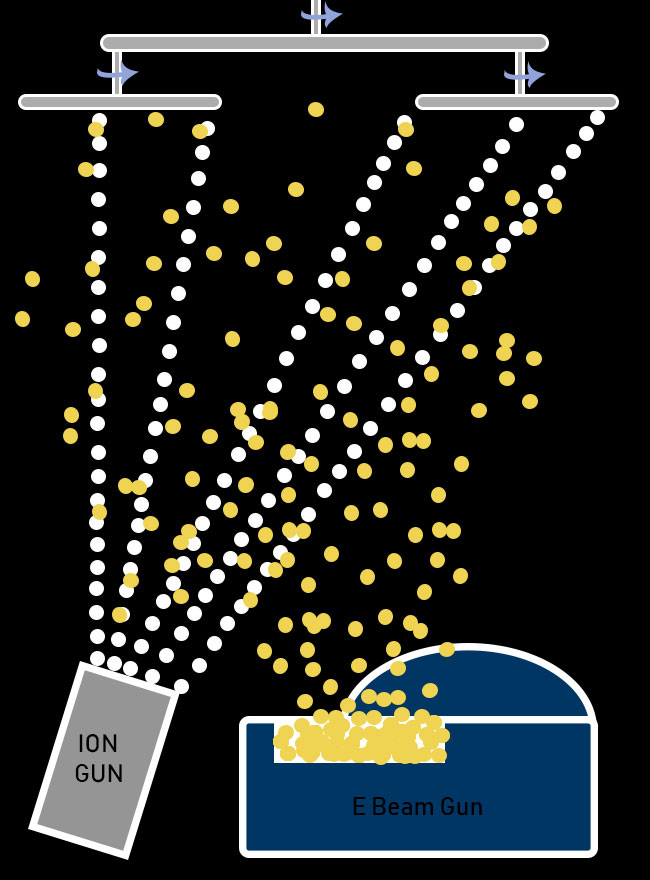

Ion Assist Electron-Beam

In conjunction with our E-Beam coating we have the capability of doing Ion-Assisted Deposition (IAD) for applications that require thin films with high packing density but still require the attributes of E-Beam coatings. In this process a directed low energy ion beam is introduced to the E-Beam coating process to add energy and accelerate the coating molecules to the substrate. This is a low temperature process and can be used on substrates that are sensitive to heat.

Comparison Matrix

| | 1Thermal Evaporation | E-Beam Evaporation | Ion-Assist E-Beam Evaporation | IBS Traditional | IBS Quasi-Rugate |

|---|---|---|---|---|---|

| Cost | $ | $$ | $$ | $$$$ | $$$$ |

| Load Capacity | Moderate | High | High | Moderate | Moderate |

| Precision | Moderate | Good | Good | Excellent | Excellent |

| Run to Run Variance | Moderate | Good | Good | Excellent | Excellent |

| Density | Porous | Porous | Dense | Near Bulk | Near Bulk |

| Water Shift | High | Moderate | Low | None | None |

| Surface Roughness | ≈10-15ÅRMS | ≈8-10ÅRMS | ≈6ÅRMS | < 1ÅRMS | < 1ÅRMS |

| Durability | Moderate | Good | Very Good | Excellent | Excellent |

| Laser Damage Threshold (1064nm AR) | Good | Excellent | Very Good | Moderate | Excellent |

| Lowest %R build spec | R <0.1%@λI | R <0.05%@λI | R <0.05%@λI | R <0.005%@λI | R <0.02%@λI |

1 - Thermal evaporation coatings limited to single layer Magnesium Fluoride on Nd:YAG and TGG

Contact Us

Northrop Grumman SYNOPTICS

1201 Continental Boulevard

Charlotte, NC 28273

Phone: 704-588-2340 | Fax: 704-583-5851

Contact Us