Pioneering Technology

As an early pioneer with 3D printing technologies, Northrop Grumman has been at the forefront of evolving AM – from prototyping to deliverable products. We have integrated thousands of AM polymer parts into air and space systems to date. Our accomplishments include:

- The first metallic AM part flown on a DoD aircraft—a titanium component on X-47B in 2011

- A titanium metallic AM part launched on a spacecraft

- On-going certification of multiple components across aeronautics and space programs

Northrop Grumman continues to define what’s possible with AM by pushing to expand available material systems and apply AM to both novel and more critical applications.

| Material Family | Processes | Space Product Applicability |

|---|---|---|

| Titanium | Electron Beam Powder Bed Fusion, Laser Powder Bed Fusion | Structures and subsystem products |

| Aluminum | Laser Powder Bed Fusion | Structures and subsystem products, Thermal Products, Electrical Products |

| Cobalt, Nickel, Other | Laser Powder Bed Fusion | High-Temp Products |

| Low Expansion Alloy | Laser Powder Bed Fusion | Payload Products |

| Silicon Carbide | CERAPRINT™ | Payload Products |

| Copper | Electrochemical | Thermal Products, Electrical Products |

| Titanium | Automated Stir Friction Welding, Wire Directed Energy Deposition | Launch Vehicles and Motors, Space Vehicle & Payload Products |

| Aluminum | Automated Stir Friction Welding, Wire and Powder Directed Energy Deposition | Launch Vehicles and Motors, Space Vehicle & Payload Products |

| Steel | Wire Directed Energy Deposition | Tooling, Ground Equipment, Launch Vehicles and Motors |

| Rigid ESD-Safe Polymers | Laser Powder Bed Fusion, Material Extrusion | Secondary/tertiary structures products, covers, guards, tooling, rapid prototypes |

| Elastomeric ESD-Safe Polymers | Material Extrusion | Protective cases, ground equipment, structural dynamics products |

| Neat Rigid Polymers | Material Extrusion | Tertiary products, tooling, rapid prototypes |

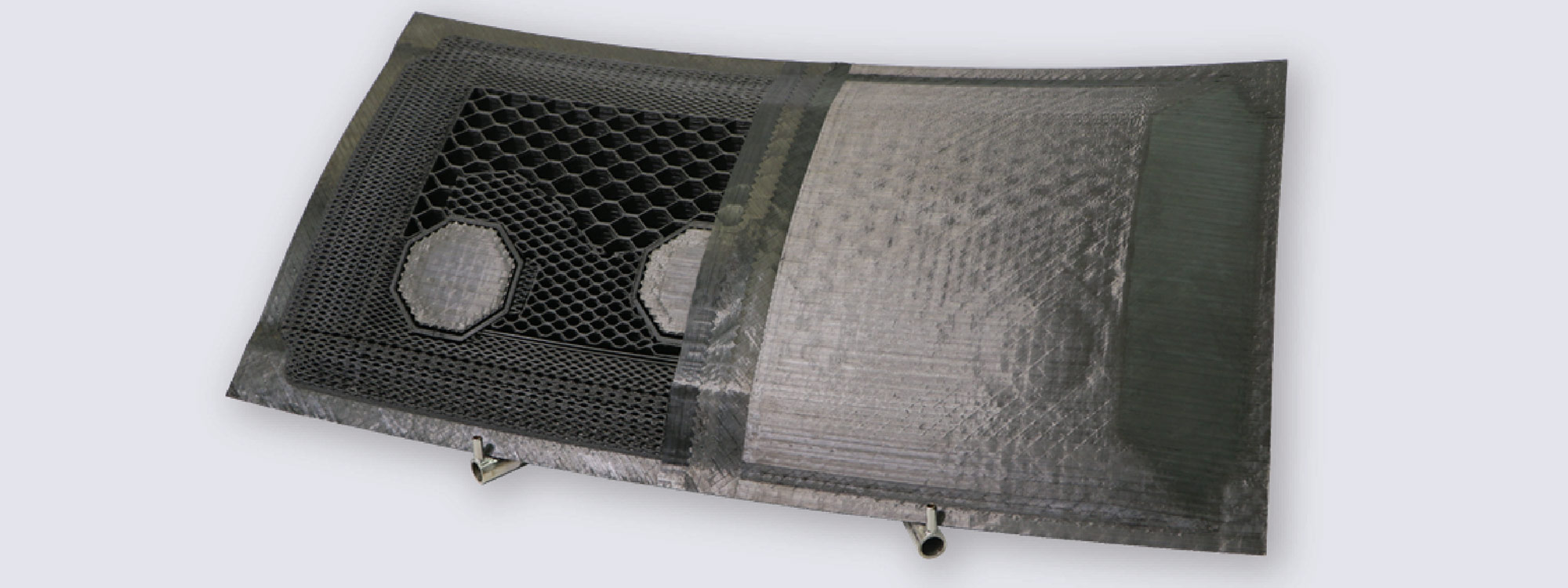

| Continuous Fiber Composites | Scalable Composites Robotic Additive Manufacturing (SCRAM) | Structures and Subsystem Products, Payload Products, Other |