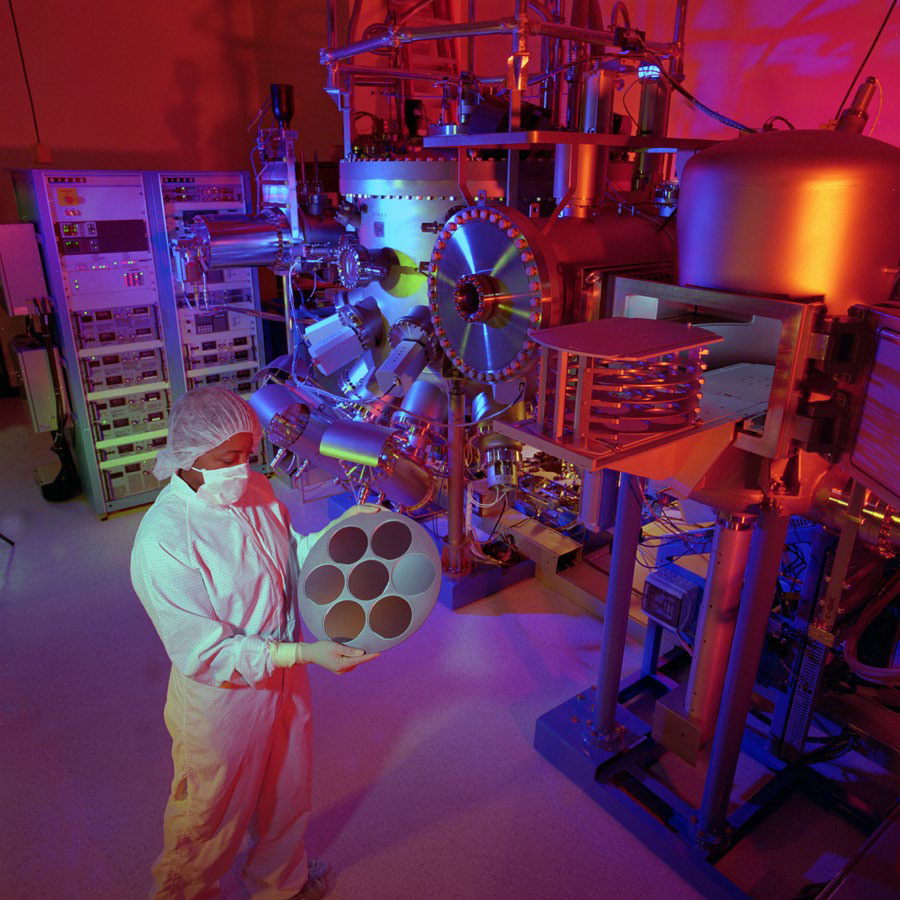

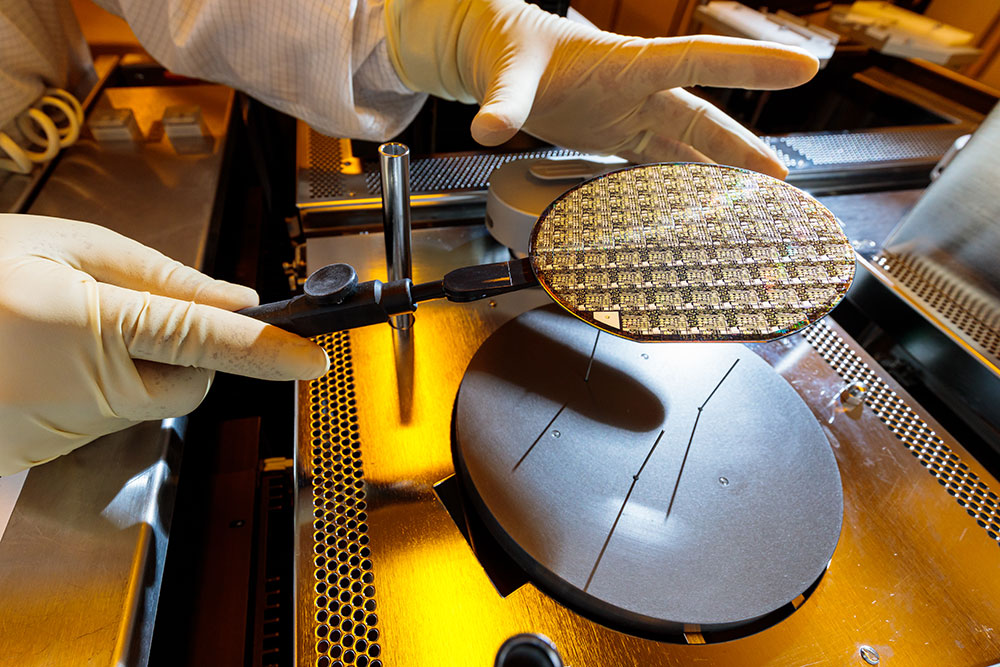

We specialize in molecular beam epitaxy, an advanced method to grow extremely pure and precisely controlled semiconductor crystals, essential for high-frequency electronic applications.

Microelectronics

Powering American defense with smaller, smarter technology.

Pioneering Microelectronics for Advanced Technology

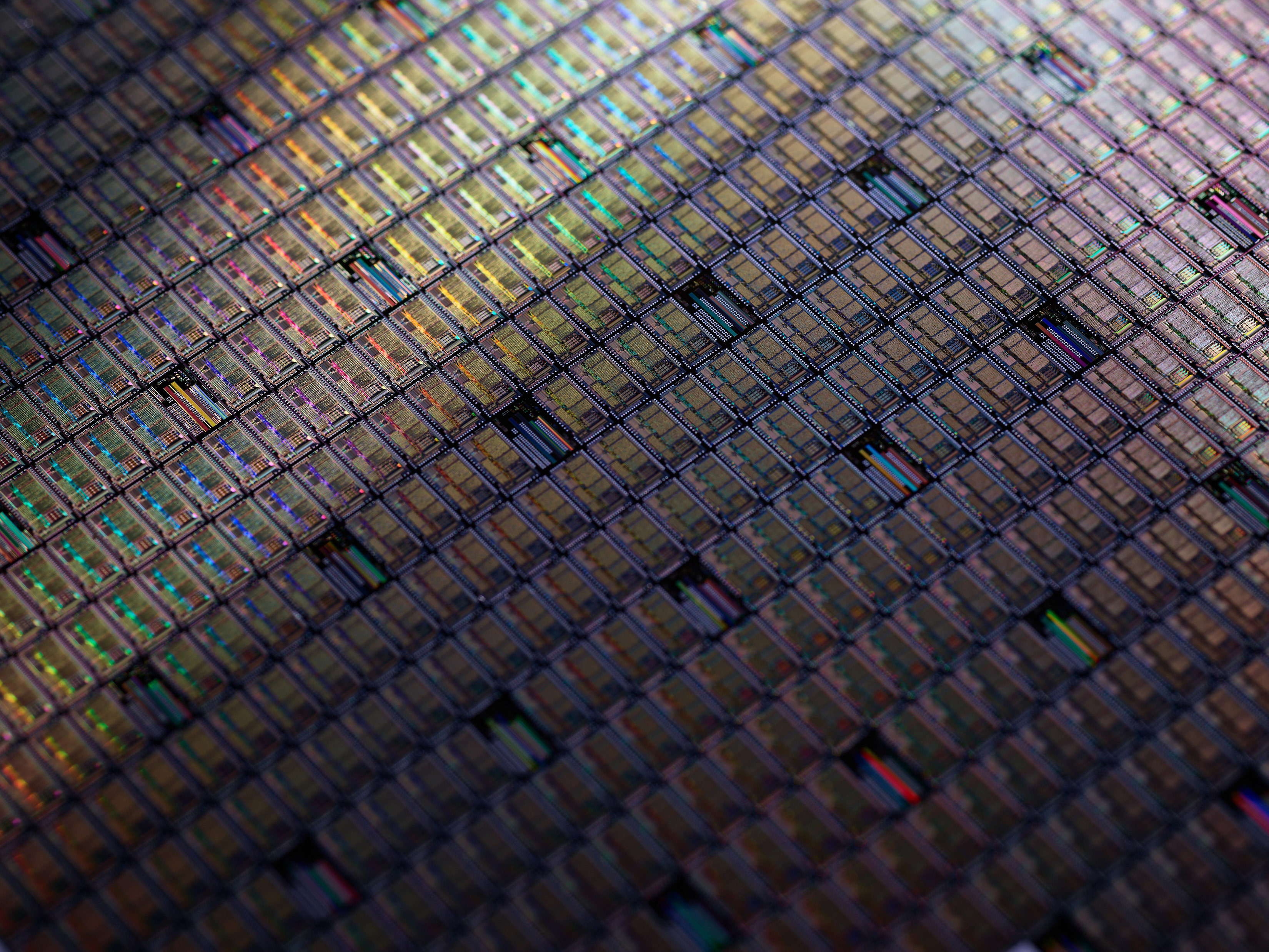

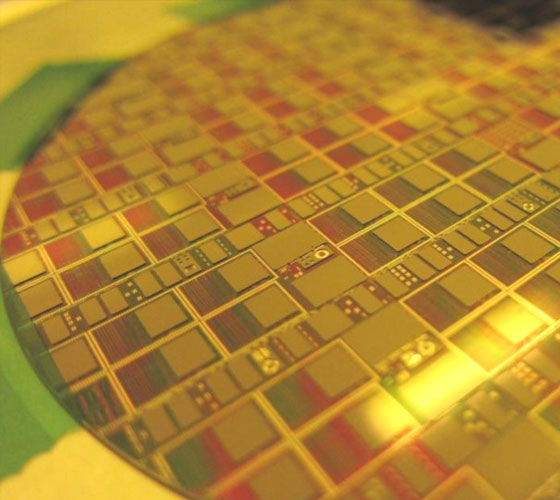

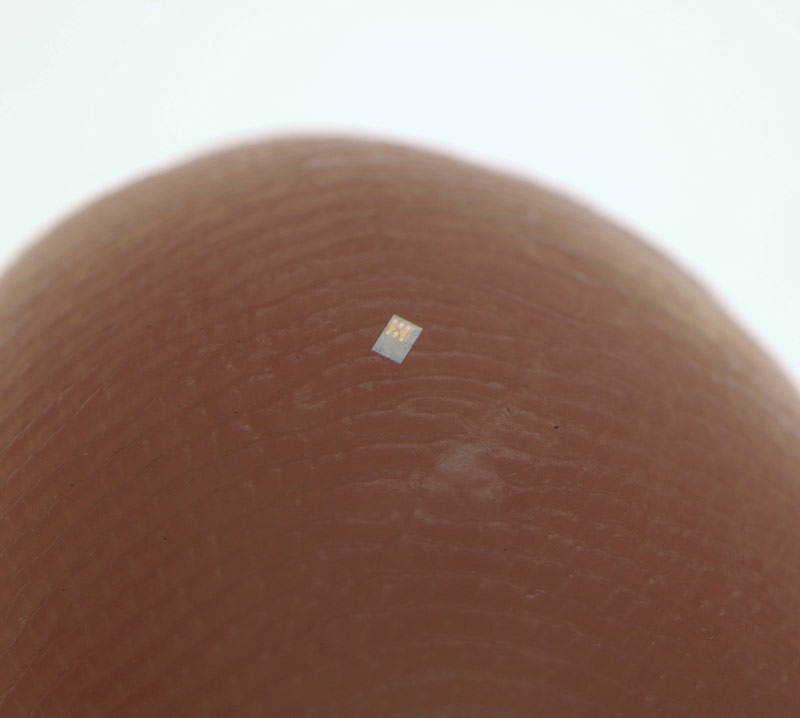

Microelectronics, smaller than a grain of sand— are high-tech, components that make up the backbone of the technology in our everyday lives. These microchips and semiconductors are powering modern society—from smartphones to space missions.

For over 70 years, Northrop Grumman’s Microelectronics Center has led the way in this rapidly advancing field. Our two U.S.-based, government-trusted manufacturing facilities and state-of-the-art packaging location set industry standards, delivering millions of defense and commercial microelectronics annually.

Our dual-use design and manufacturing approach enhances every stage of development, production, testing and integration, ensuring accelerated processes that lead to reliable products. With innovative design and precise fabrication, our mission-tailored solutions deliver exceptional performance to meet the most demanding challenges.

Highlights and Insights

American-Made Microelectronics

Discover key locations across the United States that are integral to Northrop Grumman's storied history and lasting impact in microelectronics. This interactive map showcases our commitment to innovation and excellence nationwide.

Trusted by the U.S. government, with multiple secure facilities on U.S. soil.

Mighty in the Microscopic

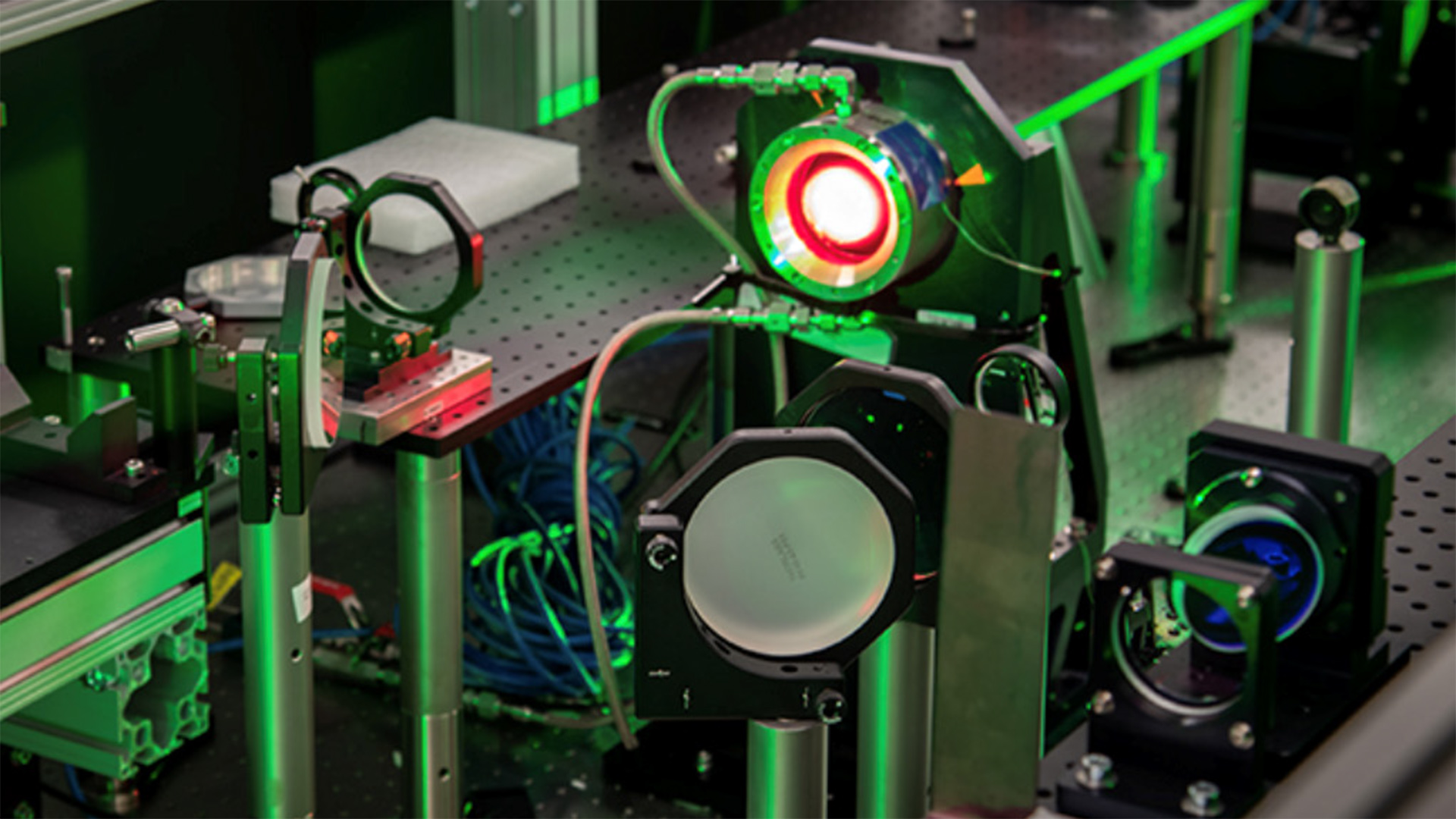

Unleashing Superconducting Superpowers

Our superconducting digital logic family allows our solutions extremely low operating temperatures for high-speed and energy-efficient computation. Using streamlined, precise fabrication processes ensures top-notch quality and rapid production, for high-performance defense microelectronics.

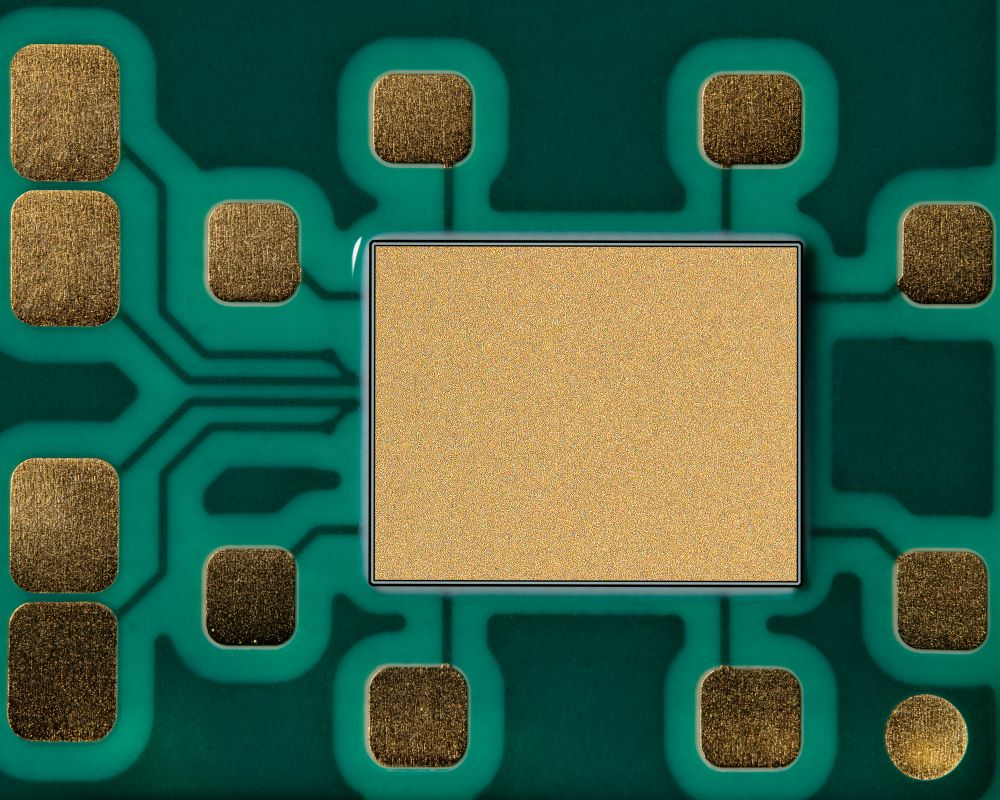

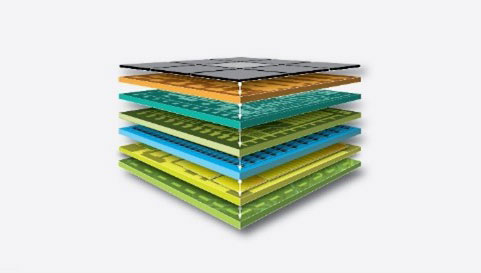

Revolutionizing Radio Frequency with SLCFET

Our Super-Lattice Castellated Field Effect Transistor (SLCFET), invented at our Advanced Technology Lab, is a world-record, groundbreaking radio frequency (RF) switch. The change in traditional model led to a 3D layered structure which can handle a wider range of frequencies with minimal power loss, addressing a 30-year gap in RF switch advancement.

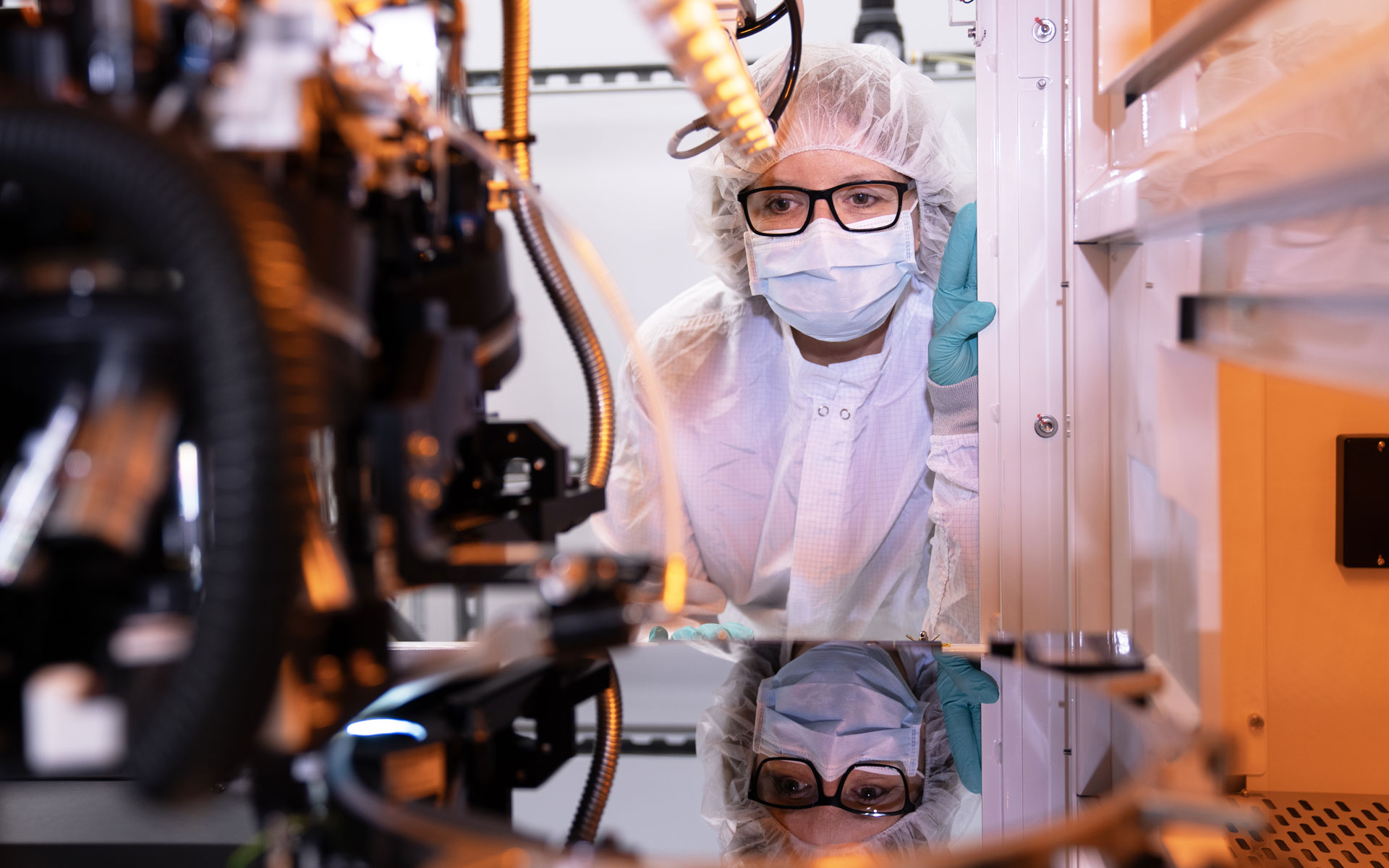

The Process for Precision

How one engineer transformed semiconductor chip validation through standardization and collaboration.

From Mops to Micro

“This is where I want to be,” Paul says as he joins his engineering colleagues, down the hall from the janitor’s closet which once held the keys to his success.

Leading U.S. Innovation with Powerful Microchips

Reviving U.S. leadership in cutting-edge technologies begins with the smallest element: the microchip.

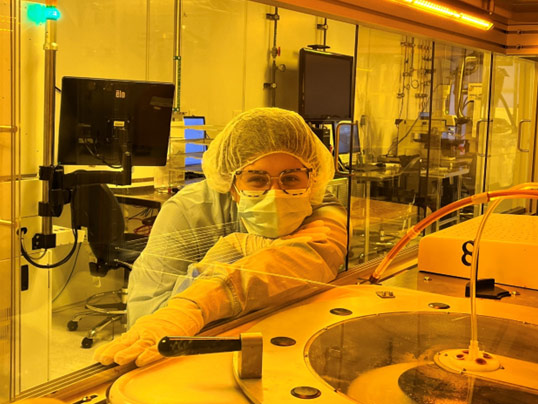

The Passion of a Pioneer

One woman’s commitment to the quality of Northrop Grumman’s microelectronics solutions.

Quick Chip

1,000 times faster than the chips in your cell phone, microscopic in size and enabling high speed secure communications for DoD missions.

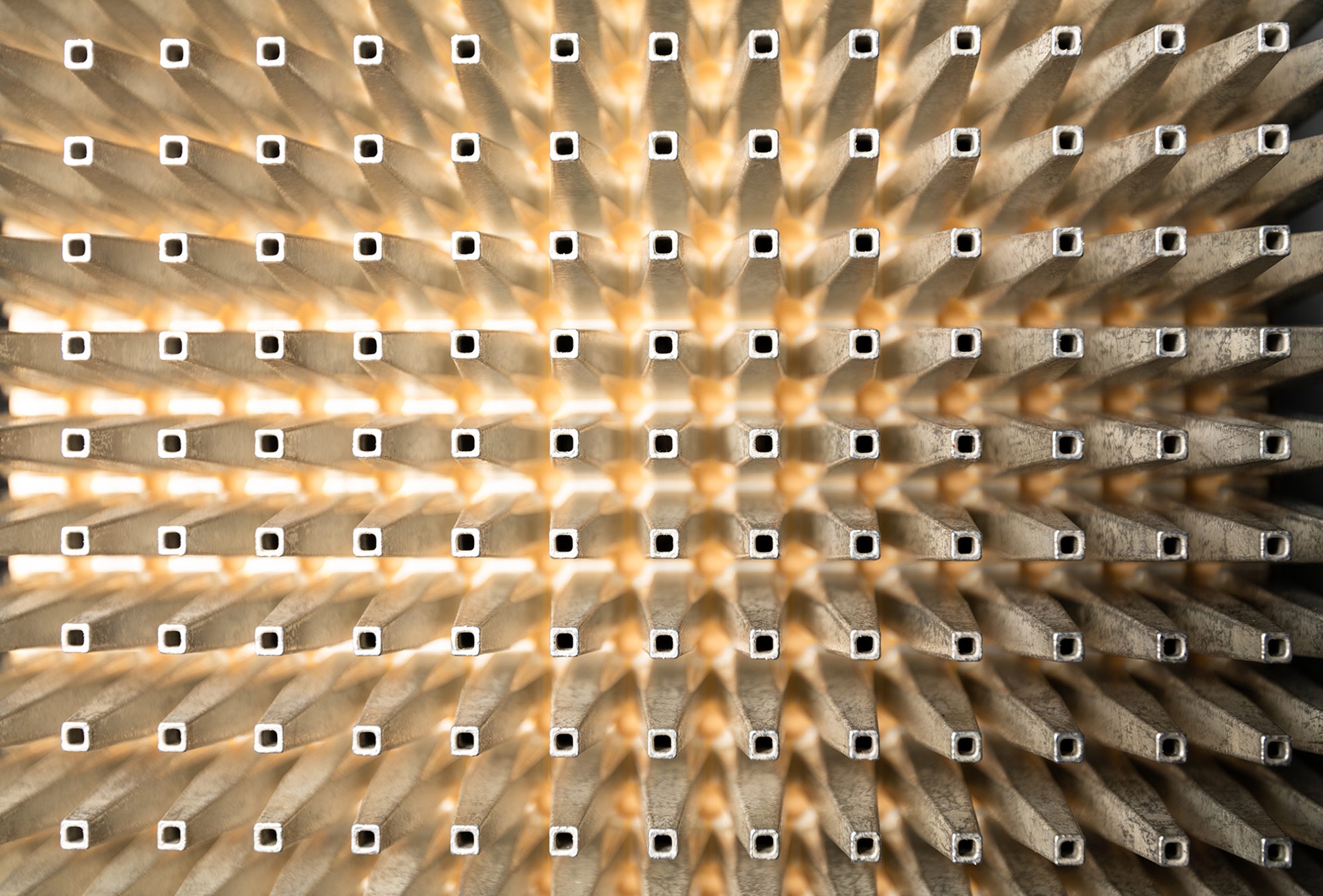

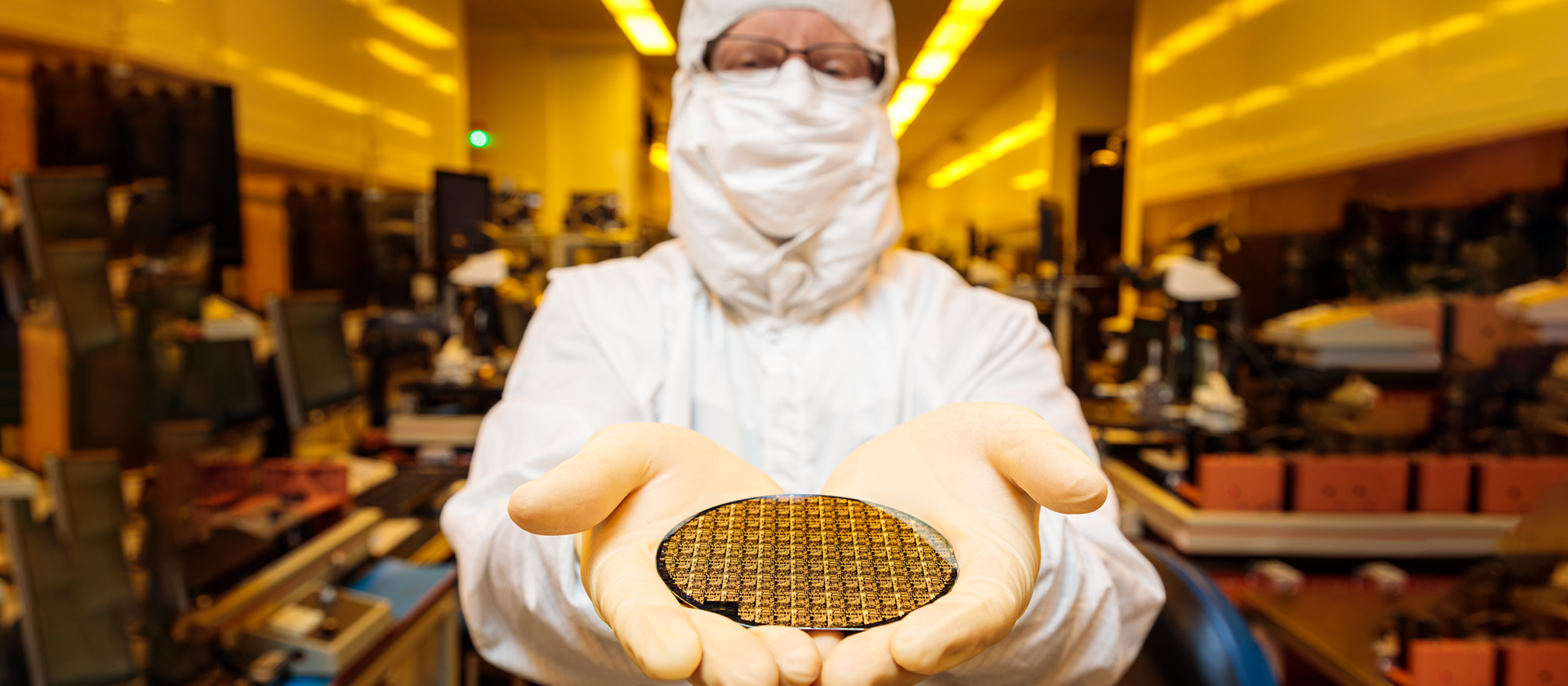

Paving the Way in Stacking and Packaging

Northrop Grumman, led by the Texas Institute for Electronics is strengthening U.S. semiconductor manufacturing using unique packaging and stacking techniques for microchips.

Prickly Progress

The prickly cactus plant sparked an idea to fine-tune high-tech avionics for one of the most advanced aircraft in the sky.

Mighty Microelectronics Team

With over 80 U.S. patents and 49 innovation awards, our strength lies in our people, not just our tools. Our purpose-driven culture empowers employees to create groundbreaking solutions, drive continuous improvement and embrace a digital-first approach.

Contact the Microelectronics Team

Have questions about how Northrop Grumman’s Microelectronics Centers can solve your toughest problems? We are here to answer them.

Telephone: 310-814-5000