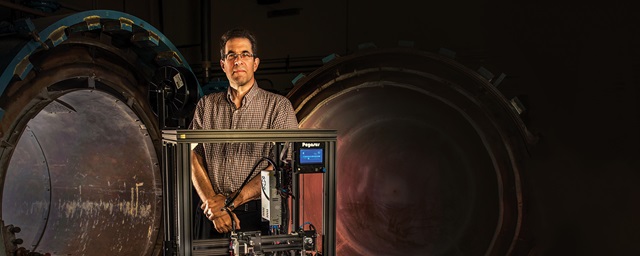

Using an additive manufacturing technique, a team of current and former Northrop Grumman employees developed a revolutionary prototype 3D printer with a fiber-reinforced composite 3D printed panel. This Bethpage, New York-based team of Jerry Nardiello, John Crawford, John Madsen and now-former teammate Robert Christ was awarded a patent for a composite 3D printing process and device. It focuses on a fused filament fabrication method for depositing long-fiber reinforced materials. First filed on December 8, 2015, the patent was granted January 8, 2019; it’s one of the newest ways to create advanced composite parts for the aerospace industry.

Significant Strength in 3D Printing

Fiber remedies plastic parts that are not reinforced properly. 3D printers often print weak plastic materials. However, using Nardiello and Madsen’s process, fiber reinforcement turns a flimsy piece of plastic into a high-strength, high-performance component.

“We’ve developed a prototype to show it can be done,” Nardiello says. “We’re making 3D printed parts that have significant strength compared to your traditional plastic 3D printed parts.” The team is also working to make the process more affordable.

“We’re trying to bring that high performance into the less expensive 3D printing process,” Nardiello adds. “When you’re making low-rate production, as we do in aerospace, [it] has some real advantages.”

Madsen and Nardiello join engineers from across the corporation to share ideas about this type of breakthrough. “All the sectors within Northrop Grumman do 3D printing and composite parts,” Madsen says.

“Although this particular patent we developed is patent for a certain part of Northrop Grumman, it’s going to hopefully have an impact on all the sectors,” he adds. “We have 3D printed parts in space, in the air and on the ground. It’s really something that’s grown by leaps and bounds at Northrop Grumman and in the industry as a whole.”

Of at least a half-dozen 3D printing processes, depositing long-fiber reinforced materials is a very specific type indeed, according to Nardiello. “There are a lot of questions asked of the inventors during the process to make sure the patent is unique,” he says.

Aerospace Applications

Their patented process employs a technique called additive manufacturing, where a part is built up or reinforced layer by layer.

“This reduces waste so it gives tremendous cost benefits,” Madsen explains.

How did team members come up with the concept? With one in their ranks who works on cars and two others who work on musical instruments, it’s a band of tinkerers.

Nardiello built a 3D printed guitar, and all four teammates thought about how to reinforce its weak plastic neck.

“We realized that it (the concept of reinforcing plastic with fiber) probably had applications in the aerospace world,” Madsen says. “I still quite often 3D print things for myself at home.”

In addition, Nardiello created a robot using this technique for Steve Engel, a retired Northrop Grumman fellow, as a test bed for a software system in collaboration with Columbia University.

Thanks to this new patent, Northrop Grumman can now develop lighter, more complex structures in less time, while generating less waste. Parts are ready in days or weeks rather than months. “It will enable [Northrop Grumman] to very rapidly build parts for prototyping,” Madsen says.

MORE ABOUT ADDITIVE MANUFACTURING AT NORTHROP GRUMMAN

Watch: Additive Manufacturing for Hypersonic Applications >

Watch: DMLS – Additive Manufacturing Innovation at Northrop Grumman >

Life at Northrop Grumman: Recent Stories

Shape your career journey with diverse roles and experiences that expand your expertise, feed your curiosity, and fuel your passion.

Life at Northrop Grumman: Archived Stories

It takes every one of us to make the impossible a reality. See what life is like at Northrop Grumman.