The Aerothermal Research and Testing facility tests the capabilities of electronics and equipment at conditions simulating speeds up to Mach 8.

2020s

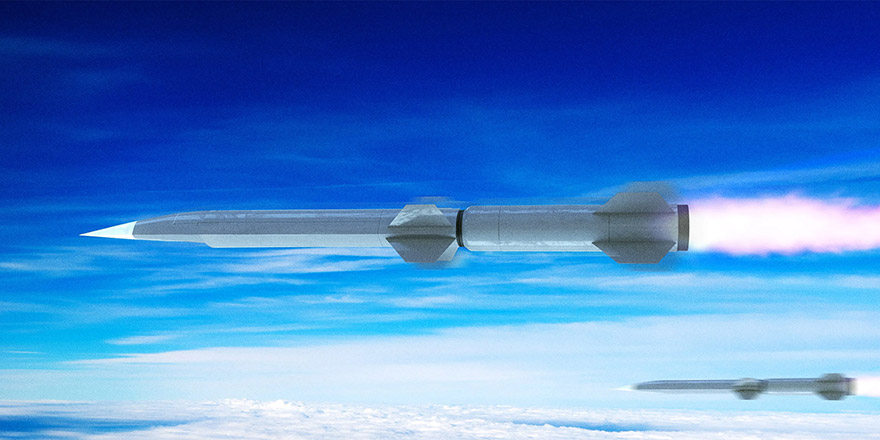

Image developed by Raytheon Missiles & Defense

2022: US Air Force Selects Raytheon Missiles & Defense, Northrop Grumman to Deliver First Hypersonic Air-Breathing Missile

2022: Second flight of the Defense Advanced Research Projects Agency (DARPA) Hypersonic Air-breathing Weapon Concept (HAWC) scramjet.

2022: DARPA’s OpFires hypersonic missile program successfully demonstrated a new mobile ground-launch system using common military logistics vehicles with a Northrop Grumman rocket motor.

2021: Groundbreaking for the new Hypersonics Capability Center at Elkton, Maryland, setting the stage for the future.

2021: First flight of the DARPA HAWC scramjet.

2020s

2010s

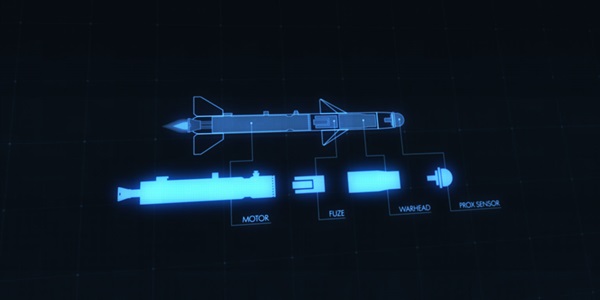

Photo credit: Northrop Grumman

2018: First test of platform scale (10X) scramjet engine at greater than Mach 4 conditions.

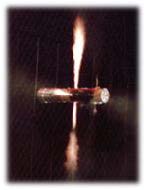

2017: First 15-minute continuous firing of a flightweight scramjet combustor.

2015: First test of additively manufactured Northrop Grumman scramjet combustor.

2010s

2000s

Photo credit: NASA

2007: First freejet test of Northrop Grumman missile scale scramjet.

GASL (a legacy Northrop Grumman company) develops low-cost scramjet flight test technique and demonstrates it with Mach 6 flight program.

GASL demonstrates gun-launched scramjet flight testing at Mach 8.

2004: The X-43 sets a scramjet speed record at Mach 9.3 using a Northrop Grumman engine.

2003–2005: NASA selects GASL as prime contractor for the NASA X-43C follow-on program.

2000s

1990s

Photo credit: Northrop Grumman archives

1993: The first solid propulsion hover test is completed on the Lightweight Exo-atmospheric Projectile (LEAP) program on a kill vehicle.

1990s

1980s

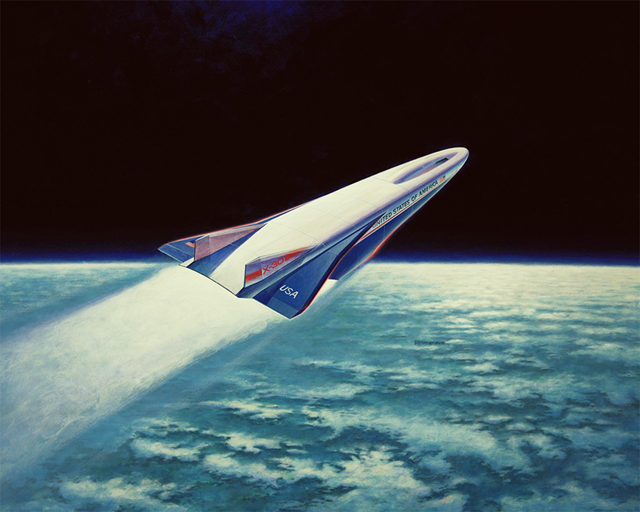

Photo Illustration credit: NASA

1985: As a key participant on the X-30 National AeroSpace Plane (NASP) program, GASL is designated “Government Associate Contractor” for the NASP Technology Maturation program.

1980s

1970s

Photo credit: Northrop Grumman archives

GASL collaborates with NASA Langley Research Center (LaRC) to continue development of scramjet technology with the “parametric engine.”

1970s

1960s

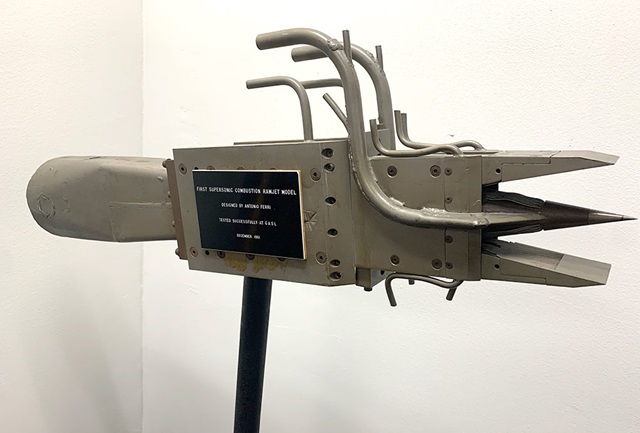

Photo credit: Northrop Grumman

Northrop Grumman supports the Titan II missile with the Stage 2 retro and reentry vehicle vernier motors (STAR 13–class motor); the Titan retro will stay in production for more than 43 years.

GASL performs first shock tunnel tests of hypersonic combustion and builds earliest-known scramjet test complex on Long Island.

Dr. Antonio Ferri designs the first successful scramjet engine; it is tested at GASL in 1961–1964 timeframe under contract to the Air Force Research Laboratory (AFRL).

1960s

1950s

Photo credit: NASA

1958: First Discoverer motors are fired in space and Project Mercury begins.

Cajun begins work on sounding rockets followed by Apache, Iroquois, Tomahawk, Sandhawk, Cherokee, and Yardbird.

Project Farside reaches an altitude of 1000 miles in 1957.

Falcon becomes Thiokol’s (a legacy Northrop Grumman company) first production program; more than 10,000 are produced at Northrop Grumman.

1955: Northrop Grumman begins work on Recruit for X-17 flights.

1951: Northrop Grumman’s Maryland facility is reactivated, with approximately 20 employees by 1953, to develop ammonium nitrate jet-assisted take-off (JATO) propellants and motors with the Air Force.

1950s