Systems Engineer Rebecca Peterson wants to bring a new reality to employees across Northrop Grumman.

Thrusters All Go

Transforming Satellite Creation

By Nestor Vences Gonzalez

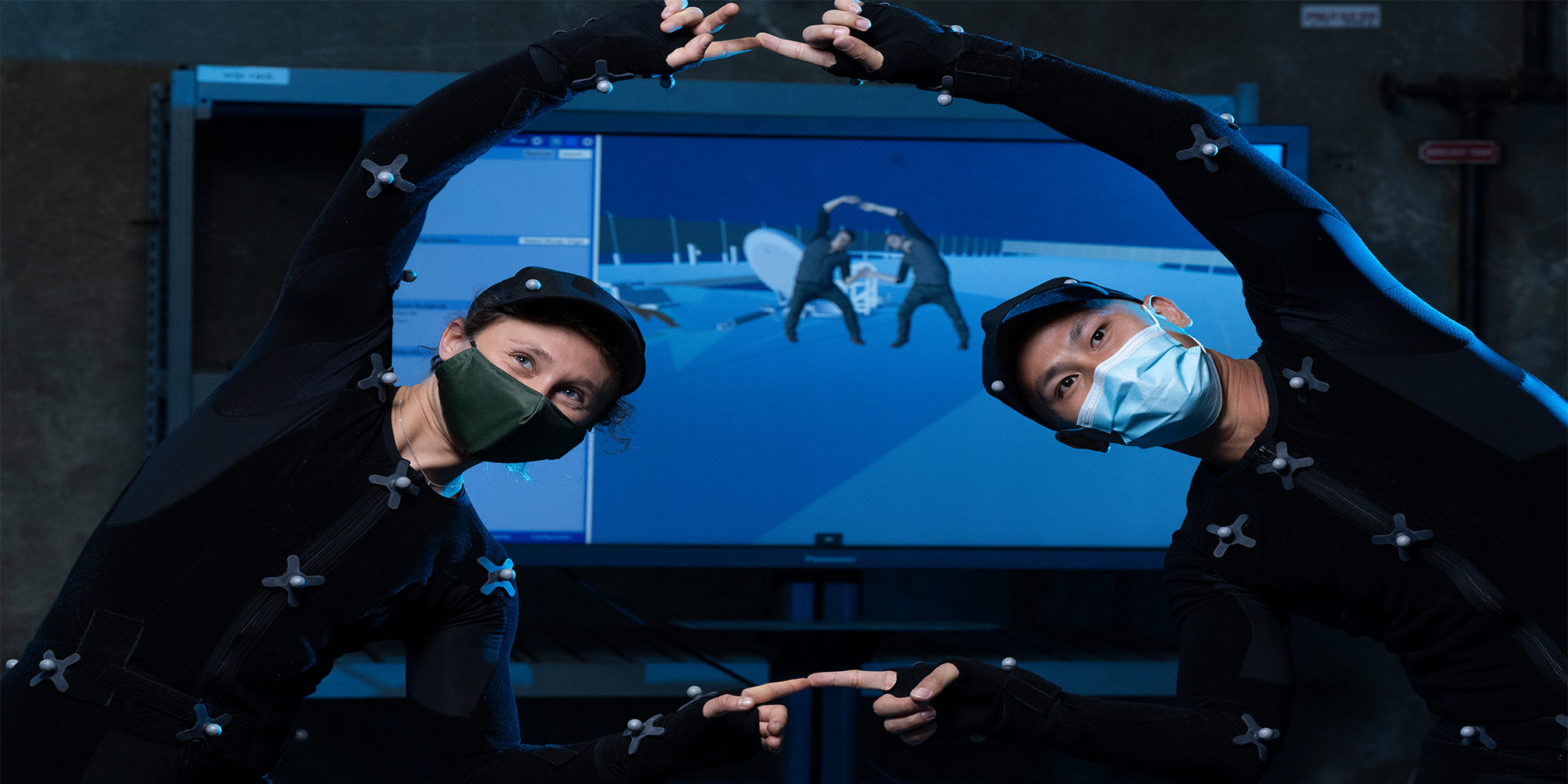

When Jonathan Chang, a mechanical assembly and integration manager, puts on the Highly Immersive Virtual Environment’s (HIVE) full body suit, he is stepping into a dream come true.

The HIVE is a mixed reality world where physical surroundings blend with a spacecraft’s digital model — enabling Jonathan to see a satellite as it’s still being designed and give valuable feedback before the first part is even shipped.

“You get so much more context with the 3D environment. It’s a big plus. In the past, we’ve done full mockups to do different evaluations; with the HIVE we’re saving costs, avoiding over-building, and completing pre-assessments,” he said.

Jonathan leads the team responsible for mechanical assembly, integration and test on the Next-Generation Overhead Persistent Infrared Polar (NGP) program. Using advanced infrared sensors, NGP will detect and track ballistic and hypersonic missiles over the Northern Hemisphere.

Northrop Grumman has supported missile warning and defense for decades, most recently providing the payload for the legacy Space-Based Infrared Systems, the program NGP will succeed.

In his two decades of experience, Jonathan thought he had seen it all.

Construction Revolution

Enter the HIVE — a system that combines a full body suit and motion capture nodules to let users interact directly with spacecraft models in mixed reality. On NGP, HIVE supports the design process, enabling test engineers to simulate how technicians will integrate and assemble the satellites’ key components.

“Our test engineers write procedures to build and test the space vehicles, then our technicians take those instructions and turn them into reality,” said Jonathan. “The HIVE allows us to look at trends, people’s body mechanics and behaviors.”

Now that NGP has moved onto its manufacturing phase, HIVE’s role has been amplified. Prior to the implementation of the HIVE, any design issues that were identified after building the prototype that required a redesign, required the process to start again. With HIVE, engineers can test and develop spacecraft, using HIVE’s combination of the physical world and a digital model, to identify design issues before physical prototyping.

“It allows us to change the way we design if we need to, see things that aren’t apparent in the 3D model on our computer screens,” Jonathan said.

Anticipating the Needs of Tomorrow

On programs like NGP, the HIVE has proven its worth, said Technician James Gutierrez, who has worked with the HIVE and used it to identify an improvement for NGP’s thruster design.

“While training on NGP in the virtual HIVE environment, we were always reminding teammates to be careful of the position of the thrusters so they wouldn’t accidentally get too close and damage them,” said James.

The team did, ultimately making a pre-production design change to the thrusters that saved the program from potentially wasting time or physical resources down the road.

“As much as we try to design all the problems you think about on paper, you always find challenges in person,” Jonathan said.

Although a primary goal of the HIVE has been to study human factors, such as ergonomics and safety, it has helped with an unexpected area: knowledge transfer.

“My favorite part of the job is passing along my experience and knowledge to someone else,” said James, who has been working in manufacturing, assembly and integration for 29 years.

The HIVE allows technicians who typically would not see hardware or a spacecraft until many years into their careers begin to provide immediate feedback on the hardware, ergonomics and accessibility.

“I like using the HIVE with new technicians. I say, ‘Let's introduce you to a spacecraft, so you can see what we're talking about,’” James said. “It’s been a total game changer.”

Learn more about how Northrop Grumman is empowering its teams through digital transformation.

Life at Northrop Grumman

Your work at Northrop Grumman makes a difference. Whether you want to design next-generation aircraft, harness digital technologies or build spacecraft that will return humanity to the moon, you’ll contribute to technology that’s transforming the world. Check out our career opportunities to see how you can help define possible.