Propulsion Products and Services

A complete range of propulsion products and services to develop and produce high quality flight hardware.

Northrop Grumman offers a complete range of propulsion products and services to develop and produce high quality flight hardware.

The reliability of our propulsion products has been proven over four decades of flight experience - no spacecraft, launcher or missile has failed because of a failure in a Northrop Grumman-built propulsion system. Further, no Northrop Grumman bipropellant or gel rocket engine has ever suffered a flight failure in more than 100 separate missions for a wide variety of programs.

Current Northrop Grumman propulsion products include flight-proven systems, bipropellant engines and thrusters, monopropellant thrusters, and gel propulsion systems. A line of standard components help provide best value - required performance with high reliability at low cost - for our customers.

Northrop Grumman's propulsion-related services include engineering, fabrication, integration, testing and documentation. Our highly experienced engineering staff is expert in the design, analyses and testing of propulsion components and integrated systems. Our chemistry technology capability provides a full range of analytical support for propellant and rocket materials development.

Propulsion Systems Analyses

The Propulsion Systems Center has the extensive analysis experience, capabilities and tools needed to design propulsion systems, high-energy lasers and cryogenic coolers.

Combustor Performance

Analyses include the effects of non-equilibrium chemistry and multiple phases. A detailed combustor analysis (3-dimensional, non-equilibrium chemistry) to evaluate heat transfer and combustion efficiency was central to the design of Northrop Grumman's advanced Dual Mode Thruster.

Plume Effects

Plume effects analysis capabilities include evaluating high altitude plume effects (plume impingement and contamination) and plume signatures (IR, VUV and millimeter wave) using direct simulation Monte Carlo simulation. Plume signature analyses incorporate proprietary methods for all types of thrusters over a wide span of wavelengths.

Propellant Management and Slosh Effects

Propellant management device and propellant slosh characterization capabilities range from micro-gravity to launch environments. Several detailed computational fluid dynamics (CFD) tools support these design efforts.

Structural, Dynamics, Heat Transfer

Design analysis of propulsion, HEL, and cryogenic-cooler system components using commercial software tools (e.g., ANSYS).

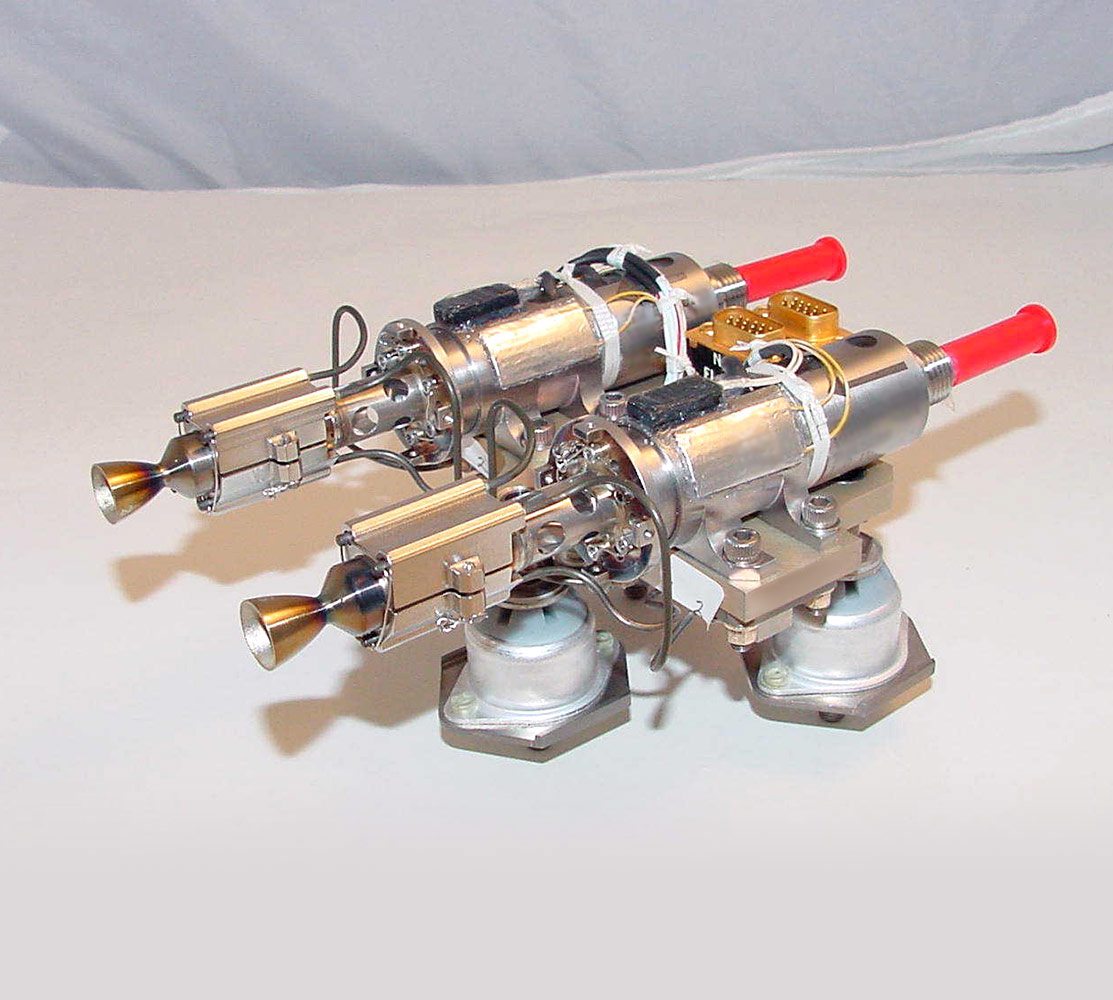

Bipropellant Engines and Thrusters

Northrop Grumman continues to develop new bipropellant engines and thrusters in response to customer needs. Northrop Grumman has a long heritage of design, manufacture, integration and testing of bipropellant systems for satellites and spacecraft. Recent development activities have focused on Reaction Control Systems (RCS) engine alternatives for NASA's Space Exploration Systems.

Northrop Grumman's current product line of bipropellant rockets includes:

- TR-308 Liquid Apogee Engine, which placed the NASA Chandra X-ray Observatory spacecraft into its final orbit. The Liquid Apogee Engine (LAE) is the world's highest performing apogee engine.

- TR-312 Liquid Apogee Engines (TR-312-100MN and TR-312-100YN) which have completed DVT testing for commerical geostationary comsat applications.

- TR-500 Dual Mode Thruster (DMT), flight-proven on the National Reconnaissance Office's Geosynchronous Lightweight Technology Experiment (GeoLITE) program.

- TR-501 Dual Mode Thruster (DMT) is the first truly dual-mode thruster to be flight qualified for both bipropellant and monopropellant modes.

- TR-711 Gel Boost Engine, which powered the world's first flight of a tactical missile utilizing gelled propellants and achieved a 700:1 Thurst-to-Weight Ratio.

- LOX/LH2 and LOX/Ethanol RCS engines successfully test fired in 1000 lbf and 870 lbf configurations, respectively.

- NASA RCE contract for a 100 lbf class LOX/Methane.

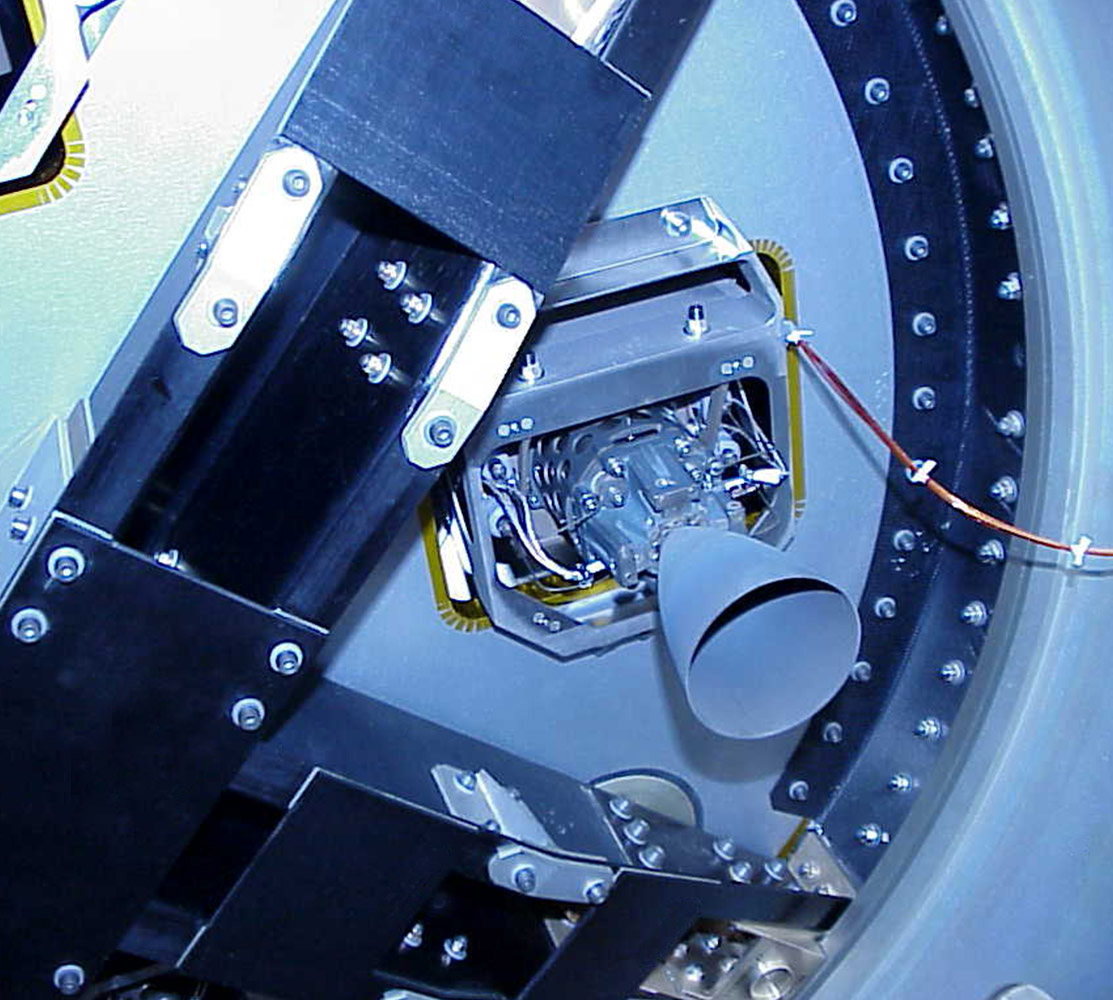

Propulsion Systems

Northrop Grumman has a heritage of propulsion system flight successes with more than 90 liquid propulsion systems meeting or exceeding mission goals since 1958. Northrop Grumman's flight-proven heritage ranges from the TDRSS Flight 1 hydrazine system that raised this satellite to operational altitude using 1 lbf thrusters after an upper stage failure, to the system for NASA's Chandra X-ray Observatory, that features over-wrapped, thin-wall propellant tanks and the highest performing dual-mode liquid apogee engines ever flown.

Northrop Grumman also has developed propulsion systems for kinetic kill vehicles, missiles and ejection seats. Our gel propulsion system provides smart flight for tactical missile systems.

Monopropellant Thrusters

Northrop Grumman has developed, qualified and flown nearly 1,000 monopropellant thrusters, gas generators and gas thrusters, ranging from 30 millipounds to 8 lbs. We have also developed and tested 15-pound class and larger monopropellant thrusters. In all cases, Northrop Grumman thrusters have exceeded design goals and outlived the useful spacecraft lives on a wide range of myriad of programs, including Pioneer 10 and 11, DSP, TDRS, FSC, Chandra X-ray Observatory, SOHO, EOS, TOMS, STEP, ROCSAT, KOMPSAT, and HEAO.

| MRE-0.0 (Gas Generator) Operating Pressure Range: Width x Length: Weight (STM): Maximum Throughput |

150-600 psla 13 x 65 mm 1.6 kg 27 kg |

| MRE-0.1 Thrust @ Maximum Operating Pressure: Steady-State Impulse: Operating Pressure Range: Width x Length: Weight (STM): Maximum Throughput: |

0.4 N @ 350 psia 216 sec 70-420 psla 180 x 38 mm 0.5 kg 34 kg |

| MRE-1.0 Thrust @ Maximum Operating Pressure: Steady-State Impulse: Operating Pressure Range: Width x Length: Weight (STM): Maximum Throughput: |

4.4 N @ 400 psia 218 sec 50-400 psla 38 x 191 0.5 kg 122 kg |

| MRE-4.0 Thrust @ Maximum Operating Pressure: Steady-State Impulse: Operating Pressure Range: Width x Length: Weight (STM): Maximum Throughput: |

18 N @ 600 psia 217 sec 50-600 psla 61 x 206 mm 0.5 kg 249 kg |

| MRE-5.0 Thrust @ Maximum Operating Pressure: Steady-State Impulse: Operating Pressure Range: Width x Length: Weight (STM): Maximum Throughput: |

22 N @ 400 psia 232 sec 70-400 psla 250 x 38 mm 0.8 kg 456 kg |

| MRE-15 Thrust @ Maximum Operating Pressure: Steady-State Impulse: Operating Pressure Range: Width x Length: Weight (STM): Maximum Throughput: |

86 N @ 400 psia 228 sec 138-430 psla 119 x 318 mm 1.1 kg 970 kg |

Related News

Fabrication of Northrop Grumman-Built Spacecraft for NASA's James Webb Space Telescope Moves Forward With Design Completion of Key Communications Structure

Northrop Grumman-Built STSS Demonstration Satellites Participate in Test of Next-Generation Aegis Ballistic Missile Defense Weapon System