Deformable Mirrors

AOA Xinetics fabricates the highest quality deformable mirrors in the world today.

AOA Xinetics fabricates the highest quality deformable mirrors in the world today.

AOA Xinetics fabricates the highest quality deformable mirrors in the world today. Our DMs were critical to many advances in wavefront control, including the first images of individual photoreceptors in the living human retina (1996), the first demonstration of dimensionally stable response when exposed to the 0 Celsius ambient conditions of Mauna Kea (1997), the first demonstration of high-energy laser train operation without using liquid cooling (1998), and the first demonstration of ten-fold fluence increase by using beam cleanup in a femtosecond pulsed laser (2000). We maintain our leadership by continuous development of novel deformable mirror technology that increases channel density, improves thermal stability, reduces mass and package size, bolsters stroke limits, and provides higher precision correction.

The design goal has always been to build mirrors that are optically stable to the angstrom level with actuators that have lifetimes that should be statistically nearly infinite when operated under specific conditions. Our surface normal actuated (SNA) commercial DMs are made with discrete high reliability lead magnesium niobate (PMN) electroceramic actuators. The DMs achieve 4 μm of stroke displacement and are spaced 5 mm or 7 mm apart to form the basic actuator array, with up to 941 channels. Custom DMs have been fabricated with acutator spacings up to 33mm, or up to 22 μm of stroke.

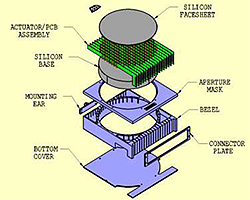

Modular DM Assembly

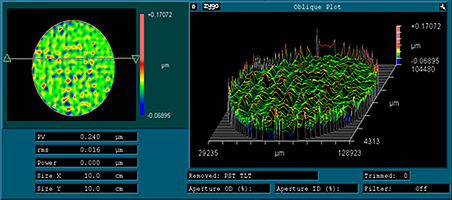

Measured response of 349ch deformable mirror after flattening commands. The residual figure error of 16 nm rms is typical for SNA DMs.

SNA DMs feature a continuous facesheet of ULE or single crystal silicon for directed energy applications. To minimize thermal distortions, the acutuators are athermally bonded to the rigid reaction structure, which is fabricated from the same material as facesheet. Apertures up to 30 cm are available. Fast actuator rise time of 100μs (99% settled) enables > 5 kHz small signal bandwidth.

AOA Xinetics standard deformable mirror designs utilize a modular assembly approach. Its distinguishing feature is the single optical assembly consisting of base, actuators, and facesheet potted inside a metal bezel. The RTV potting prevents thermal distortions of the optical components by absorbing any differential expansion between the metal bezel and optical assembly. A single board accepts the actuator wires and relays the signals to individual connectors. These connectors provide the interface to the driver electronics.

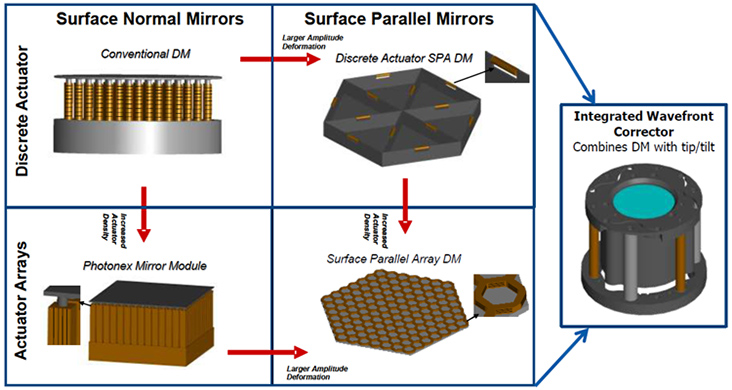

Advanced deformable mirrors utilize novel actuator technologies for precision control of optical surfaces

For actuator spacings less than 5 mm, AOA Xinetics has developed Photonex Integrated Module technology. The major problems in making high density deformable mirrors are the structural interface and the electrical connection. Using three-dimensional ceramic processing, a monolithic block is formed that contains an integrated actuator array. With its built-in electrical interface, the modular array resolves the greatest limitation to channel scaling and actuator density – the electrical interconnects.

Anamorphic Photonex Modules

By incorporating microcircuit technology, interconnection to individual actuators is done without labor-intensive discrete processing. Eliminating discrete actuator wiring increases the actuator fill factor, improves optical quality and enhances actuator reliability. In this way the connections at made at the back while allowing these discrete units to be bonded together to form larger arrays as needed. Photonex modules have been made with actuator spacing of 2.5 mm, 1.8 mm, and 1 mm and can contain up to 4,096 actuators.

Surface Parallel Array (SPA) holds great promise for the next generation of Deformable Mirrors (DMs) as well as active control of large scale optics. Actuators integrated within the mirror base in a surface parallel orientation provide low amplitude mirror shape control compatible with thermal induced distortions. SPA technology allows much greater stroke range and is much simpler and lighter than traditional SNA DMs. A nominal total stroke of 50 microns is achievable without sacrificing active flattening precision (8 nm rms has been demonstrated). A new level of optical figure control becomes possible by integrating an SPA into a large, lightweight optic. Because no reaction structure is required, SPA technology does not result in a significant weight increase but it does result in an increase in the effective stiffness of the optic via active control.

SPA actuator array, 420 elements

The behavior of the SPA is fundamentally different form the traditional surface normal actuation. The influence function of each actuator extends over the whole surface of the mirror; a global influence function. Traditional analysis and algorithms written to control mirrors with localized influence functions are not optimal for SPA devices. AOA Xinetics has developed, and continues to develop, wavefront control processes to maximize effective use of SPA DMs.