Northrop Grumman’s hydrotesting team ensures the durability of solid rocket motors which power missions to the moon and beyond.

Boosting Production

Delivering Solid Rocket Motors at Record Rates

By Jordan Orris & Hillary Walker

In a dynamic geopolitical environment with rapidly evolving threats, the United States and its allies need next-generation solid rocket motors (SRMs) that travel farther, faster and with greater force to propel national defense, missile deterrence and rapid response missions.

Answering the call, Northrop Grumman is scaling production and quickly fielding new capabilities to deliver SRMs at a record pace. To date, we’ve delivered more than 1.3 million SRMs – ranging in size from a few inches to over 12 feet in diameter – that provide the Department of Defense (DoD), NASA and American allies with propulsion capabilities to deter and defend against missile threats, deliver payloads into space and enable discovery beyond our own planet.

“Our goals are clear: we are expediting delivery, expanding range, and enhancing the performance of our rocket motors, all while pushing the boundaries of physics,” said Erik Buice, vice president of missile products.

Scaling Fast: Investing for Capacity

Northrop Grumman has invested more than $1 billion over the last seven years in facility expansion and modernization, which has boosted propellant capacity and increased our existing nationwide footprint by nearly one million square feet of advanced manufacturing facilities supporting propulsion.

"By 2027, we will be ready to double our SRM production capacity,” said Jim Kalberer, vice president of propulsion systems. “This growth reflects our readiness to support a significant surge in SRM demand, driven by an increased interest in space exploration and ongoing global unrest. We foresaw the need years ago and began investing in new facilities accordingly. Today, we are well-prepared for the increased production cadence.”

This expansion also supports our commitment to an American-based supply chain and skilled domestic workforce. From site to site, thousands of engineers, technicians and suppliers are working together to meet growing demand.

“Our investments in infrastructure, research and development, American sources of supply, and a highly skilled workforce are designed to meet both today’s and tomorrow’s national security needs,” said Gordon LoPresti, senior director of propulsion systems and controls. “ All of these factors are key enablers in our ability to turn around SRM designs so rapidly.”

Digital Edge, Proven Propulsion Heritage

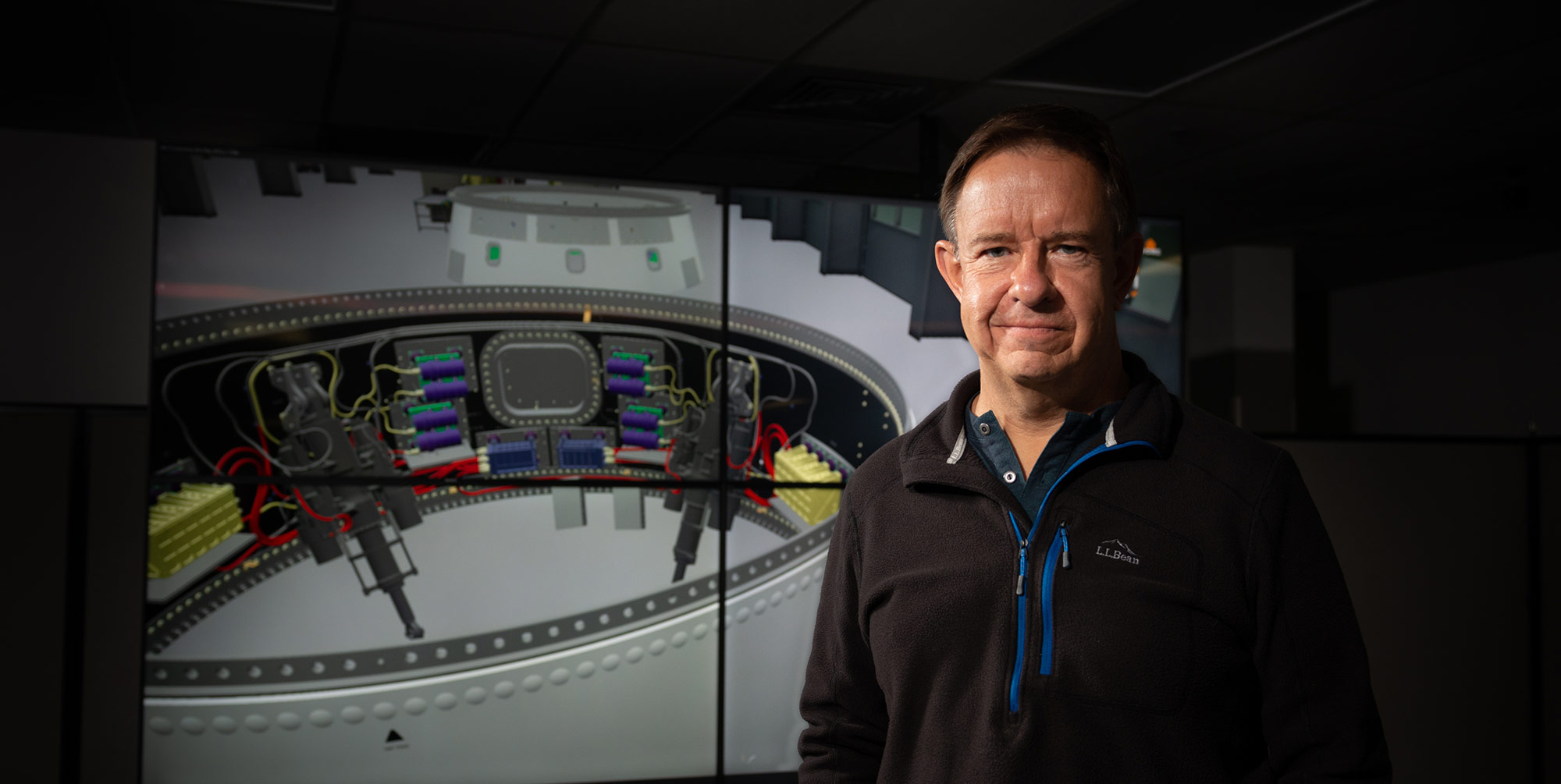

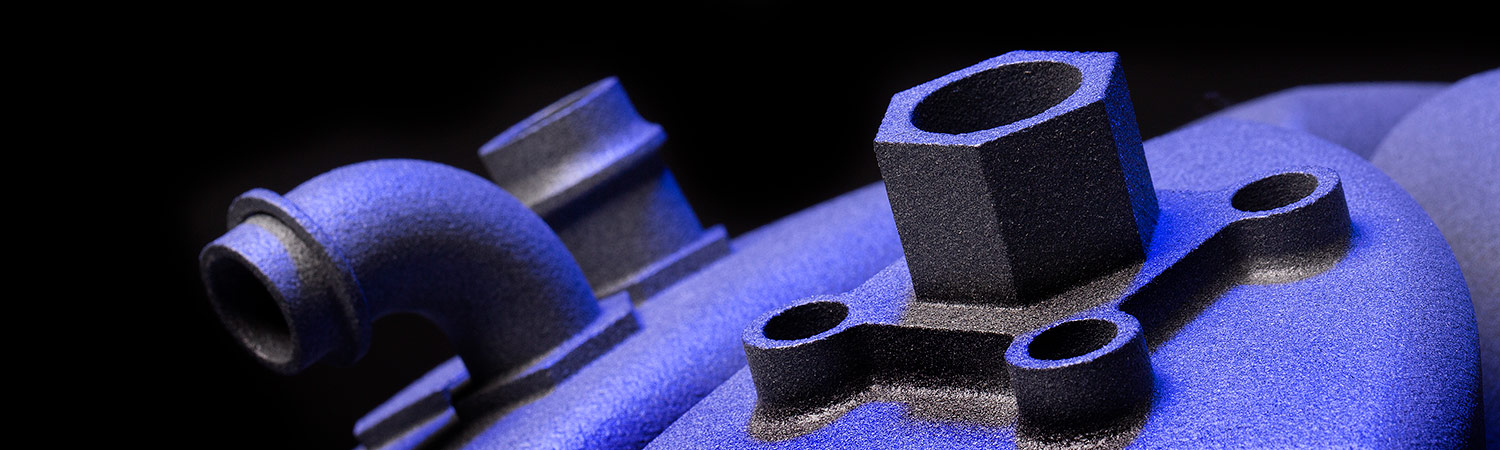

Northrop Grumman’s digital transformation is driving down production timelines and costs. Integrated tools like modeling, simulation, artificial intelligence, machine learning, additive manufacturing, and virtual reality are accelerating collaboration, automating processes and optimizing every step of development.

“Each platform helps us model, monitor and deliver more effectively, each increasing collaboration and efficiency, while saving time and money,” said Jessica Ramsay, staff engineer, digital engineering & data.

This forward-leaning approach is grounded in a rich history of innovation. Our facilities in Utah, Elkton and at Allegany Ballistics Laboratory (ABL) have powered American defense for more than 65 years, with roots dating back to World War II-era propulsion lines.

“These sites form the backbone of our SRM production,” Jim said. “We’re no stranger to meeting American needs when our country needs it most.”

AI and Machine Learning

Additive Manufacturing

Trusted Partnerships, Global Impact

Northrop Grumman’s SRM production facilities are a true national asset. “Our ABL facility exemplifies our strong manufacturing partnership with the U.S. Government,” Erik said. “We have a long-term lease with the Navy. The Navy owns two plants on the campus, and strategic Northrop Grumman investments have expanded the facility to five total plants.”

The Bacchus site also hosts a Navy-owned, Northrop Grumman-run facility. We partner with the DoD to serve their unique needs and are a trusted partner.

That trust, built over decades, is matched by a relentless drive toward what’s next. With facilities in all 50 states, wide-reaching infrastructure, a legacy of innovation and an experienced workforce, Northrop Grumman is prepared to support our customers’ most critical missions, including space launch, space exploration and national security and defense.

Explore how Northrop Grumman is shaping the future of propulsion technology and how you can get involved with career opportunities.

Summary

Northrop Grumman is rapidly increasing solid rocket motor production to meet defense and space exploration demands, investing over $1 billion to expand capacity and leverage digital advancements for efficient manufacturing.

Key Takeaways

- Northrop Grumman has delivered over 1.3 million solid rocket motors with plans to double production capacity by 2027.

- Investments in advanced technologies like digital modeling, AI, and material improvement are optimizing manufacturing processes to reduce production timeline and cost.

Recommended Stories

We mean it when we say anything is possible at Northrop Grumman – and our colleagues are proof of this. With the immense scale and scope of our business, you can shape your career journey with diverse roles and experiences that expand your expertise, feed your curiosity, and fuel your passion.

We are proud to share the stories of our colleagues to inspire future generations.