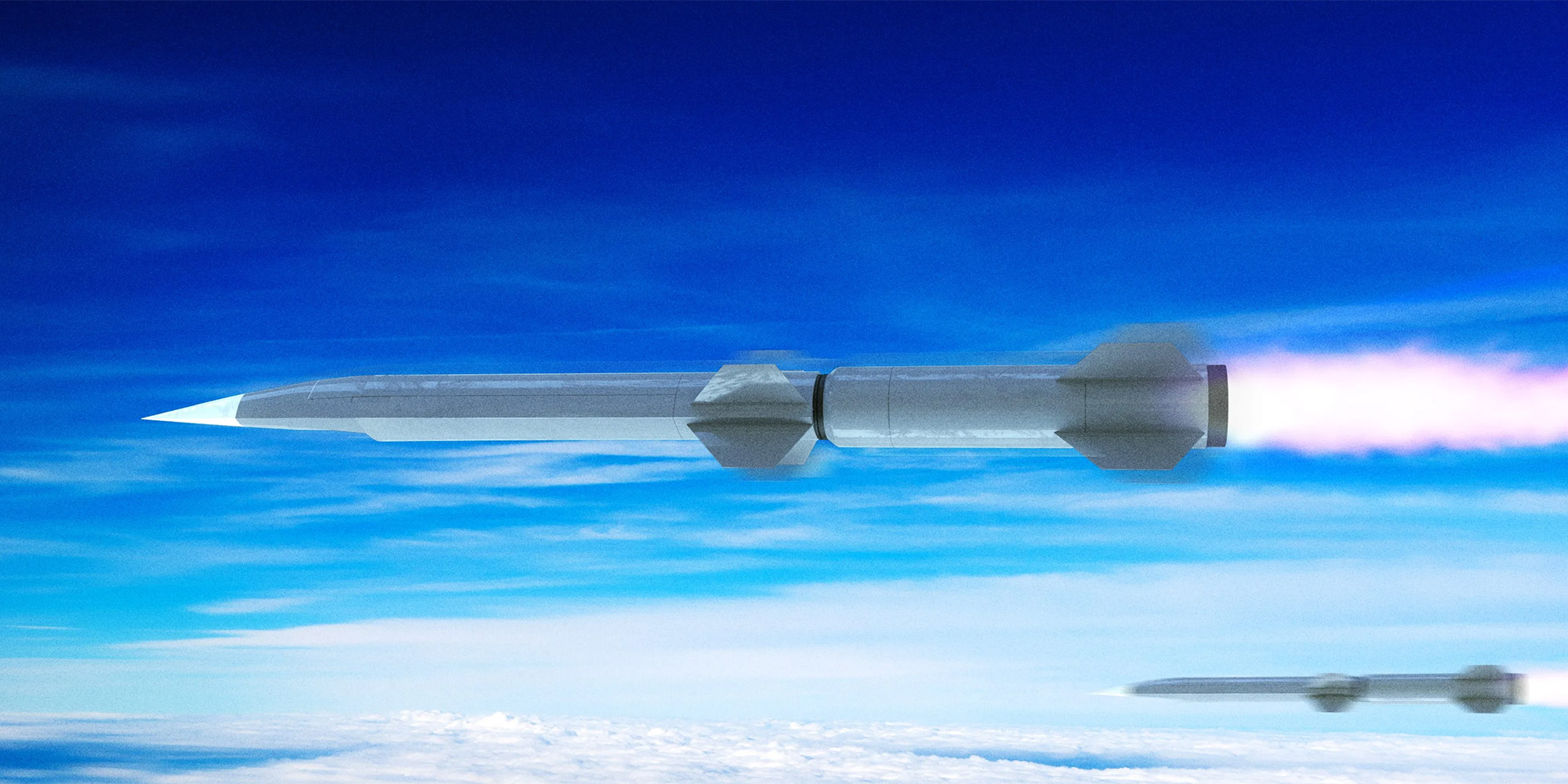

Hypersonics Breakthroughs Are Boosting Range, Speed and Survivability

The fastest motors are getting more flexible, more cost-effective and even faster.

The Bell X-1 rocket, with Maj. Chuck Yeager in the cockpit, got the world talking about supersonic flight when it broke the sound barrier on October 14, 1947. Less than two years later, on February 24, 1949, a U.S. WAC Corporal sounding rocket became the first object of human origin to go hypersonic – more than Mach 5, or five times faster than the speed of sound.

We’ve always felt the need for speed. And, after more than half a century, there continue to be breakthroughs in hypersonic aircraft and missile development.

Hypersonic systems present a complex engineering challenge. They require careful thermal management; there are sophisticated power needs involved; and continuing calls for miniaturization – to get smaller and lighter as well as faster – further complicate the picture.

Pushing Hypersonics Forward

U.S. Department of Defense interest in hypersonics has accelerated as the United States faces developing threats from near-peer competitor nations. To prevail in the battlespace of the future, the U.S. military and allies need systems that are both higher-performing and affordable.

With the latest developments in ramjets, scramjets and advanced solid rocket motors, the fastest missiles in the world are getting even faster and more capable. They're also more flexible, cost effective and survivable than ever. Here are some of the operationally ready technologies driving America's hypersonics resurgence:

Ramjets

Rocket engines need oxygen. If they can get it from the atmosphere there is no need to carry heavy onboard oxygen tanks. “Air-breathing” engines can trim the weight and complexity of an aircraft or missile.

A ramjet engine is a key component of air-breathing systems. Ramjets draw in air for combustion using just the forward motion of the missile, doing away with the compressors and turbines of traditional jet engines to achieve exceptional speed with fewer moving parts. Recent advances in miniaturization allow more flexible form factors for ramjets, which today can be delivered within a range of size constraints to meet specific military needs.

Scramjets

A variant of the ramjet, the supersonic combustion ramjet – or scramjet – operates at even higher speeds. Advanced materials and sophisticated modeling are making scramjets ever more efficient, and of particular interest to developers of air-breathing hypersonic missiles and interceptors.

In September 2021, in partnership with Raytheon Missiles & Defense, a Northrop Grumman scramjet delivered the thrust for the first successful flight test of a scramjet-powered Hypersonic Air-breathing Weapon Concept, or HAWC, for the Defense Advanced Research Projects Agency and the U.S. Air Force.

Advanced Solid Rocket Motors

Hypersonic performance requirements are also pushing improvements in solid rocket motors.

New propellant formulations deliver greater thrust, and more propellant can be packed into a given volume than in the past. Improved nozzle types are increasing performance without all the thermal barrier coating required by older nozzles.

Sophisticated Approaches

Advanced engineering processes and sophisticated approaches to the hypersonic problem are helping drive these advances. Additive manufacturing – a transformative approach to industrial production – makes hypersonic solutions more cost-effective. Advanced materials allow engineers to develop systems that can operate at higher temperatures. Sophisticated modeling and simulation capabilities speed development processes while lowering costs. And advances in computational fluid dynamics enable designs that weren’t possible 20 years ago.

Northrop Grumman brings a broad range of skilled experts to the table in the search for hypersonic solutions. Internal testing and other capabilities allow innovative engineers and developers to put their ideas into action.

"We bring all the disciplines together — the power, the thermal, the performance," Gettinger said. "By modeling and designing all of that together, by viewing the missile as a single system, we're able to get a higher-performing system that can go farther, carry more, and fit into a smaller package."

The Northrop Grumman teams see even more breakthroughs in hypersonics and advanced weapon systems on the horizon.

"Soon we will be able to do things that simply weren't practical or affordable in the past," Gettinger predicted. "We'll see levels of performance that go even further than what is available today."

Media Contact

Kailen Brant

443-465-8963