The Beginning of Beyond

Artemis Rocket Testing Helps Propel the Next Giant Leap in Space Travel

By Brooks McKinney, APR

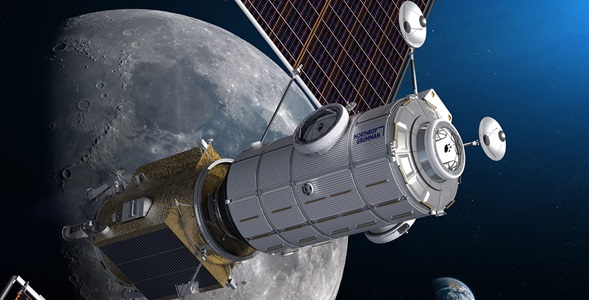

An uncrewed version of NASA’s new heavy-lift Space Launch System (SLS) will be the first of several Artemis missions that will break boundaries and set records, returning us to the moon and ultimately preparing us for unprecedented exploration of deep space.

The SLS is the most powerful rocket ever built, with 8.8 million pounds of thrust, and is largely made possible by Northrop Grumman’s solid rocket boosters (SRBs). The five-segment SRBs will provide 75% of the thrust required to lift SLS off the launch pad and ultimately carry astronauts farther into space than ever before.

All of that power requires special attention to safety and performance. Building these massive boosters is a challenge unto itself, and testing them means integrating a host of cutting-edge techniques that borrow from the emerging field of civilian space.

Re-Boosting Space Exploration

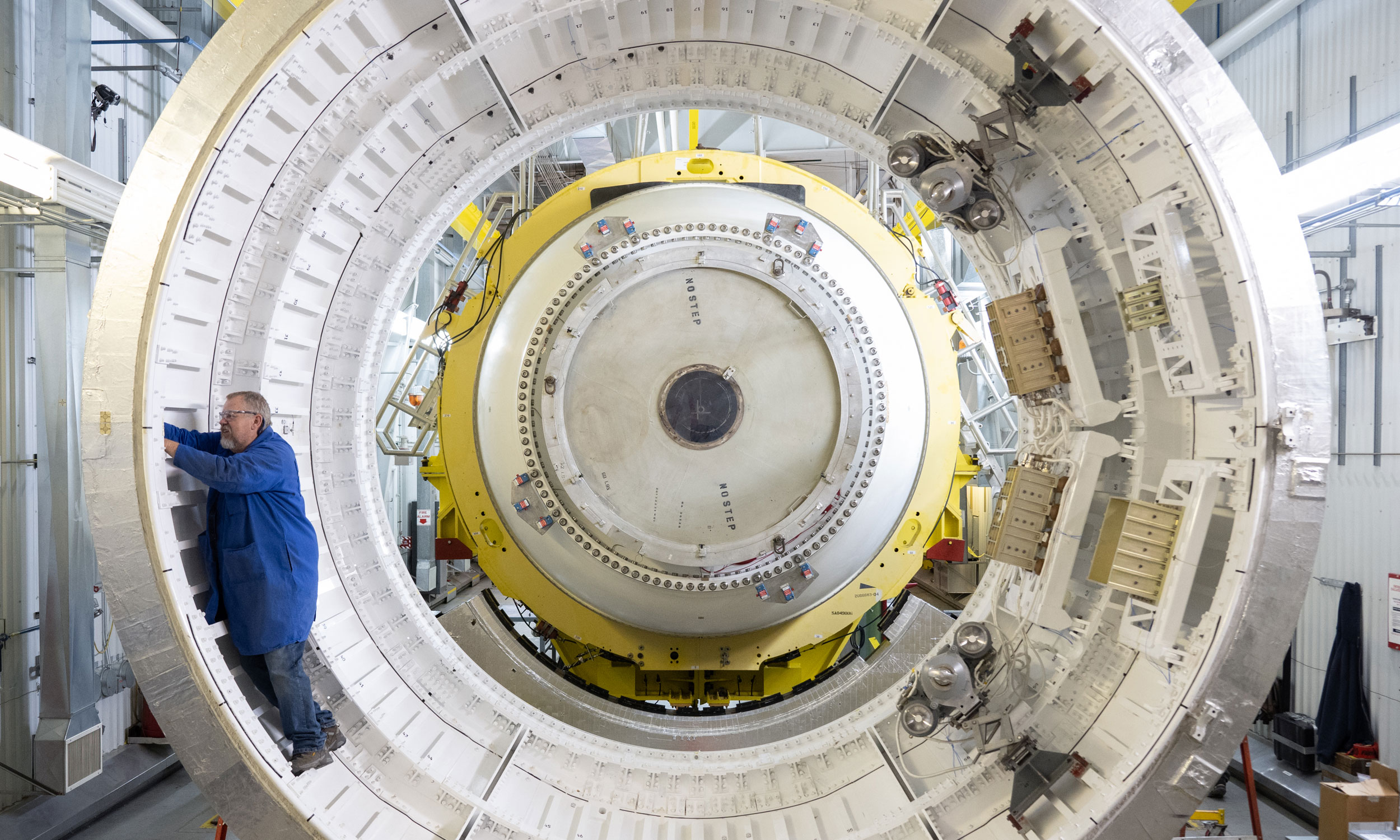

A solid rocket booster is a large, solid propellant motor capable of providing incredible amounts of thrust with a relatively simple design. They can stand almost 150 feet high and weigh more than 1 million pounds.

Each new SRB is actually a remodeled, refurbished rocket that began life as a four-segment SRB produced by Northrop Grumman for NASA's space shuttle program. Paul Karner, Northrop Grumman's senior program manager for SRBs' avionics and controls explained that many commercial rocket companies are now using reusable rockets to reduce the cost of access to space. The Northrop Grumman team is using a similar strategy to support the Artemis program.

With that approach, the team does rigorous and complete testing of the SRB in multiple stages up until launch.

"It takes us about 18 weeks to mate the five segments into an SRB," explained Mahmood Akhavan, a solid rocket motor testing specialist for the company's Propulsion Systems Business Unit in Promontory, Utah. "The process culminates with a full-scale static test of each fully assembled SRB on a horizontal test stand."

Assembling the Rocket

When SRB static testing is complete, the boosters are disassembled and shipped as individual segments via railroad from Promontory to Kennedy Space Center in Florida. There, they are reintegrated with the SRBs' forward and aft skirts, nose caps and thrust vector control system in NASA's iconic Vehicle Assembly Building (VAB), a process that takes about five months.

The VAB serves as the final assembly point for the SLS, including attachment of the SRBs to its core stage and the stacking of the SLS's upper stage and Orion crew vehicle on its core stage.

Once the assembly of the SLS is complete, the NASA/contractor test team conducts several functional checks in the VAB to ensure that all SLS subsystems — think flight computers — are operating correctly and communicating with each other.

Taking Cues from Commercial Spaceflight

The final and perhaps most important prelaunch test of the SLS is the wet dress rehearsal, a comprehensive, all-hands-on-deck "dry run" designed to mimic every activity that occurs on launch day except actually lighting the SRBs and launching the rocket.

Surprisingly, the wet dress rehearsal is not standard prelaunch practice for NASA but is increasingly common for commercial spaceflight, according to Karner.

Since many of these commercial engines have flown on multiple missions, it's especially important to do this performance and quality check before every launch. The Northrop Grumman team is following a similar testing method of the “remodeled, refurbished” solid rocket boosters to support this mission.

Karner emphasized that prelaunch rocket tests are designed to make the launch process as safe as possible. As space travel becomes increasingly common, teams will test, learn and evolve their testing practices.

"Rocket testing will never be without risk, but as we get a better sense of which tests need to occur before every launch and which ones don't need repeating, it should become shorter and more routine," he said.

The Artemis program will achieve several historic firsts for our world, including landing the first woman and first person of color on the moon by 2024. New technology like what’s being used for Artemis will enable exciting new achievements in space exploration for decades to come, like lunar habitation and, eventually, travel to Mars and beyond.

More Innovation Stories

Read all stories about advanced technology and innovation