The Innovation Technology Paradox

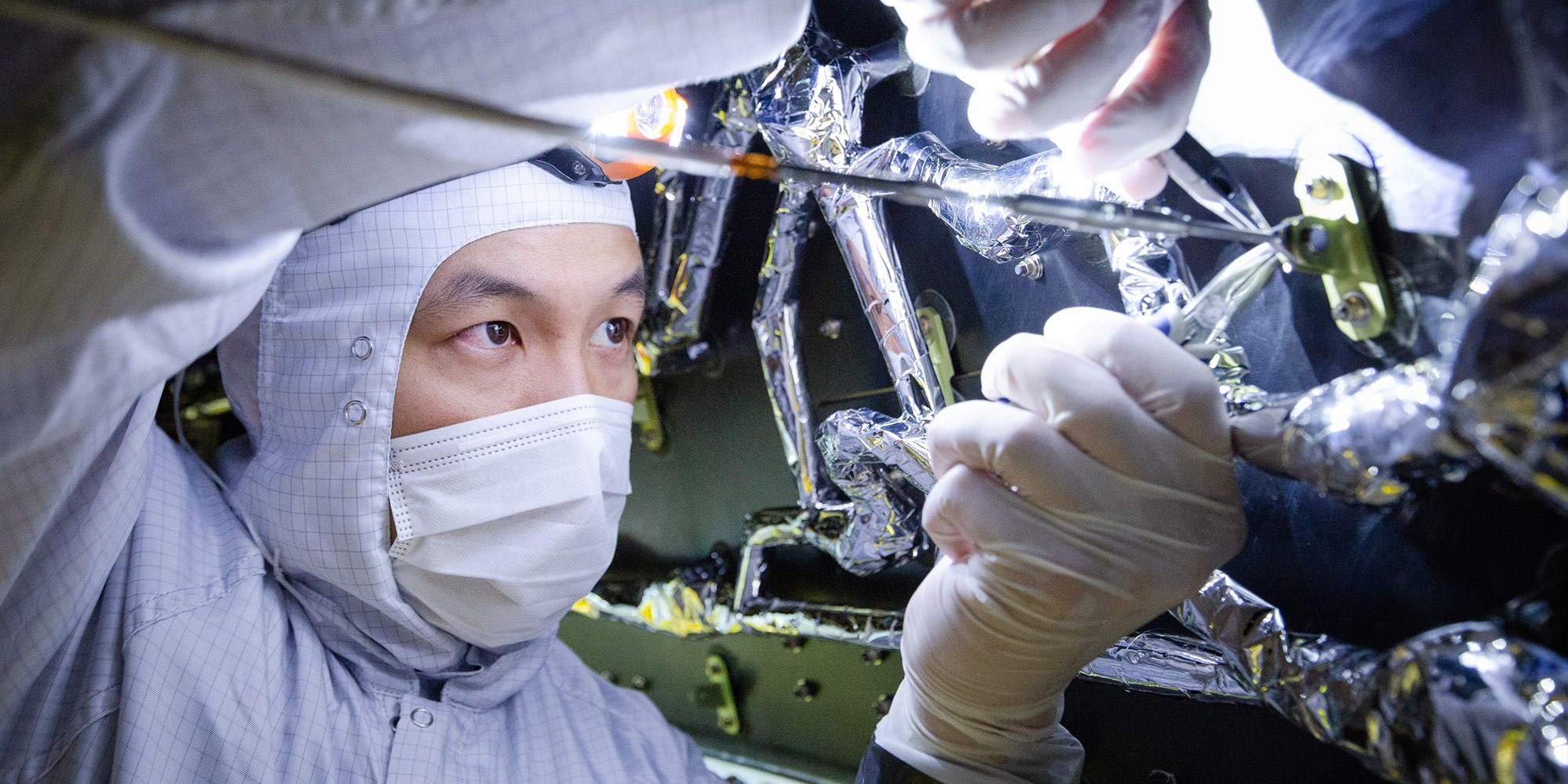

Launching Solutions into Space

By Kelly McSweeney

Innovation requires a balance between creativity and taking risks; there must be a pragmatic, structured approach to introducing new ideas, especially within a larger company that may be perceived as bureaucratic. Striking that balance creates a common dilemma: embracing innovation technology without disrupting current operations.

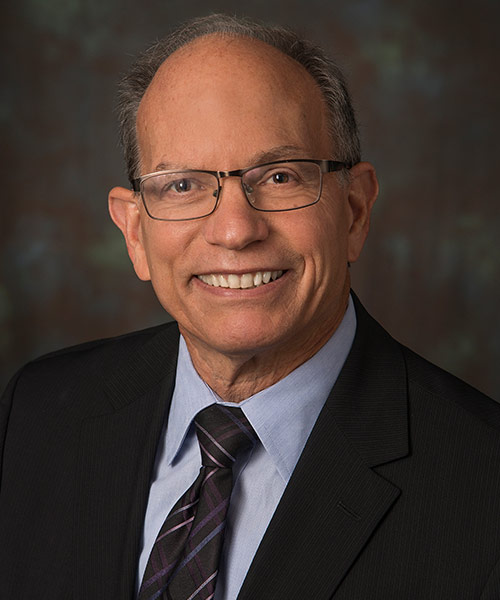

“I call it the technology paradox,” says Dr. Ed Silverman, a Northrop Grumman Fellow. “In order to be efficient, you want to optimize your current operation, but in order to survive, you also have to incorporate disrupted ideas.”

In his 35-year career, his new ideas have led to 20 patents and six technologies adopted into space vehicles. He’s developed creative solutions to improve space vehicle components such as composite fittings, lighter-weight thermal designs, multifunctional adhesives, stable reflectors, lighter-weight cables and more recently, a removable thermal gasket.

He recently audited his new technology projects over his career to find the “secret sauce” that made them successful.

When Silverman analyzed his past victories against the technology shortfalls that didn't make it to adoption, he noticed a common theme: projects were more likely to succeed if he brought in the designers, product managers, and leaders earlier in the innovation process.

He further refined his process into three main steps: creativity, prototyping and diffusion.

Step 1: Creativity and Creating Value

The first step is to create value that someone is willing to pay for. Simply having an idea for a new technology doesn't mean it will have real world applications. Even if it technically improves prior technology, more factors are at stake.

Twenty years ago, Silverman was working on a composite manufacturing process for an avionics chassis that would technically be lighter than the aluminum used for space vehicle components at that time. Creatively, this next-gen tech demonstrated superior test results, but was rejected due to its high manufacturing costs. Going forward, he would bring the product champions into the process right away to overcome resistance during the early creative stages.

Even if the technology falls short, creative efforts can pay off with some patience. Silverman has been searching for a new thermal gasket for decades. He wanted to solve a problem in space vehicles that would make it easier to fasten and cool electronics— but they normally use adhesive gaskets that are hard to remove. He found a contender 20 years ago, but it turned out to have contamination issues.

"Sometimes, you need to put the technology concept on the shelf and wait for the right timing," he says.

Silverman continued the search (while quickly eliminating any gasket that had similar contamination issues) until recently, when he found the solution at an innovative company growing carbon nanotubes on aluminum foil.

"A reason for this gasket's success is because it's going to save money," he says.

While the previous adhesive-based gaskets required many hours of labor due to its special curing process, the new version is removable and can be handled without curing.

Dr. Ed Silverman

Northrop Grumman Fellow

Step 2: Prototyping Innovation Technology

At the prototyping phase, there needs to be verification that the new idea actually works and is valuable to the company. Many ideas end at this stage because the technology simply doesn't work. For the innovations that make it through design and testing, one can continue building an informal network of support within the organization. Not only will this help to promote the idea, but it will also help determine whether the technology can meet the specifications that adopters will eventually require.

Additionally, the technology has to be producible beyond the prototype. When Silverman was developing carbon nanotube cables, for example, his team reached out to the manufacturer early in the process to make sure it could actually be produced.

"A key ingredient to ensure success is working with the supplier and getting their buy-in," he says. “Interestingly, all of my successful technology projects depended on having a pioneering manufacturer as part of the team.”

Step 3: Diffusion to Adopters

The last step, transferring the product to potential adopters, is the most important and the most difficult to achieve. "It's not sufficient just to come up with a creative idea and expect it's going to diffuse into the end application," Silverman says.

By trial and error, Silverman has learned to work on technology diffusion throughout the creative and prototype steps, not just at the end. That way, by the time he achieves a successful design, he has already fought resistance and gained support within the organization. It's crucial to get the program managers and executives on board early. Sometimes agents outside the organization, such as the government, are even more important in diffusion than champions inside the organization, for they add real legitimacy and even funds to the idea.

"The innovator has to go out and promote the technology, get the right people on the team, get the funds to develop the prototype to verify the value and then get the manufacturing in place to diffuse it to the adopters," Silverman explains. “Overall, gathering support throughout all of the innovation phases plays a large role in determining whether an idea gets adopted.”

Technology innovation disrupts the stable operation at an established company. But by fostering a culture of innovation, the disruption pays off in longevity and growth.

More innovation stories

Read all stories about advanced technology and innovation >>