High Power Laser Beam Control

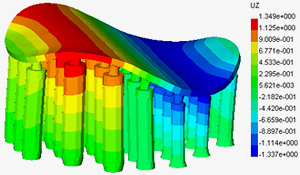

Adaptive optics (AO) has a crucial role in high power laser development within the cavity of the device itself. Many modern High Energy laser (HEL) designs use exotic cavity geometries and/or gain mediums that are sensitive to heat, vibration, and other environmental stresses. AO is necessary to adjust the wavefront inside the cavity to ensure that the oscillating mode is tuned for maximum efficiency.