How Northrop Grumman produces a fuselage every 30 hours

Advanced Aircraft, Automated Production

Bringing Scale & Speed to F-35 Manufacturing

Seeking creative, innovative ways of maintaining demanding production rates while remaining focused on quality and affordability is key to the growth of the F-35 program at Northrop Grumman. The company’s advanced manufacturing expertise is a key factor that enables the F-35 center fuselage production at speed and scale.

In late 2001, Northrop Grumman was named a principal member of the Lockheed Martin-led industry team that is developing, producing and sustaining three variants of the stealthy, multi-role F-35 Lightning II. Meeting the high-rate production needs for the program meant incorporating greater automation capabilities and cutting-edge robotics.

In addition to the center fuselage, Northrop Grumman produces multiple mission systems that serve as the F-35’s eyes and ears in the sky and provide the pilot with unmatched performance and situational awareness.

This includes its integrated Communications, Navigation and Identification (CNI) system, AN/APG-81 radar and sustainment of the Electro-Optical Distributed Aperture System (EODAS). The team also delivers technology infused global sustainment and modernization to ensure the F-35 fleet around the world maintains mission readiness.

Counting on Automation to Improve the F-35 Production

"We knew that automation and robotics would be key to meeting the F-35 program's goal of continued high-volume production," says Glenn Masukawa, vice president and F-35 program manager at Northrop Grumman. "We also needed to be affordable, which implied a lot of cost reductions over time."

Northrop Grumman had previously pioneered automated manufacturing systems to produce key subassemblies for military aircraft. However, the new expectation set was for a production interval of one day -- a goal that would test even the most advanced aircraft assembly lines in the world

Learning from Automakers to Develop an Integrated Manufacturing System

To meet this challenge, the company turned to a comparable high-rate production industry in the country: the U.S. automotive industry.

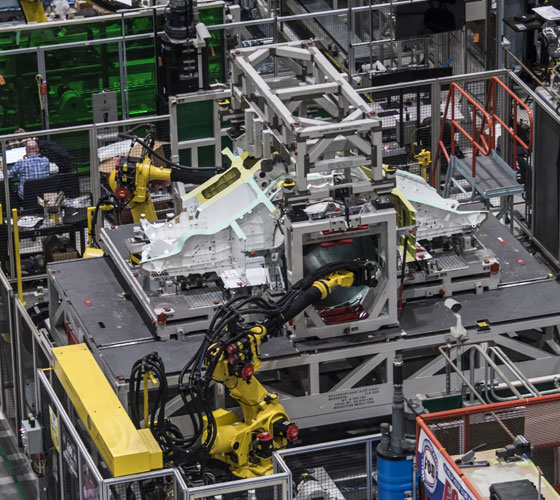

"We teamed up with KUKA Systems North America, a Detroit-based automation technology company that specialized in integrating assembly lines for the automotive industry," explains Scott Johnson, F-35 center fuselage integrated product team lead. "We blended their understanding of automation and automotive production lines with our expertise in aerospace tooling. The resulting Integrated Assembly Line (IAL) represents the best production practices from both industries."

The IAL was also an opportunity to eliminate previous standalone islands in the company's F-35 manufacturing process and develop an automated approach to manufacturing the center fuselage, he adds.

Meeting Production Goals

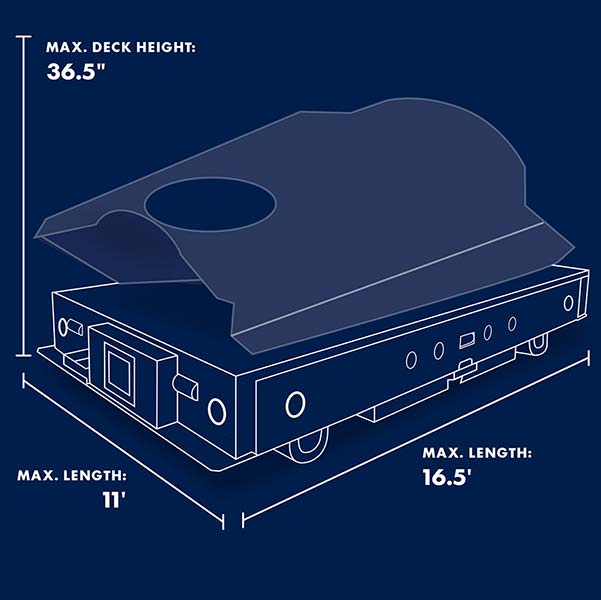

The U-shaped IAL is located at Northrop Grumman's Aircraft Integration Center of Excellence in Palmdale, California. It comprises more than 115 build stations and 22 automated systems designed to enhance quality, safety and affordability. Now operating at full production, the IAL currently completes an F-35 center fuselage every 30 hours, which corresponds to a production interval of 1.25 days.

To date, Northrop Grumman has delivered more than 1,400 F-35 center fuselages.

Going Three-on-One

According to Johnson, one of the most remarkable aspects of the IAL is that it produces all three F-35 variants — Conventional Takeoff and Landing (CTOL), Carrier Variant (CV), and the Short Takeoff Vertical Landing (STOVL) — at the same time.

"All three variants use the same base tooling," Johnson says. "Our secret sauce, however, is Northrop Grumman's very robust global supply chain."

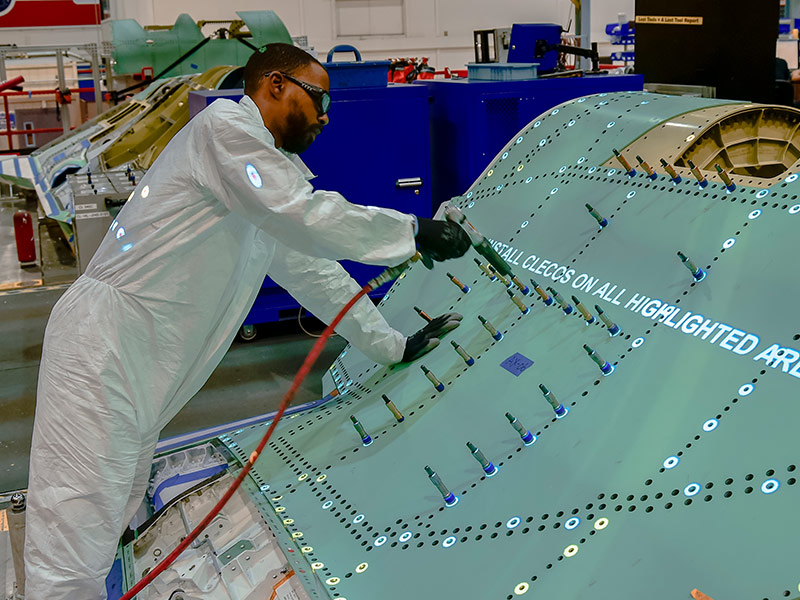

He notes that the supply chain team helped to develop a very methodical process for delivering parts to the IAL using containers called "shadow boxes." Each box contains foam cutouts for the specific parts that mechanics need to install on each center fuselage. Once those parts have been installed, the team picks up the empty box and refills it for the next variant coming down the line. This makes multi-variant production, on a single production line, a seamless endeavor.

"This simple but very effective process means that we have near-perfect accuracy in installing the right part on the right jet," says Masukawa.

American Manufacturing for Global Security

With nearly 100,000 employees and over 30 million square feet of manufacturing space across America – more than 500 football fields – Northrop Grumman has the capacity, scale, and agility to drive innovation at unprecedented speeds. The company leads the industry in digital design, manufacturing and modernization, saving time and cost by putting technology to the test and ensuring its reliability and survivability long before manufacturing occurs.

The company’s manufacturing approach does more than just produce; they accelerate and enhance the entire process from design and development to production and testing.

Northrop Grumman has invested billions of dollars in its workforce and supply chain and added over $13.5 billion in U.S. infrastructure and R&D to deliver today and tomorrow’s national security needs.

Summary

Northrop Grumman’s Integrated Assembly Line (IAL) efficiently produces the F-35 center fuselage, leveraging automation and robotics to achieve high production rates without compromising quality or affordability.

Key Takeaway

- The IAL uses advanced manufacturing to produce center fuselages for three F-35 variants on one production line.

- Northrop Grumman's automated production systems ensure quality while meeting rigorous production demands for the F-35 program.