Defining Possible in the Air

Northrop Grumman is an innovative provider of proven manned and unmanned air systems.

Delivering Customer Advantage

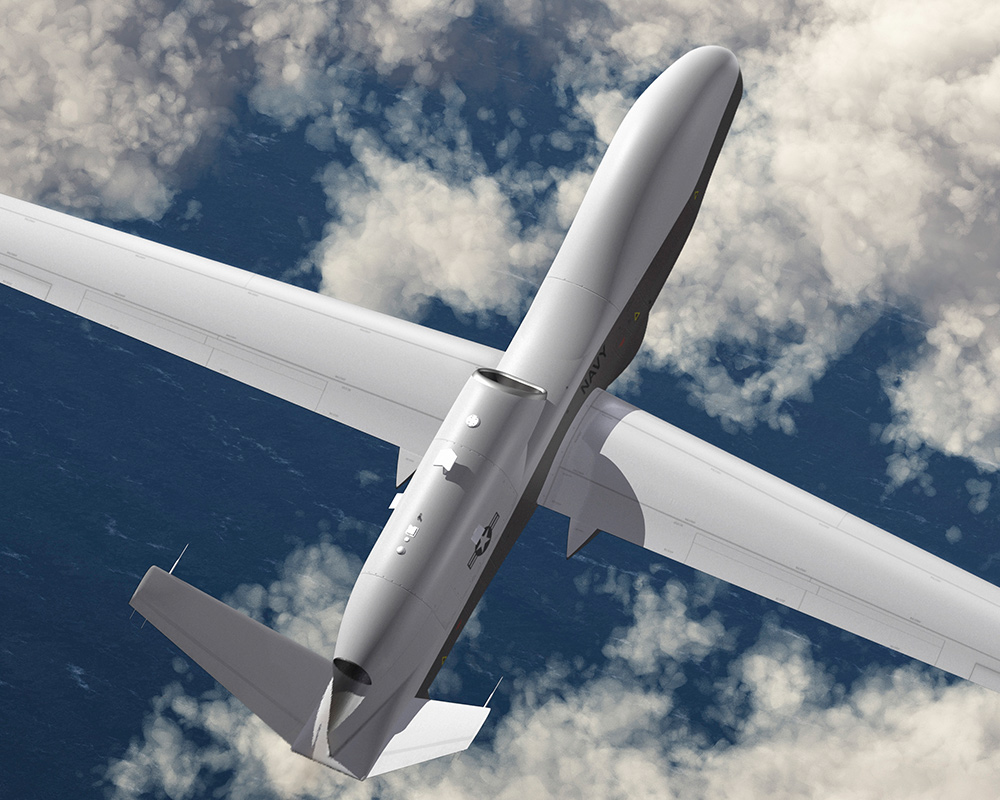

Autonomous Systems

From unmanned aerial vehicles to hazardous-duty robots, underwater minehunting systems and defense readiness targets, Northrop Grumman is a recognized leader in autonomous systems, helping our customers meet a wide variety of missions across sea, air, land and space.

Composite Structures

From fuselage parts to engine components, Northrop Grumman's lightweight, high-strength composite materials are reducing the weight, improving the performance and lowering the lifecycle cost of commercial aircraft.

Learn More

Countermeasures and Sensors

Northrop Grumman maximizes survivability by improving aircrew situational awareness via interactive management of all onboard sensors and countermeasures.

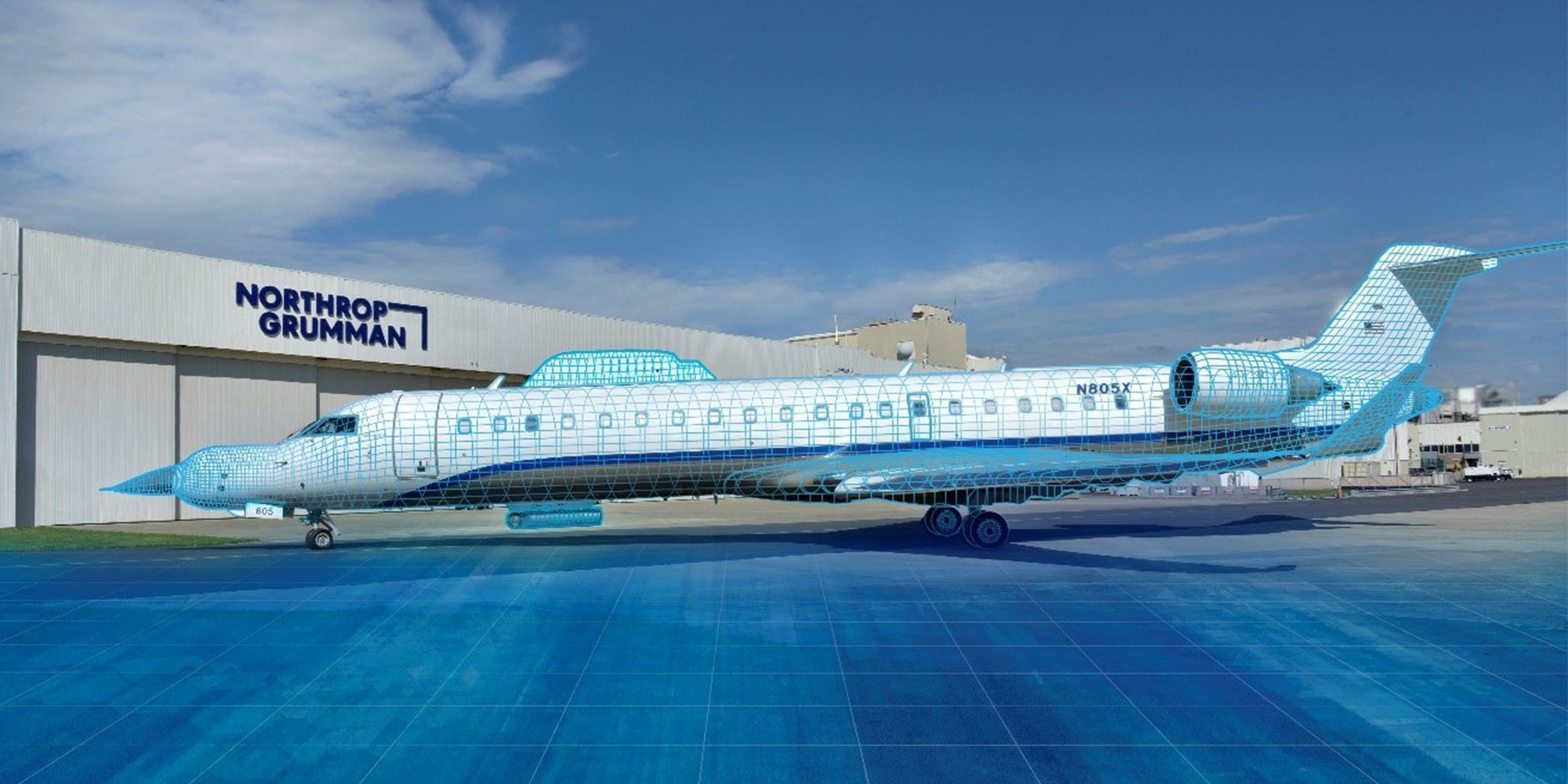

Digital Transformation

Northrop Grumman is harnessing integrated digital technologies to rapidly conceptualize, design, build, and sustain value-driven solutions.

Directed Energy

Northrop Grumman develops high-energy laser solutions to defend our nation at sea, on land, and in the air.

Electronic Warfare Systems

Northrop Grumman's capabilities in electronic warfare systems span all domains – land, sea, air, space, cyberspace and the electromagnetic spectrum.

Integrated Avionics

Northrop Grumman is your one-stop shop for integrated avionics mission solutions. Our agile, open architecture based design is adaptable and transportable to multiple platforms and missions. With our existing digital backbone for your aircraft, capabilities can be easily and rapidly added in the future. (Photo courtesy of the U.S. Army)

Logistics, Sustainment and Modernization

As a leader in logistics, sustainment and modernization, Northrop Grumman provides full lifecycle support on a wide array of aircraft, platforms, programs and weapon systems to deliver uninterrupted mission readiness, enabling mission success.

Manned Aircraft

Since our inception, Northrop Grumman has been a pioneer in the development of manned aircraft. From fighter jets and stealth bombers to surveillance and electronic warfare, we've been providing manned solutions to customers worldwide since the 1930s.

Military Aviation Systems

Northrop Grumman has a proud tradition of providing technological leadership in all aspects of military aviation and aircraft, such as manned, unmanned, targeting, surveillance, and aircraft self-protection systems that enable warfighters to accomplish missions anytime, anywhere and under any conditions.

Navigation Systems

Northrop Grumman Inertial Navigation Systems calculate direction moved over time, with a varying degree of drift, and with the use of high-precision oscillators provide continuity of time. The great advantage of the Inertial Navigation System is that it cannot be spoofed or jammed.

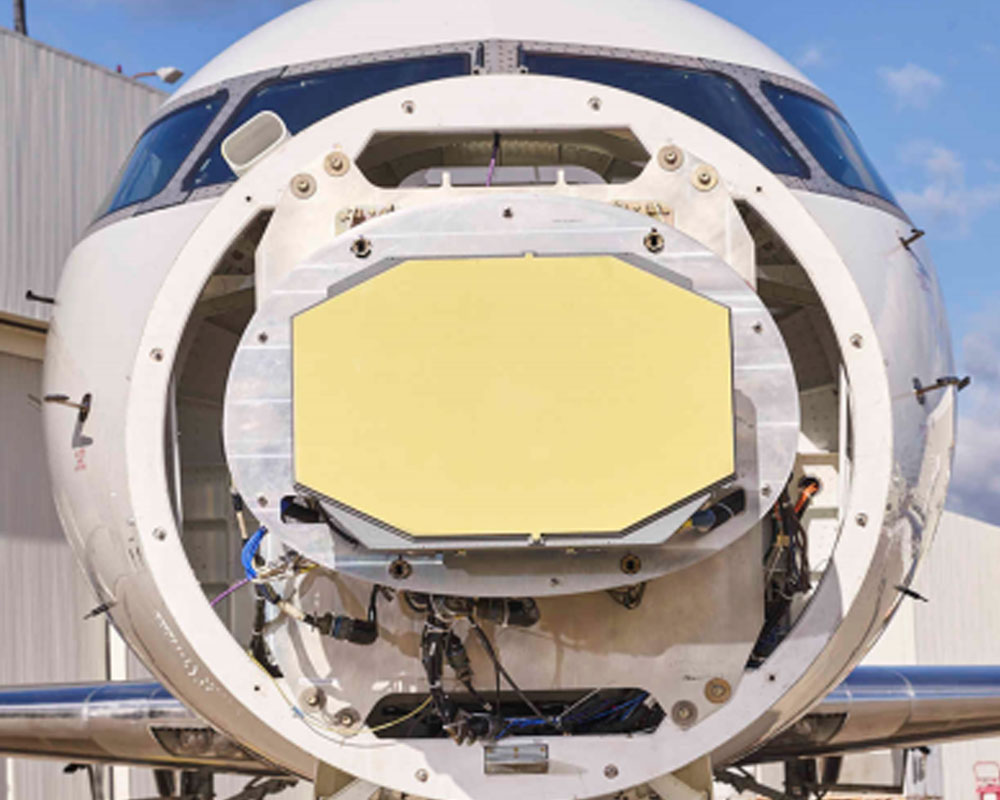

Radar Systems

Built on a wealth of design and production experience, Northrop Grumman’s active electronically scanned array (AESA) radars provide unparalleled battlespace situational awareness and air-to-air and air-to-ground superiority.

Strike

As a leader in integrated strike systems, Northrop Grumman brings world-class capabilities in system design, air vehicle design, flight controls, strategic missile systems, vehicle management systems, network-enabling technologies and survivability.

Airborne ISR

For Airborne Intelligence, Surveillance and Reconnaissance, Northrop Grumman uses advanced technology and proven engineering capabilities to provide manned and unmanned, platform and payload agnostic solutions for actionable information around the clock.

Technology and Innovation

For some, the word 'impossible' ends discussions. For us, it's a starting point.