“This is where I want to be,” Paul says as he joins his engineering colleagues, down the hall from the janitor’s closet which once held the keys to his success.

Microscopic Giants

Northrop Grumman’s Microelectronics Powering American Defense

Summary

Northrop Grumman manufactures advanced microelectronics, including the fastest microchip, enhancing U.S. defense capabilities. By expanding domestic production, the company ensures supply chain security, invests in innovation, and supports American workers in semiconductor manufacturing.

Key Takeaways

- Northrop Grumman produces millions of microchips annually, enhancing mission capabilities while securing the supply chain for U.S. defense.

- The company’s advanced packaging techniques maximize chip functionality, reducing space and power consumption for vital defense technologies.

By Rachael Tiehel

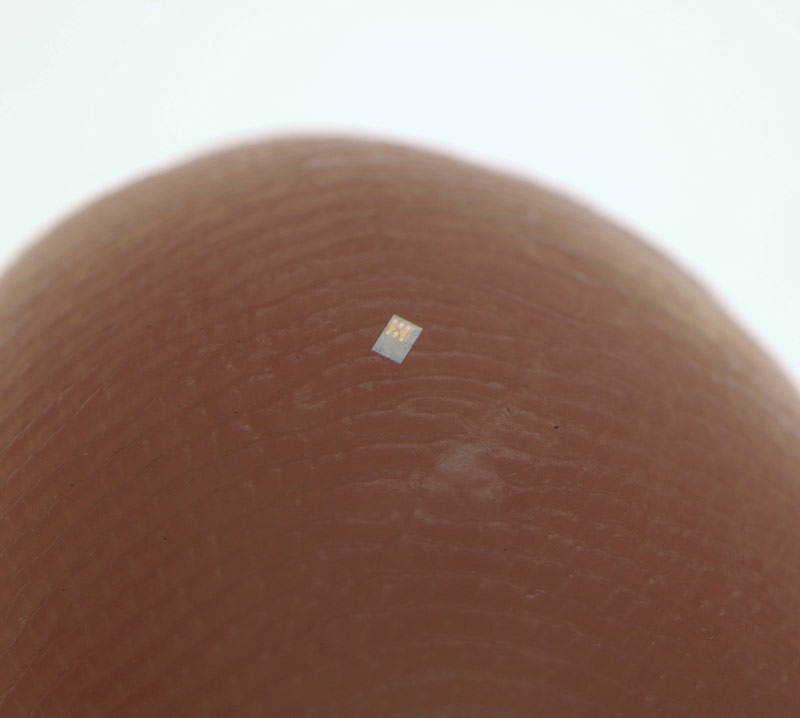

Deeply embedded inside fighter jets, radars, and satellites, are semiconductor chips, also known as microelectronics, performing essential functions ranging from signal processing to control logic. These components execute critical jobs that allow each system to sense, process, and respond to threats —and they must work flawlessly, every single time.

Though the microchip is tiny, it is the invisible force and heartbeat of every mission.

Northrop Grumman proudly manufactures and procures millions of these microscopic heroes, including the world’s fastest microchip, in the United States every year, with plans to expand our domestic capabilities and partnerships. Investing in U.S.-based microelectronics manufacturing enables us to better secure our products and, consequently, the warfighters who rely on them.

“With our deep end-to-end knowledge and manufacturing capabilities, we can deliver the right chip, with the right capability to the right mission, every time,” said Robert Mendoza, operations manager of the microelectronics manufacturing facility in Redondo Beach, CA. “With our extensive background working with these technologies, we have perfected ways to add a broad range of functions to support our nation’s military and commercial needs.”

Essential Microelectronics are the Invisible Backbone of Modern Defense Systems

Unlocking Semiconductor Potential: From Wafer to Chip

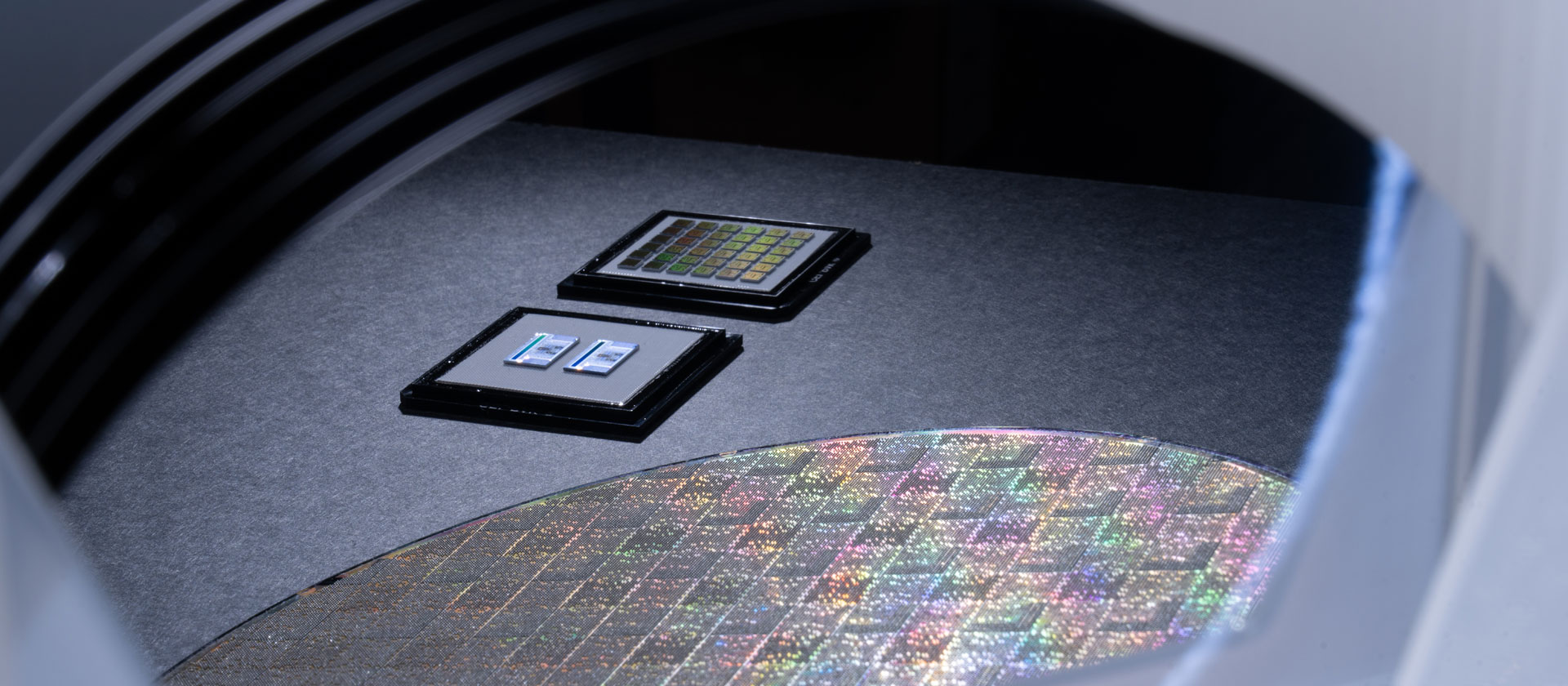

All chips start as semiconductor wafers, typically silicon or compound semiconductors such as gallium arsenide and indium phosphide. To create compound wafers, a very thin layer of highly tailored semiconductor materials is grown, atom by atom, to enhance functionality.

Boasting access to over 800 diverse materials, Northrop Grumman is one of the few microelectronics manufacturers worldwide that offers such extensive and readily accessible resources.

Fabrication Process

Once the wafer is made, it undergoes a fabrication process to create the unique devices each chip needs. This includes deposition, photolithography, and etching, repeating the cycle many times to get the necessary features. Once completed and tested, chips are sliced from the wafers using diamond saw blades or lasers and moved on to the next step of their life cycle.

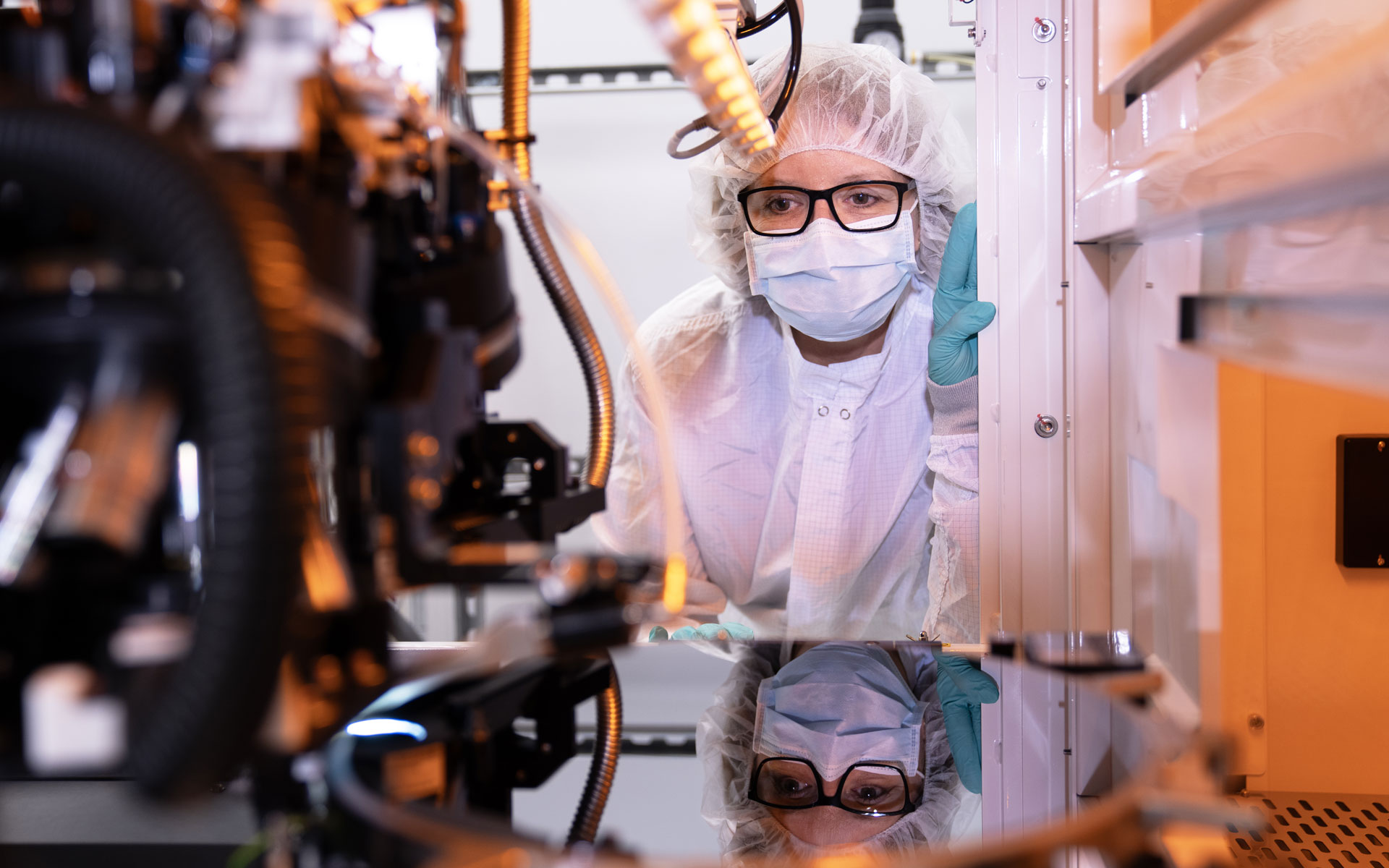

“Fabricating wafers is like baking a tiered cake — each layer uses different recipes and ingredients, and variables like temperature and time can affect the texture, taste, or look of the cake,” said Vicky Zheng, a process integration engineer at Northrop Grumman’s Baltimore microelectronics manufacturing facility.

That cake-baking takes many skill sets to complete each step and create a worthy product. For decades, our engineers have perfected the manufacturing process - and they are continuing to innovate and advance new ideas to create microchips for any mission.

Pioneering Advanced Packaging: Maximizing Performance and Efficiency

Advanced packaging integrates multiple chips with different properties and functions into a single, advanced solution. Think of building blocks stacked in ways that create a tower of power and performance, with each piece contributing to the end system.

“These 3-dimensional chip-stacking methods allow our products to do more, faster - while taking up less space and using less power. It’s critical technology,” said Brittany Battaglia, Advanced Packaging Program Manager.

Northrop Grumman has one of the few U.S.-based advanced packaging facilities, offering services that 98% of the chipmakers in our country need to source internationally.

Committing to Domestic Manufacturing: Ensuring Supply Chain Security

Much of the semiconductor industry relies on Taiwan as a crucial part of the supply chain, which poses a risk due to the impending threat of China. Investing in U.S.-based semiconductor and microelectronics manufacturing ensures supply chain security and strengthens domestic innovation. Northrop Grumman programs and our external defense and commercial partners will benefit from having more U.S manufacturing of semiconductor technologies.

To support American manufacturing, Northrop Grumman has three government-accredited manufacturing facilities across Maryland, California, and Florida, providing secure and protected places to build microelectronics. Expansion efforts are expected to quadruple chip production by 2030, helping us to employ thousands of hard-working Americans, enhance local economies, and build life-long careers. By advancing U.S. semiconductor solutions and capabilities, Northrop Grumman is powering the future of American defense.

Explore how Northrop Grumman is shaping the future of microelectronics and how you can get involved with career opportunities.

Recommended Stories

We mean it when we say anything is possible at Northrop Grumman – and our colleagues are proof of this. With the immense scale and scope of our business, you can shape your career journey with diverse roles and experiences that expand your expertise, feed your curiosity, and fuel your passion.

We are proud to share the stories of our colleagues to inspire future generations.